Raw material processing device for high-end equipment manufacturing

A technology for processing equipment and raw materials, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problems of increasing the work intensity of the staff and the mixing is not uniform enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

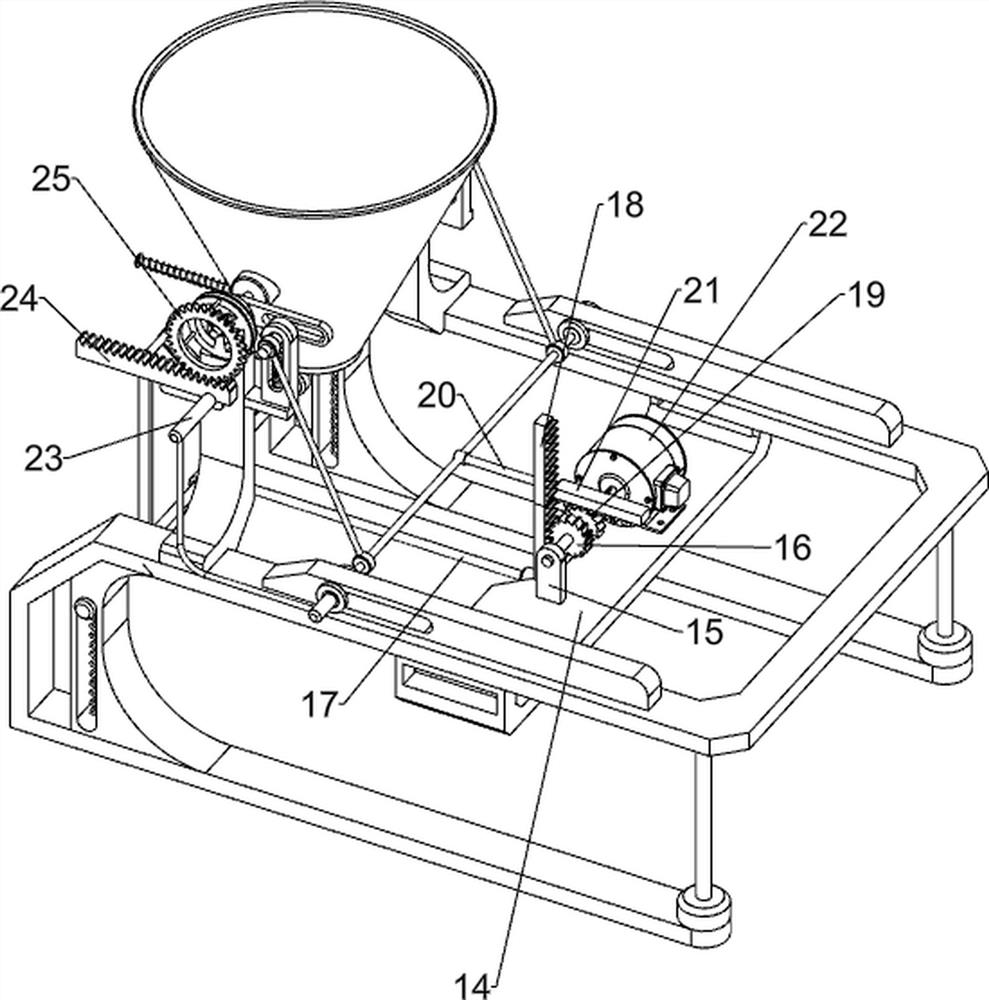

[0026] Such as figure 1 As shown, a raw material processing device for high-end equipment manufacturing includes a base plate 1, a support plate 2, a stirring mechanism 3, a shaking mechanism 4, and a feeding mechanism 5. The base plate 1 is provided with a support plate 2, and the rear side of the support plate 2 is provided There is a stirring mechanism 3, a shaking mechanism 4 is arranged in the middle of the support plate 2, and a feeding mechanism 5 is arranged at the bottom of the stirring mechanism 3.

[0027] When it is necessary to process the composite materials manufactured by high-end equipment, the staff puts the composite materials into the stirring mechanism 3, and then the staff rotates the stirring mechanism 3, and the stirring mechanism 3 rotates to stir the composite materials, and another staff pulls the shaking mechanism forward 4. The shaking mechanism 4 slides forward to drive the stirring mechanism 3 to shake up and down. After the composite material is...

Embodiment 2

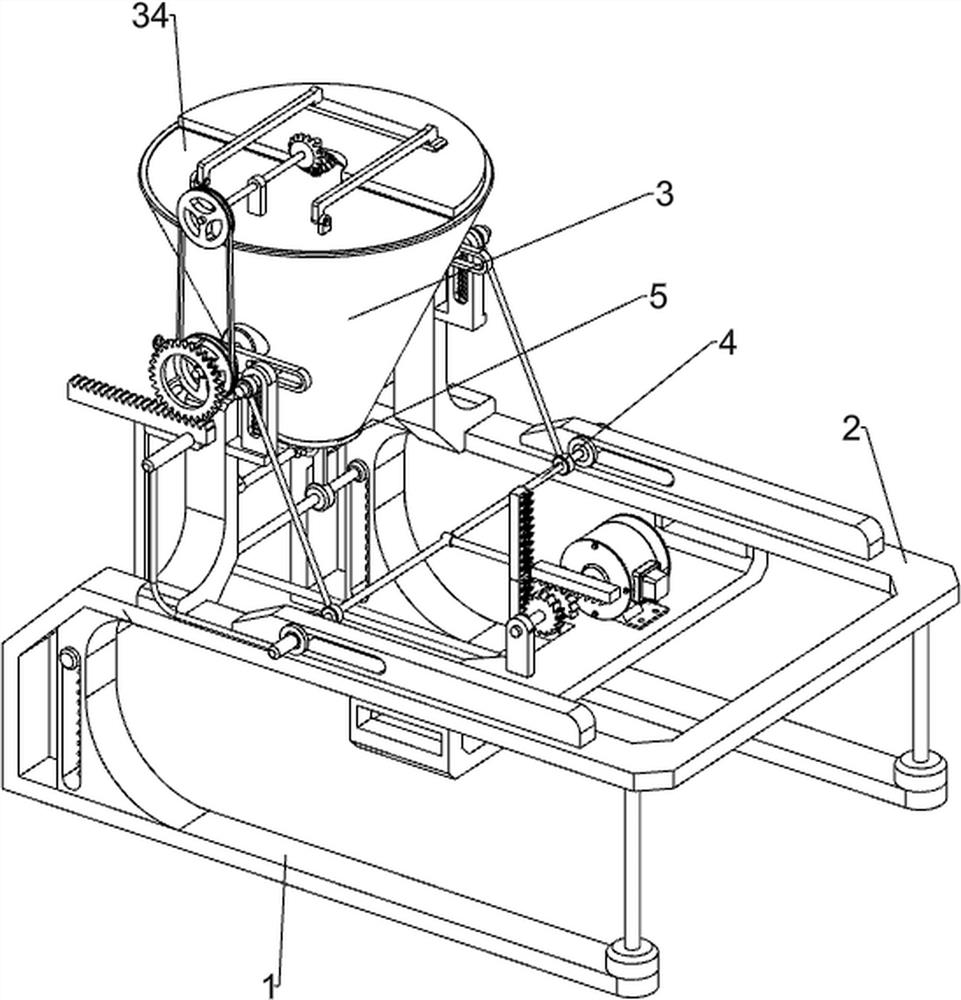

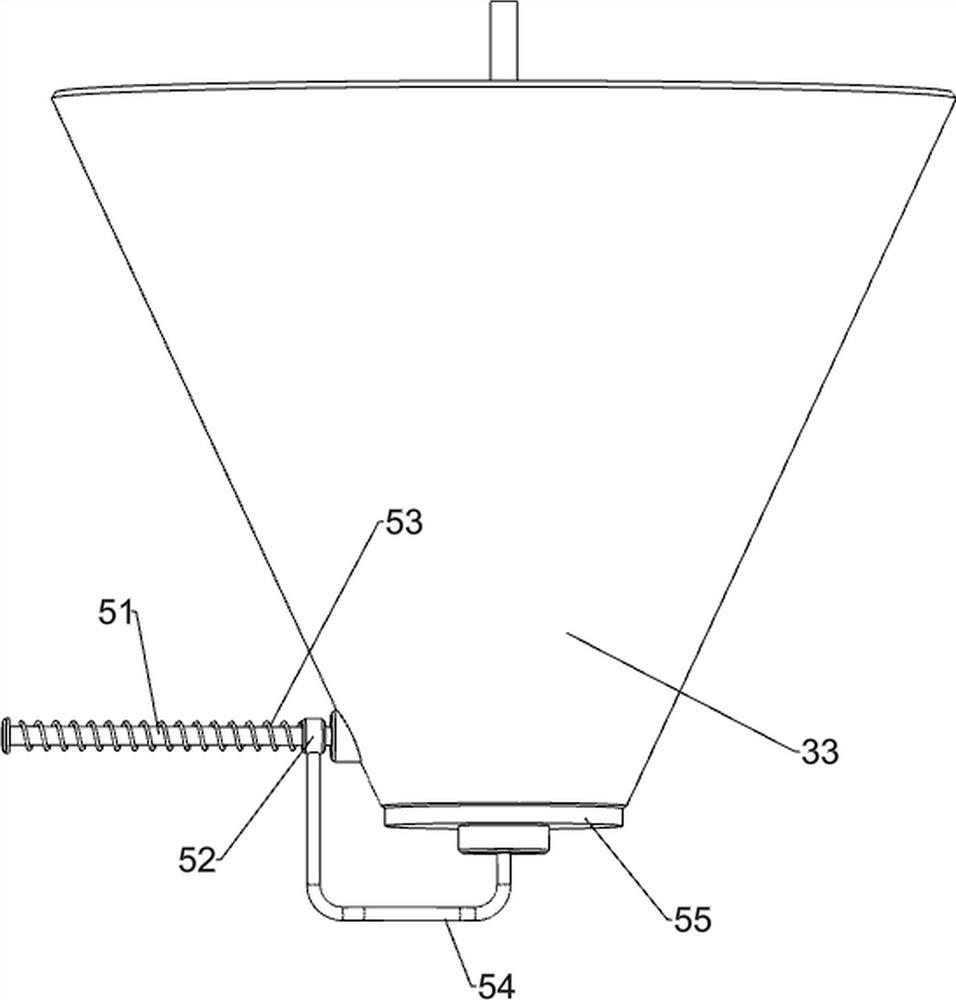

[0029] Such as figure 2 with image 3As shown, on the basis of Embodiment 1, the stirring mechanism 3 includes a first bearing seat 31, a first rotating shaft 32, a mixing bucket 33, a fixed plate 34, a second bearing seat 35, a second rotating shaft 36, and a stirring head 37 , the third bearing seat 38, the third rotating shaft 39, the bevel gear set 310, the one-way bearing 311 and the belt transmission device 312, the rear side of the support plate 2 is symmetrically provided with the first bearing seat 31, between the two first bearing seats 31 The rotary type is provided with a first rotating shaft 32, the first rotating shaft 32 is provided with a mixing bucket 33, the top of the mixing bucket 33 is provided with a fixed plate 34, the mixing bucket 33 is provided with a second bearing seat 35, and the rotating type on the second bearing seat 35 A second rotating shaft 36 is provided, a stirring head 37 is arranged on the second rotating shaft 36, a third bearing seat ...

Embodiment 3

[0036] Such as Figure 4 and Figure 5 As shown, it also includes a fourth slider 6, a third elastic member 7, a fourth fixed rod 8, a fifth fixed rod 9, a sixth fixed rod 10, a seventh fixed rod 11, a wedge-shaped sliding rod 12 and a second gear Plate 13, the left and right sides of the bottom plate 1 are provided with a word chute, and the fourth slider 6 is slidably arranged in the two word chute, and the side of the two fourth slider 6 is connected with the bottom of the two word chute. The third elastic member 7 is arranged between them, the fourth fixed rod 8 is arranged between the two fourth sliders 6, the fifth fixed rod 9 is arranged on both sides of the fourth fixed rod 8, and the two fifth fixed rods 9 tops are all provided with the sixth fixed rod 10, the third fixed rod 54 is provided with the seventh fixed rod 11, the seventh fixed rod 11 two ends are all provided with wedge-shaped slide bar 12, two sixth fixed rods 10 and two The wedge-shaped sliding rod 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com