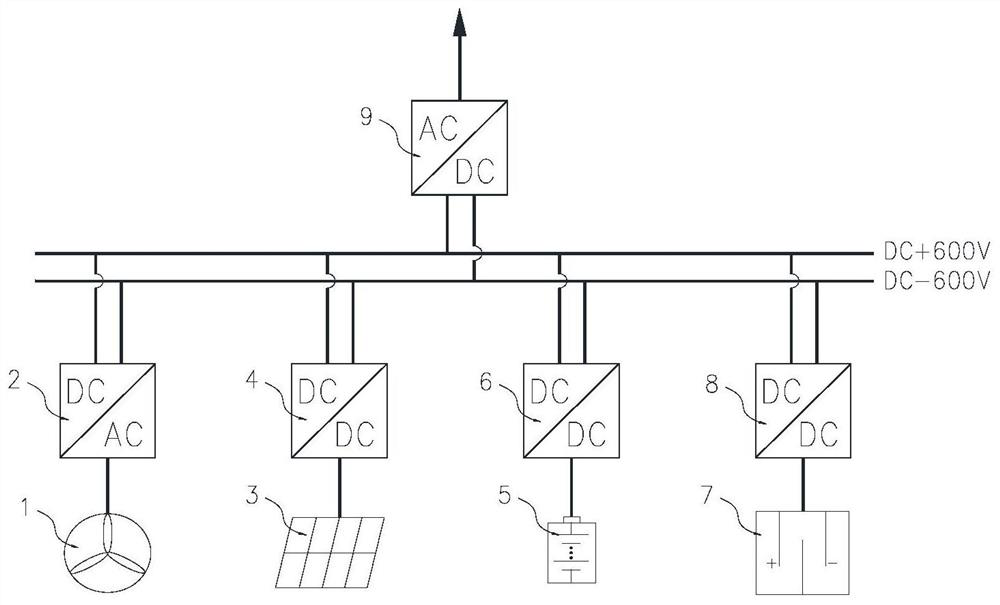

Wind-solar complementary hydrogen production power station system based on +/-600V direct current microgrid

A DC micro-grid and wind-solar hybrid technology, applied in the direction of DC network circuit device, AC network circuit, parallel operation of DC power supply, etc., can solve the problems of increasing system complexity, reducing energy conversion efficiency, and high cost of hydrogen energy production. The effect of reducing power conversion links, improving comprehensive energy utilization efficiency, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is described in further detail:

[0023] like figure 1 As shown, a wind-solar complementary hydrogen production power station system based on a ±600V DC micro-grid includes a wind power generation module 1, a photovoltaic power generation module 3, an energy storage module 5, and a water electrolysis hydrogen production module 7. The wind power generation module 1 includes Wind turbines, frequency conversion devices and fan monitoring and protection devices. The wind power generation module 1 is connected to a ±600V DC bus through a wind power rectifier 2 and is used as a new energy power generation terminal to supply power. The photovoltaic power generation module 3 includes a photovoltaic cell assembly, a DC confluence device and a photovoltaic on-site monitoring device. Module 3 is connected to the DC bus through a photovoltaic DC converter 4 with MPPT function and serves as a new energy power generation ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com