Tool for disassembling bearing outer ring of printing rubber roller

A technology of bearing outer ring and printing rubber roller, applied in the field of printing machinery, can solve the problems of rubber roller damage, time-consuming, wear of support bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

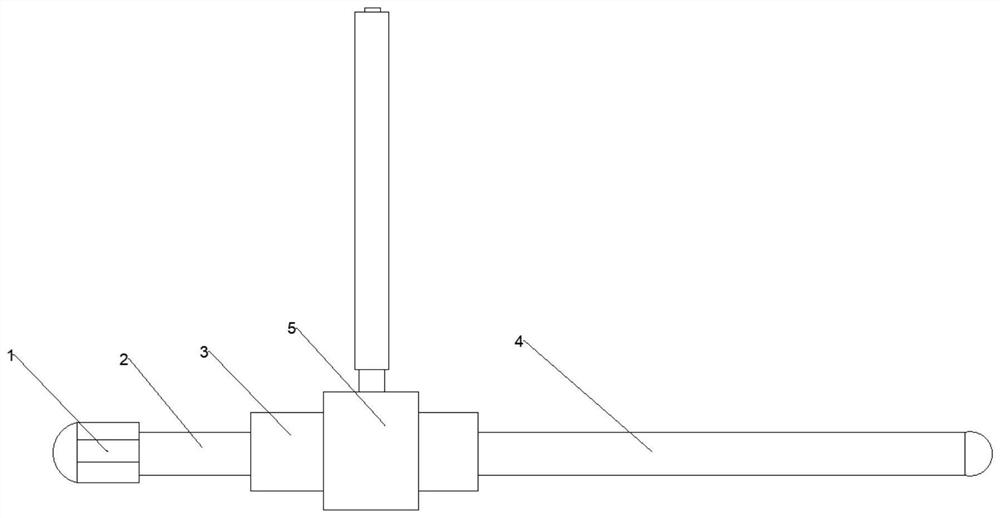

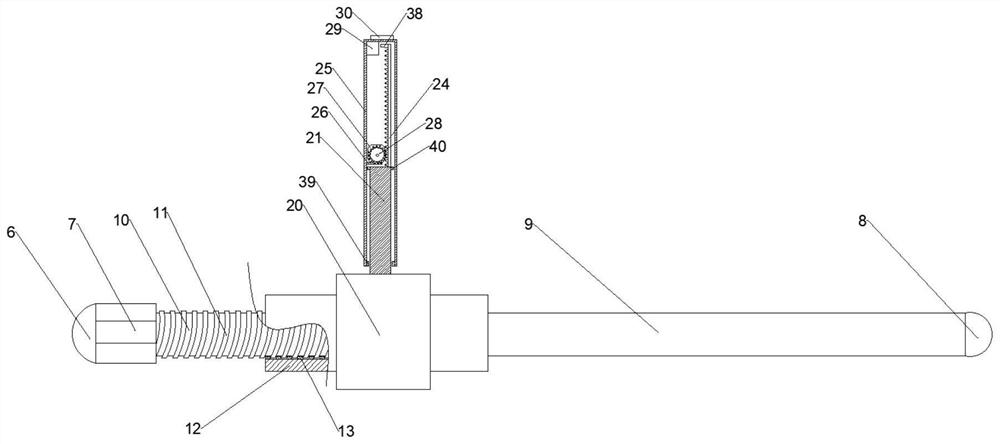

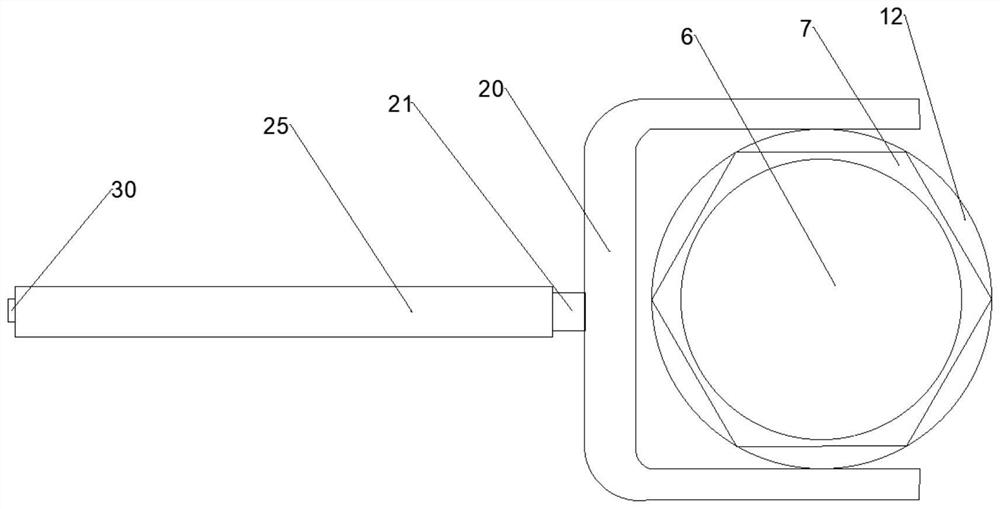

[0032] Please refer to Figure 1-3 , figure 1 It is a front view of a tool for disassembling the outer ring of printing rubber roller bearing according to the embodiment of the present invention; figure 2 It is a partial sectional view of a tool for removing the outer ring of a printing rubber roller bearing according to an embodiment of the present invention; image 3 It is a side view of a tool for removing the outer ring of a printing roller bearing according to an embodiment of the present invention.

[0033] This embodiment provides a tool for dismounting the outer ring of the printing rubber roller bearing, including a first ejector rod 1 in contact with the outer ring of the bearing, a connector 2 connected to the first ejector rod 1 , and a telescopic The connected sleeve joint 3, the second ejector rod 4 connected to the sleeve joint 3 and in contact with the outer ring of the bearing, and the electric punch 5 connected to the sleeve joint 3, wherein the diameter o...

Embodiment 2

[0036] Please refer to Figure 1-3 , figure 1 It is a front view of a tool for disassembling the outer ring of printing rubber roller bearing according to the embodiment of the present invention; figure 2 It is a partial sectional view of a tool for removing the outer ring of a printing rubber roller bearing according to an embodiment of the present invention; image 3 It is a side view of a tool for removing the outer ring of a printing roller bearing according to an embodiment of the present invention.

[0037] This embodiment improves a tool for removing the outer ring of the printing rubber roller bearing, which is basically the same as the tool for removing the outer ring of the printing rubber roller bearing in Embodiment 1. The difference between the two is mainly: the second ejector rod 4 includes a second contact section 8 that is in contact with the outer ring of the bearing and has an arc-shaped surface, and a second push section 9 that is connected to the second...

Embodiment 3

[0040] Please refer to Figure 1-3 , figure 1 It is a front view of a tool for disassembling the outer ring of printing rubber roller bearing according to the embodiment of the present invention; figure 2 It is a partial sectional view of a tool for removing the outer ring of a printing rubber roller bearing according to an embodiment of the present invention; image 3 It is a side view of a tool for removing the outer ring of a printing roller bearing according to an embodiment of the present invention.

[0041] This embodiment improves a tool for removing the outer ring of the printing rubber roller bearing, which is basically the same as the tool for removing the outer ring of the printing rubber roller bearing in Embodiment 1. The difference between the two is mainly: the first ejector rod 1 includes a first contact segment 6 that is in contact with the outer ring of the bearing and has an arc-shaped surface, and a first push segment 7 connected to the first contact seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com