Injection mold with cooling function

An injection mold and functional technology, applied in the field of injection molds with cooling function, can solve the problems of affecting the yield of the mold, the mold release cannot be carried out smoothly, and the temperature cannot be effectively isolated, so as to reduce the difficulty and improve the stability. The effect of sealing and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Figure 5 Shown:

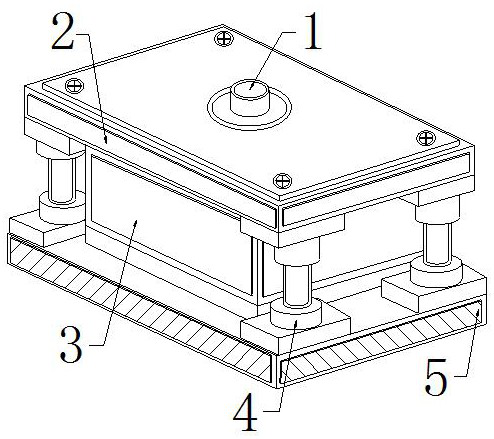

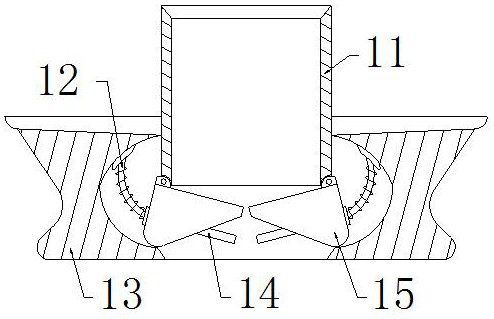

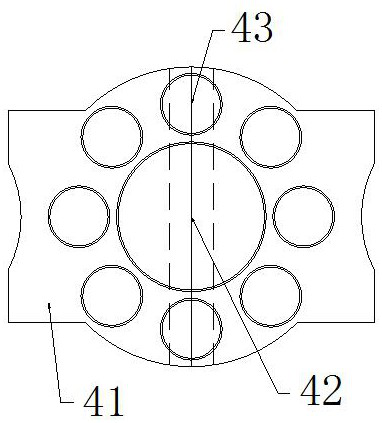

[0030] The invention provides an injection mold with a cooling function, the structure of which includes an injection port 1, an upper mold base 2, a cooling plate 3, a guide post 4, and a lower mold base 5, and the injection port 1 is installed in the middle of the upper mold base 2 , the cooling plate 3 is installed between the upper mold base 2 and the lower mold base 5, the guide post 4 is embedded between the upper mold base 2 and the lower mold base 5, and the injection port 1 is provided with a guide wall 11 , push bar 12, base 13, sealing layer 14, opening and closing plate 15, described guide wall 11 is installed in the middle of injection molding port 1, and described pushing bar 12 is embedded between base 13 and opening and closing plate 15, and described sealing layer 14 is embedded and connected with the opening and closing block 15, and the opening and closing plate 15 is hinged on both sides of the bott...

Embodiment 2

[0038] as attached Figure 7 to attach Figure 8 Shown:

[0039] The present invention provides an injection mold with a cooling function. The opening and closing plate 15 is provided with a hinge block 51, a rubber block 52, a gravity ball 53, and a weight plate 54. The hinge block 51 is embedded and fixed on the top of the left end of the opening and closing block 15. The rubber block 52 is installed on the right end of the opening and closing plate 15, the gravity ball 53 is matched with the internal clearance of the opening and closing plate 15, the weight plate 54 is embedded and connected with the opening and closing plate 15, and the rubber block 52 can be pressed after being squeezed. It fits tightly therebetween, and the gravity ball 53 faces down all the time due to gravity, and can roll inside it with the swing of the opening and closing plate 15. When the opening and closing plate 15 is opened, the gravity ball 53 makes its fixed position not Easy to close, if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com