Connection terminal punch forming device

A technology for stamping and forming and connecting terminals, which is applied in the field of stamping and forming devices for connecting terminals, can solve the problems of inaccurate stamping distance of connecting terminals, slow work efficiency, and shorten the service life of stamping knives, so as to avoid repeated disassembly, improve work efficiency, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

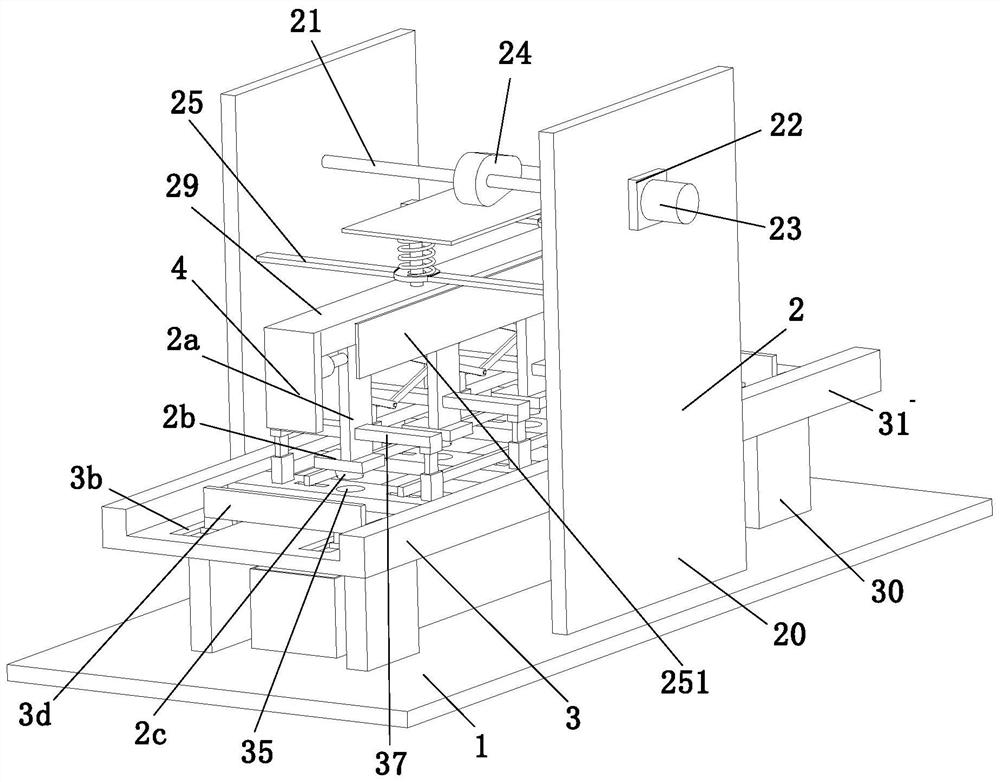

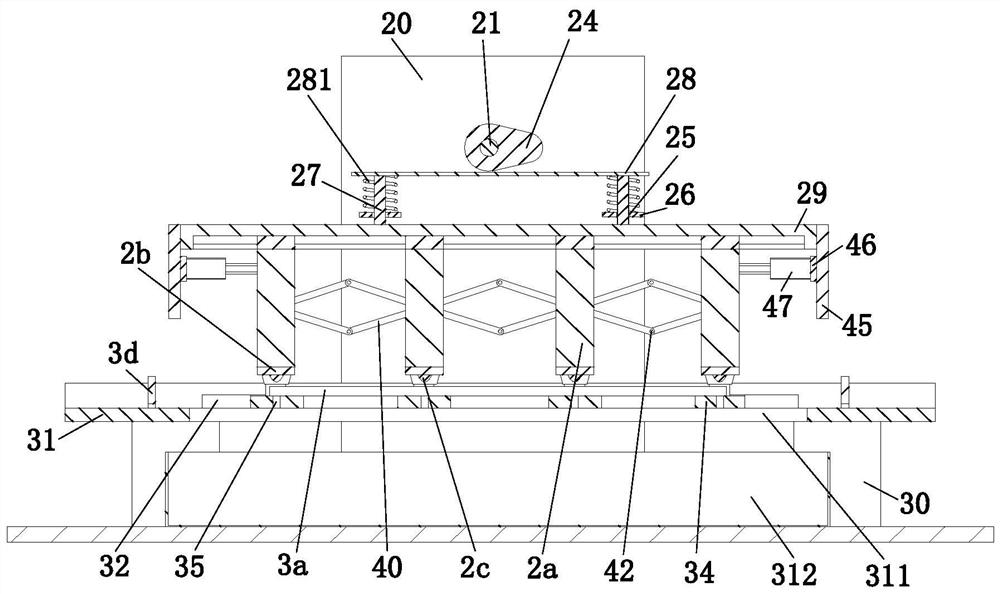

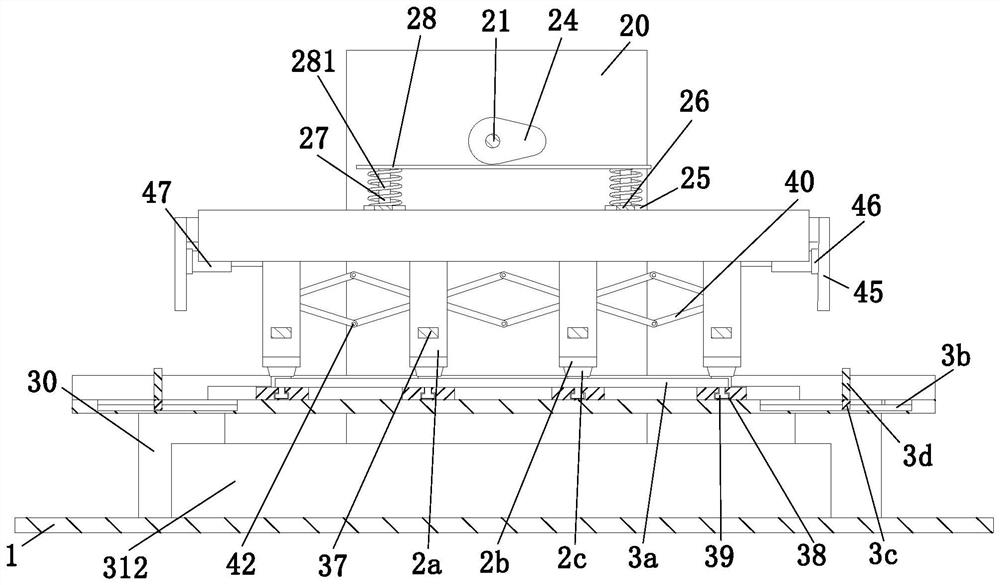

[0024] like Figure 1 to Figure 6 As shown, a connecting terminal stamping and forming device includes a workbench 1, a stamping mechanism 2, a fixing mechanism 3 and an adjusting mechanism 4. A stamping mechanism 2 is arranged above the workbench 1, and a fixing mechanism 3 is arranged below the stamping mechanism 2. , The stamping mechanism 2 is provided with an adjustment mechanism 4 .

[0025]The stamping mechanism 2 includes a vertical plate 20, a rotating shaft 21, a base 22, a motor 23, a cam 24, a connecting rod 25, a ring 26, a moving rod 27, a moving plate 28, a lifting plate 29, a vertical rod 2a, the connecting plate 2b and the blade 2c, the upper end of the workbench 1 is symmetrically installed with vertical plates 20 front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com