Open type TBM tunneling cycle division method, surrounding rock grade prediction method and lithology prediction method

An open-type, tunneling speed technology, applied in prediction, neural learning methods, earthwork drilling and mining, etc., can solve the problems of surrounding rock grade and poor prediction accuracy of lithology, and achieve the effect of accurate division and accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

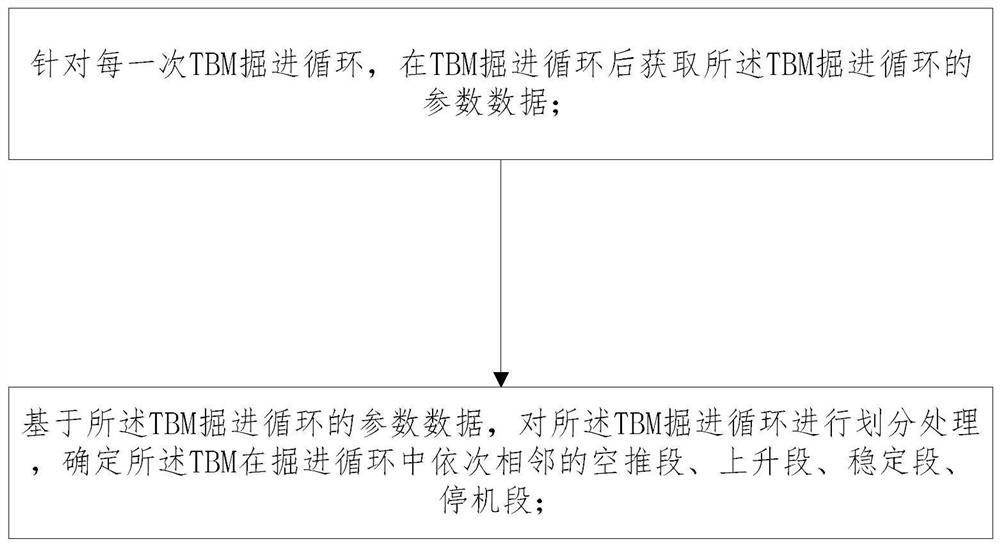

[0124] First, see figure 1 , an embodiment of the present invention provides a method for dividing an open TBM excavation cycle, including:

[0125] A1. For each TBM excavation cycle, acquire parameter data of the TBM excavation cycle after the TBM excavation cycle.

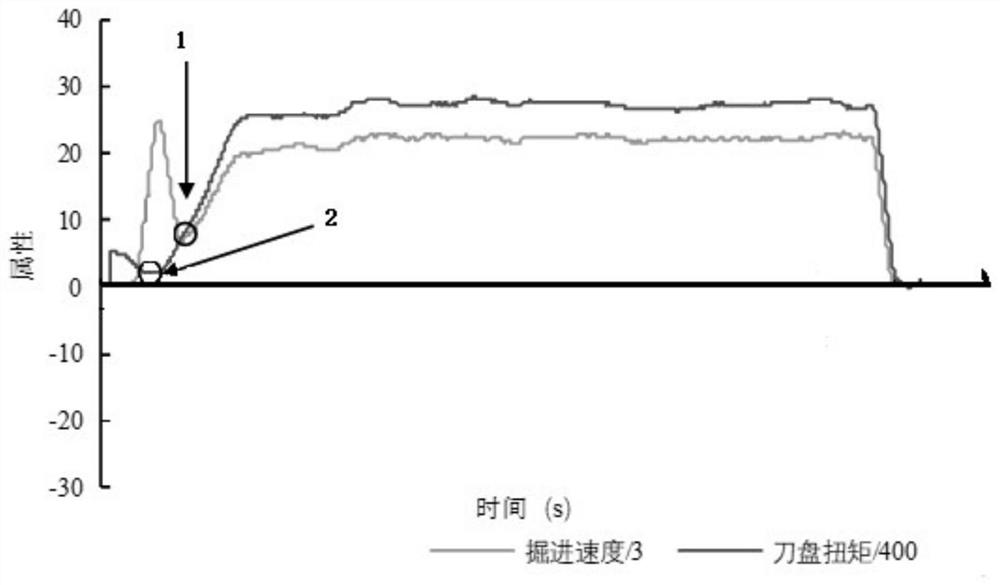

[0126] The TBM excavation cycle parameter data includes: cutterhead torque data, excavation speed data, and cutterhead rotational speed data in the TBM excavation cycle.

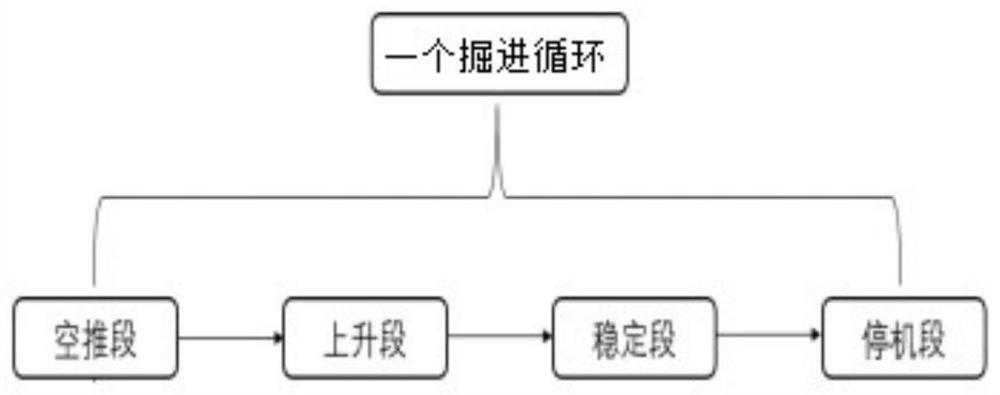

[0127] A2. Based on the parameter data of the TBM excavation cycle, the TBM excavation cycle is divided and processed, and the TBM is determined to be successively adjacent in the excavation cycle. figure 2 shown.

[0128] Said A2 includes:

[0129] A2-1. Based on the cutter head rotation speed data in the TBM excavation cycle, determine the starting point of the hollow push section and the end point of the shutdown section of the TBM excavation cycle.

[0130] Wherein, the starting point of the hollow thrust section of the TBM excavation ...

Embodiment 2

[0162] see Figure 4 On the other hand, the embodiment of the present invention also provides a method for predicting the grade of surrounding rock, the method comprising:

[0163] S1. Obtain second data in each excavation cycle to be predicted.

[0164] The second data includes: the mean value of the final input characteristic data corresponding to the first time period in each excavation cycle determined by using the above-mentioned division method of the open TBM excavation cycle.

[0165] Wherein, the first period of time in the excavation cycle includes: an ascending segment and a stable segment in the excavation cycle.

[0166] The final input features are: cutterhead speed, steel arch pump pressure, shoe pump pressure, shoe pressure, main engine belt conveyor pump pressure, right shoe rolling angle, top shield pressure, unit penetration torque, Average tunneling speed, roll angle of left leg shoe, pitch angle of front shield and propulsion speed in each cycle;

[016...

Embodiment 3

[0186] see Image 6 , the present embodiment also provides a lithology prediction method, the method comprising:

[0187] Q1. Obtain the third data in each excavation cycle of the plurality of excavation cycles to be predicted.

[0188] The third data includes: the optimal characteristic data corresponding to the first 15 seconds of the ascending segment in each excavation cycle determined by adopting the above-mentioned division method of the open TBM excavation cycle.

[0189] Among them, the optimal features include: gear seal outer seal pressure, gear seal inner seal pressure, shoe pump pressure, right shoe rolling angle, left shoe rolling angle, host belt conveyor speed, top shield pressure, front shield Pitch angle, cutterhead speed.

[0190] Q2. Input the third data into the trained global attention mechanism-based LSTM network multi-layer network structure model to obtain prediction results.

[0191] Wherein, the LSTM network multi-layer network structure model base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com