Self-guiding transmission system for motor assembly

A transmission system and self-guided technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor product assembly quality stability, low efficiency of skylight motor assembly, high safety protection cost, etc., and achieve reasonable ergonomics and The effect of production line design, saving safety investment, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

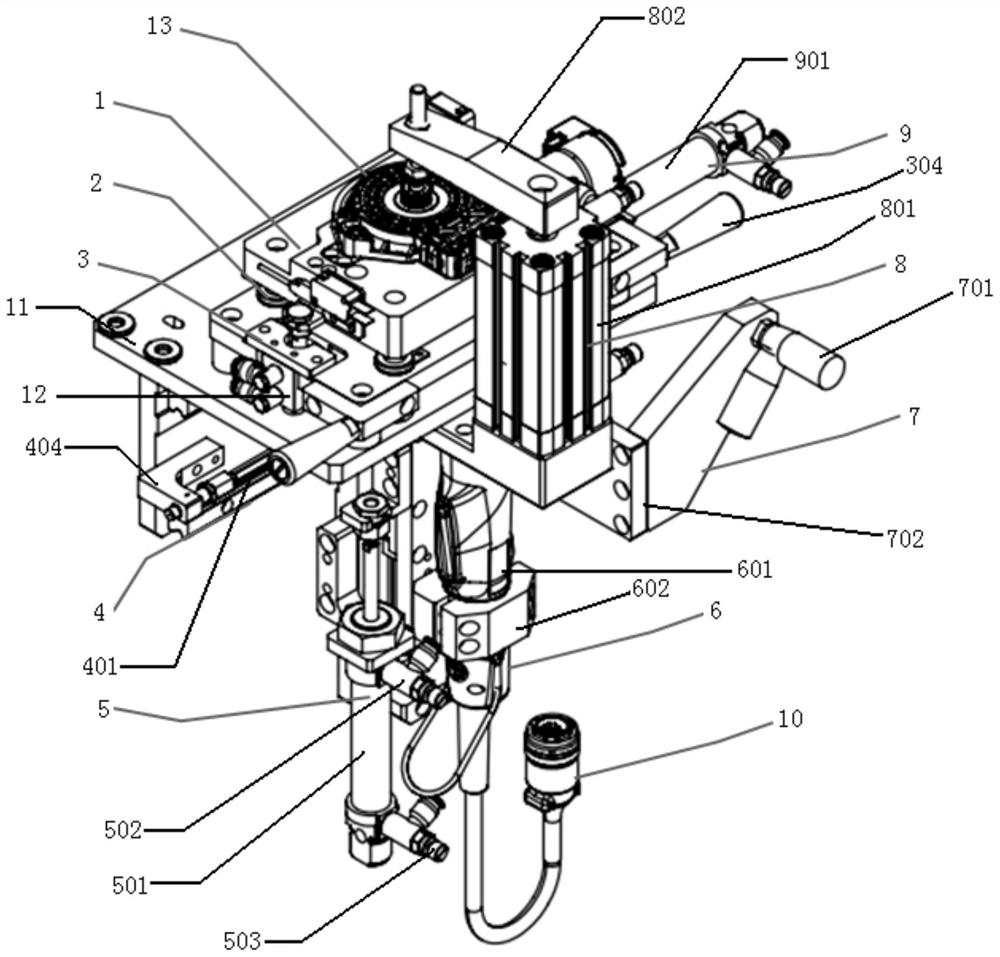

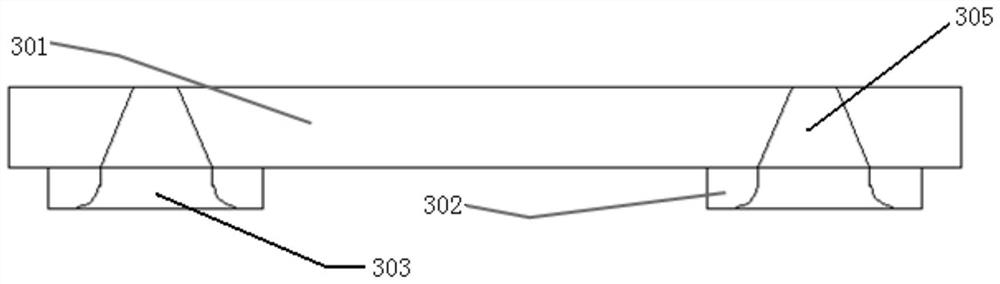

[0028] A self-guiding transmission system for motor assembly, including a positioning tool 1, a buffer adjustment mechanism 2, a guide device 3, a lateral position adjustment mechanism 4 of a tightening mechanism, a balance assist mechanism 5, a tightening mechanism 6, a manual backup mechanism 7, a pressing mechanism Tooling 8, stable thrust mechanism 9, controller 10 and workbench 11,

[0029] The upper part of the positioning tool 1 is provided with a groove matching the pre-assembled parts 13, which is used for the preliminary shape positioning of the raw material, and the positioning tool 1 is connected with the guide device 3 through the buffer adjustment mechanism 2;

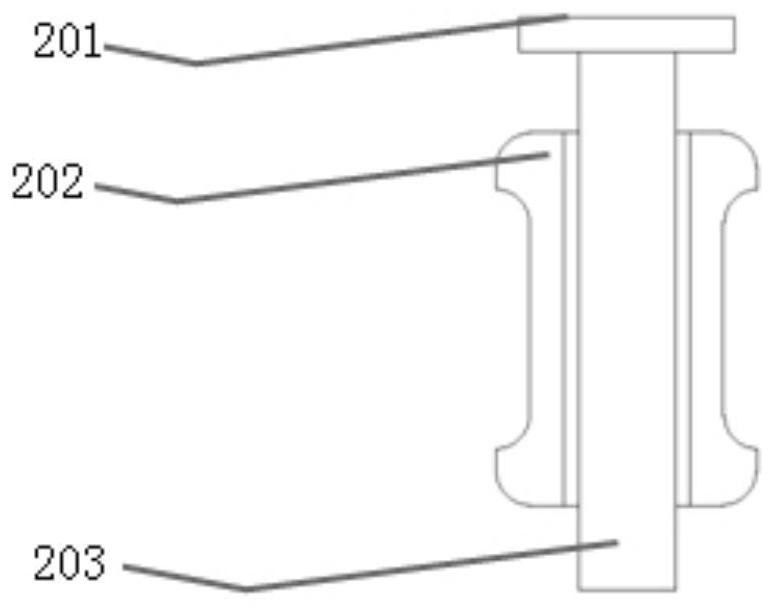

[0030] The buffer adjustment mechanism 2 includes a connecting head 201, an elastic block 202 and a threaded rod 203; the bottom of the connecting head 201 is fixedly connected with the upper part of the threaded rod 203, and the connecting head 201 is connected with the positioning tool 1; An elastic blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com