False tooth processing system

A processing system and denture technology, applied in the direction of cleaning teeth, medical science, dentistry, etc., can solve the problems of high temperature, inconvenient operation, cooling and cooling of the discharge disc and support disc, and achieve improved utilization and safe use. Convenience and the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

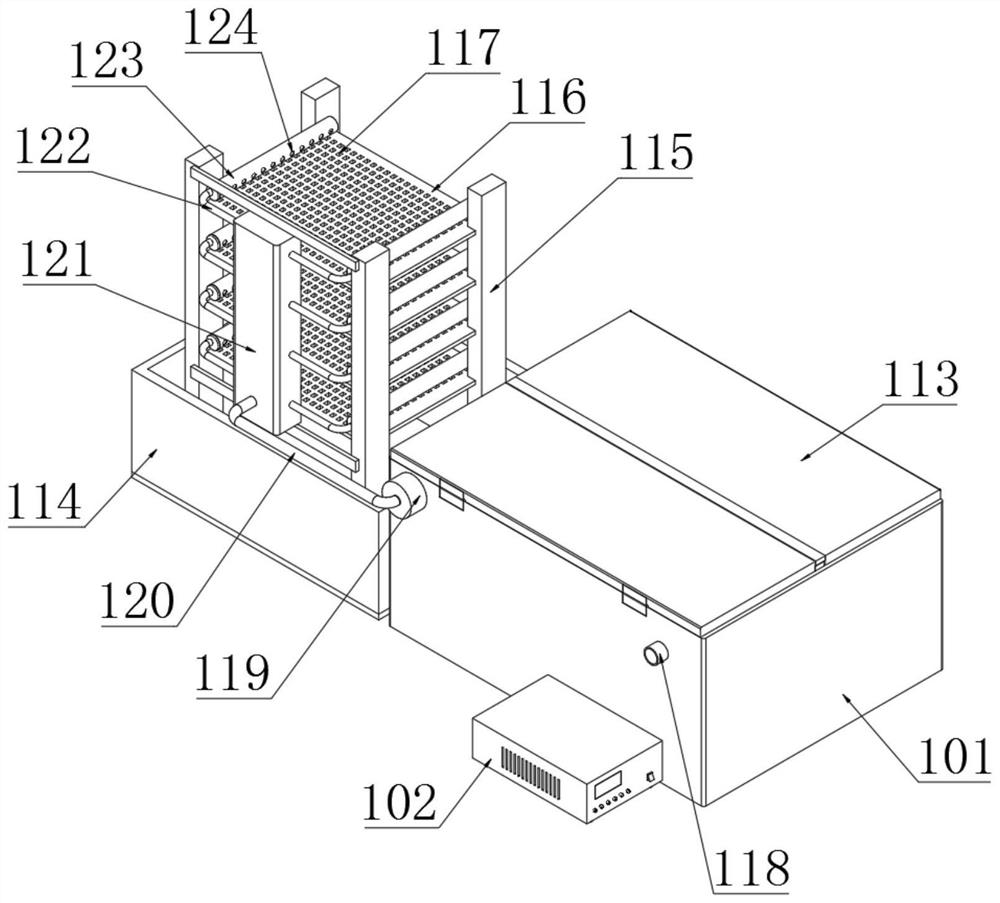

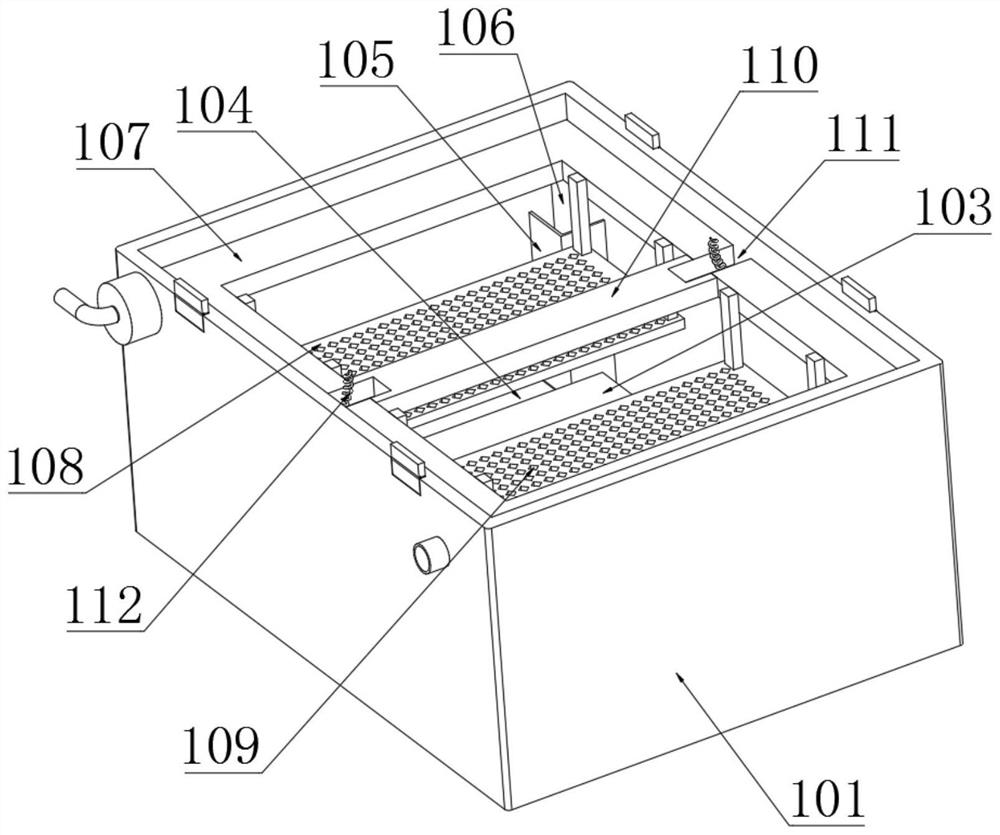

[0045] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a denture processing system, including a pretreatment device 100 and a sintering device 200. After the denture is cleaned by the pretreatment device 100, the sintering process is performed by the sintering device 200. Cleaning tank 101, one end of ultrasonic cleaning tank 101 bottom is fixedly connected with ultrasonic generator 102, and the bottom end of ultrasonic cleaning tank 101 interior is equipped with ultrasonic vibrating plate 103, and ultrasonic generator 102 is connected with ultrasonic vibrating plate 103, and ultrasonic cleaning tank 101 The bottom of the ultrasonic cleaning tank 101 is located on both sides of the ultrasonic vibration plate 103, and ceramic heating plates 104 are symmetrically and fixedly installed. Waterproof tanks 105 are installed at the four corners inside the ultrasonic cleaning tank 101, and electric telescopic rods are fixedly installed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com