Vertical integrated unit light emitting diode

A technology of light-emitting diodes and integrated units, applied in electrical components, nanotechnology, electro-solid devices, etc., can solve the problems of LED light efficiency, heat dissipation and stability limitations, etc., to improve light extraction efficiency, optimize heat dissipation performance, and solve luminous Effects of uneven problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

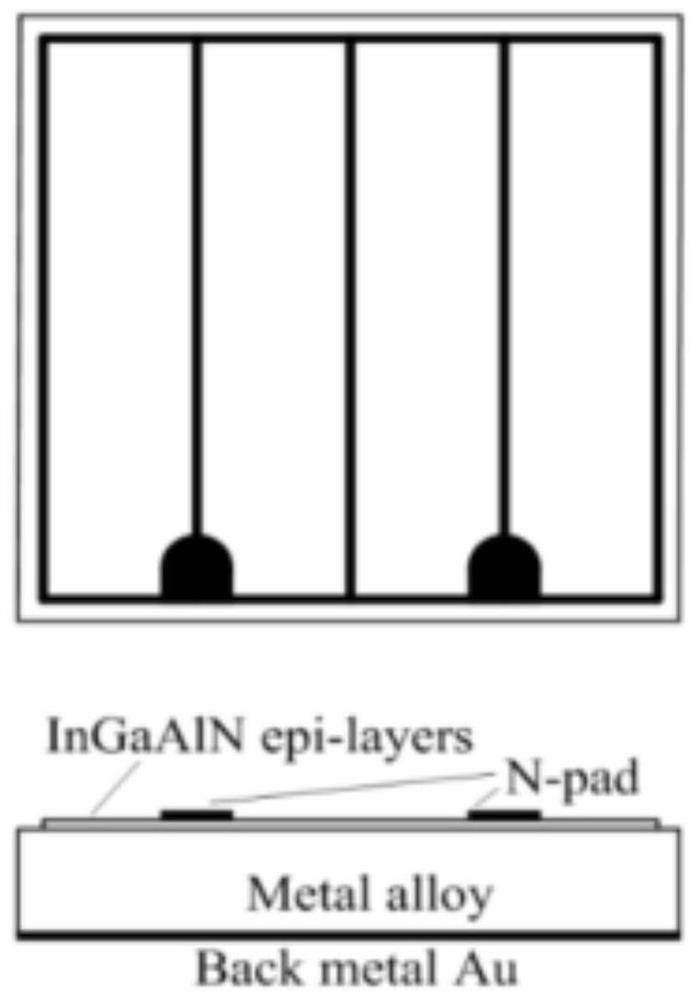

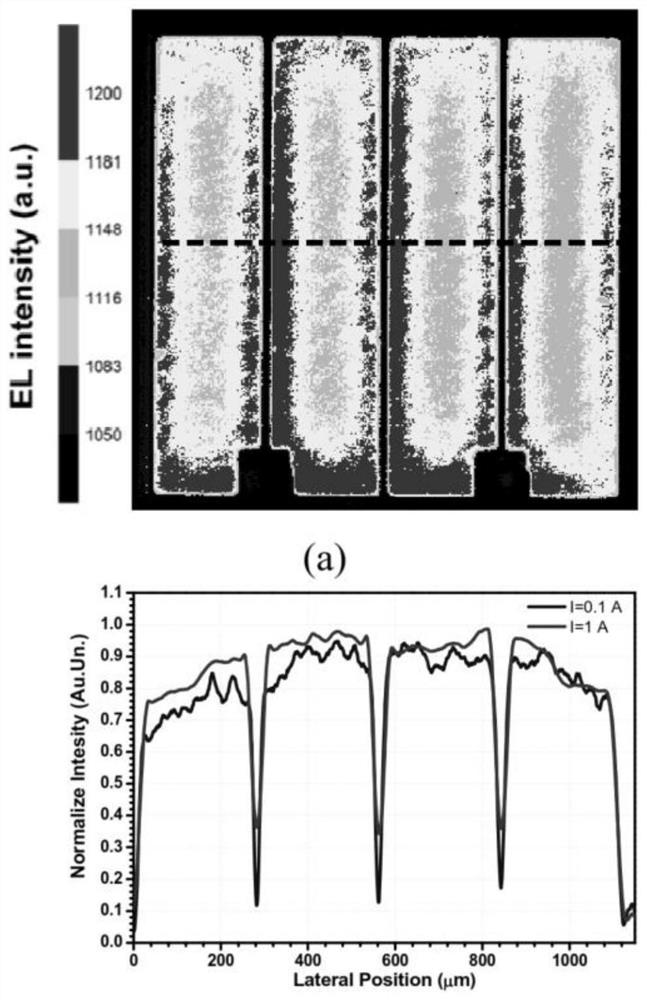

[0060] This embodiment provides a vertically integrated unit light-emitting diode, including: a second conductivity type electrode 1, an overall mesa structure 6 composed of a diode unit mesa structure, a groove 7 and a diode unit 8, a second conductivity type electrode line 9, and a pad 10. The second conductivity type electrode 1 is an N-type conductivity electrode. The width of the groove is 0.1 micron, and the depth is 0.01 micron. The groove is located between the diode units, and a linear electrode line is laid in the groove. The width of the electrode line is 0.01 micron to 10 micron, and the thickness is 0.01 micron to 10 micron. The N-type conductive electrode is in ohmic contact with the top of the diode unit and is connected to the pad through a strip-shaped electrode line. The number of pads is 1, and the shape is an irregular polygon with an arc-shaped side, located on the short edge of the mesa structure. The pad thickness is 0.1 micron and the width is 50 micro...

Embodiment 2

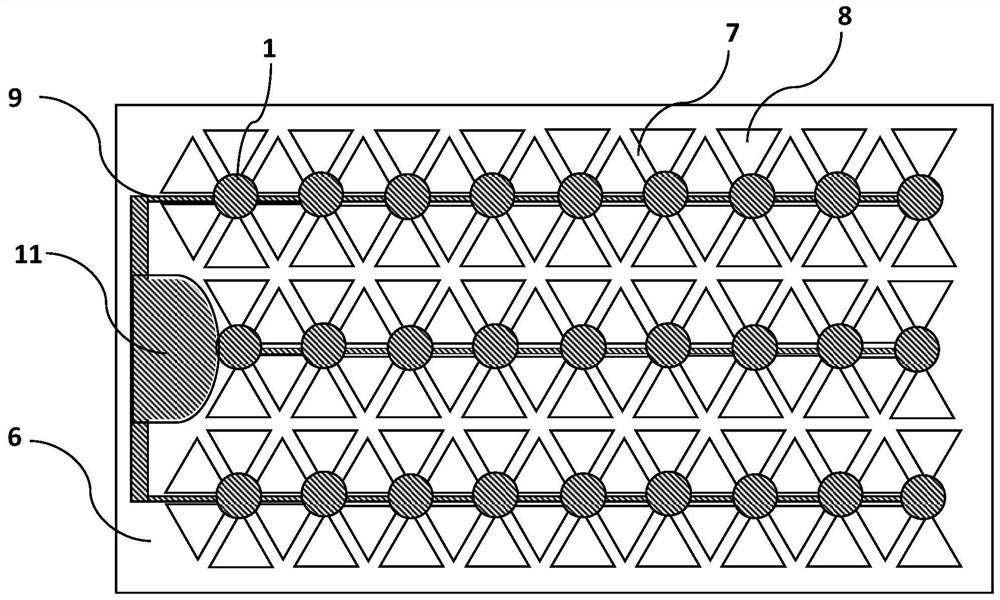

[0068] This embodiment provides a vertically integrated unit light emitting diode, such as Figure 8 As shown, it includes: a second conductivity type electrode 1, an overall mesa structure 6, a trench 7, a diode unit 8, a second conductive type electrode line 9 and a pad 10, and the second conductive type electrode 1 is an N-type conductive electrode. The width of the groove is 1 micron, and the depth is 0.1 micron. The groove structure is located between the diode units, and a linear electrode line is laid in the groove. The width of the electrode line is 0.1 micron to 1 micron, and the thickness is 0.1 micron to 1 micron. The N-type conductive electrode is in ohmic contact with the top of the diode unit and is connected to the pad through a strip-shaped electrode line. The number of pads is 1, the shape is a rectangle with rounded corners, it is located in the middle of the table, the thickness of the pad is 1 micron, and the width is 5 microns.

[0069] The chip includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com