Method for checking damage of dust collecting bag

A bag and breakage technology, applied in the fields of dust collectors, separation methods, chemical instruments and methods, etc., can solve the problems of less or cut-off pulverized coal injection in blast furnaces, affecting the stability of blast furnaces, and many misjudgments, etc., and achieves the accuracy of investigation. High, the effect of shortening the time of replacing the dust bag and reducing the replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

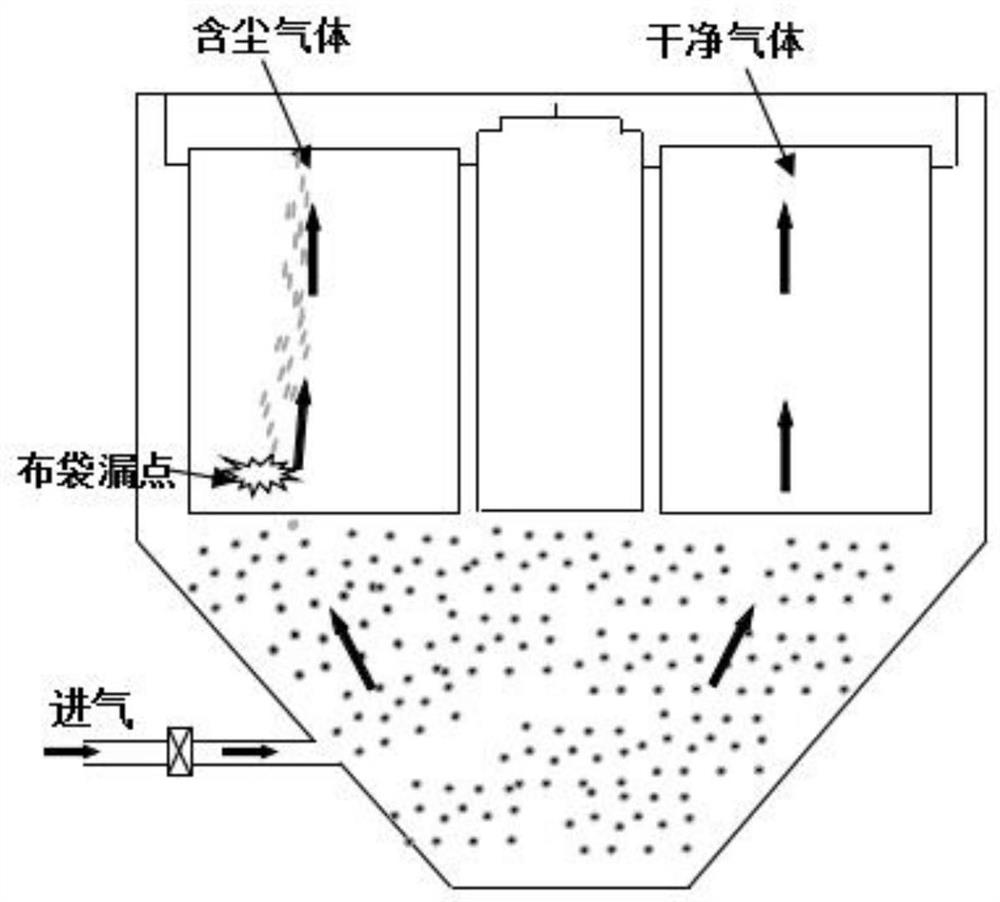

[0026] A method for checking the damage of the dust bag, comprising the following steps:

[0027] S1. According to the dust exceeding the standard at the outlet of the coal exhaust fan, it is confirmed that the cloth bag needs to be checked.

[0028] S2, open the big cover, close the lifting valve cover, and cut off other air chambers.

[0029] S3. The inspector communicates with the operator through the walkie-talkie to open the air intake valve of the bag box, and visually inspects whether there is dust-mixed black gas discharged from each bag of the air chamber, so as to accurately determine whether there is a leak.

[0030] S4. Sequentially check each working room of the bag box, and count the replacement of the bag.

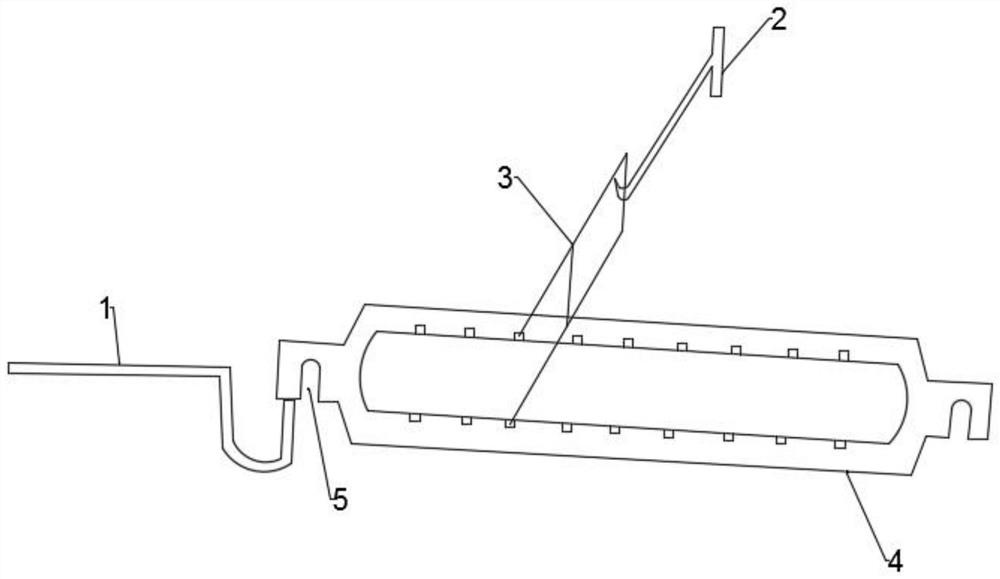

[0031] S5. When pulling out the cloth bag, contact and start the coal discharge fan, and the system will generate negative pressure (not too high, the flow rate of the coal discharge fan should be controlled at about 40000m3 / h, which means that the on-site ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap