A kind of tnt automatic transfer feeding device

A feeding device and automatic technology, applied in transportation and packaging, vibrating conveyors, conveyor objects, etc., can solve the problems of inability to guarantee TNT production requirements, difficulty in meeting explosion-proof requirements, and high labor intensity of workers. The effect of reducing the hidden danger of operation safety and preventing material splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

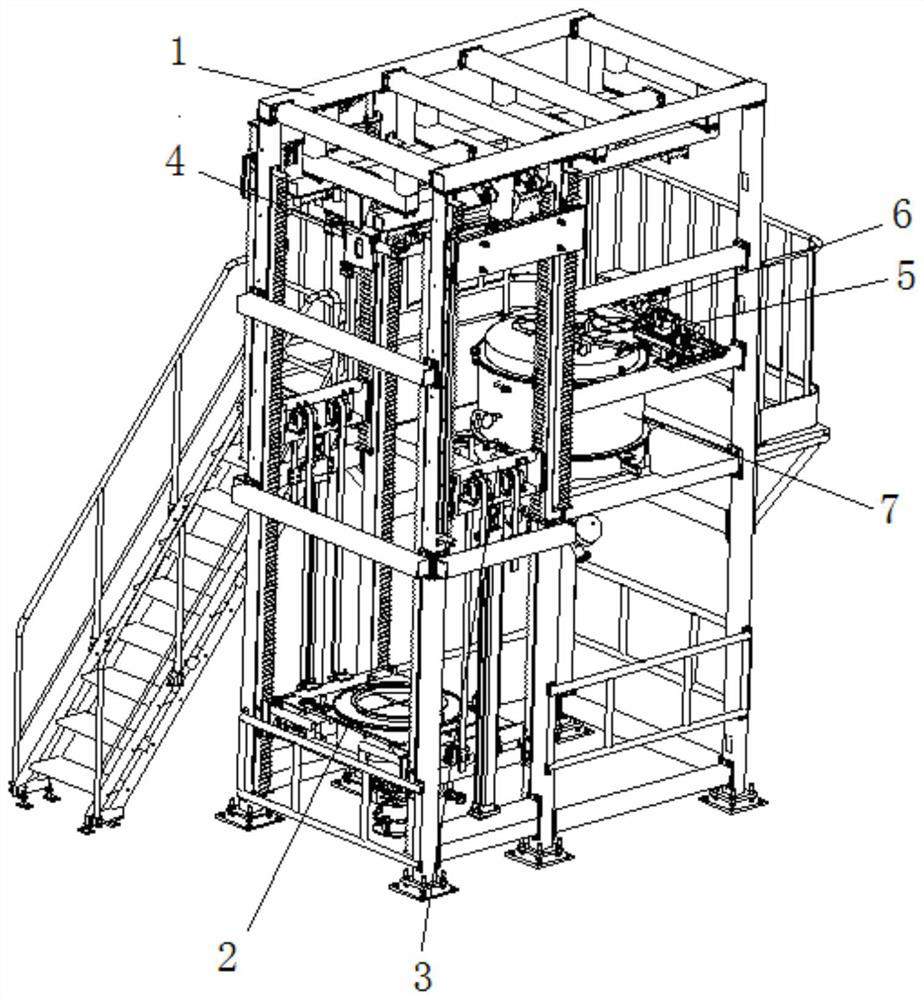

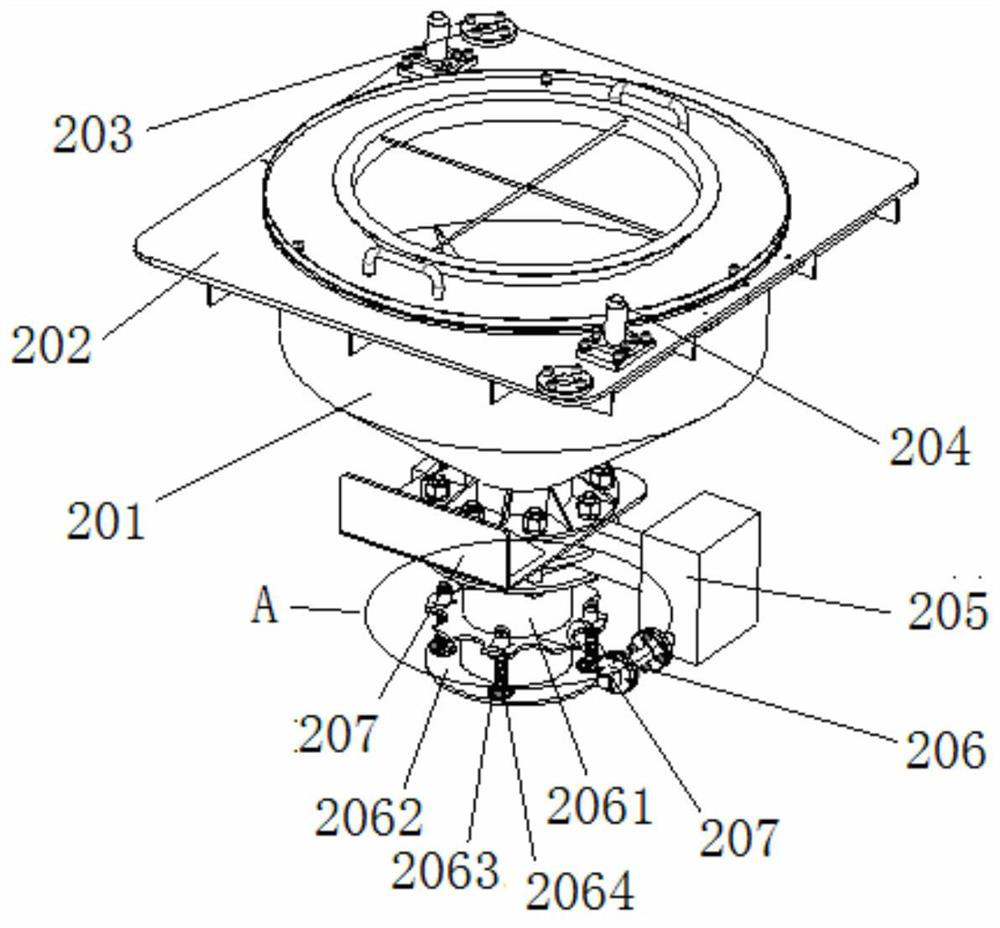

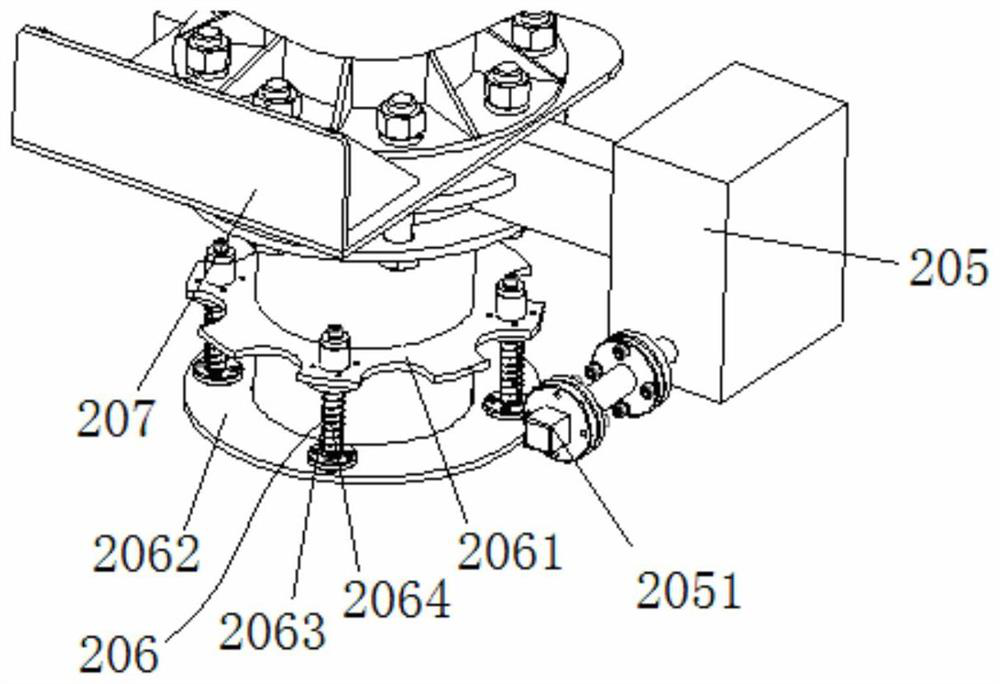

[0034] like Figure 1-11 As shown, the present invention includes equipment frame 1, TNT hopper unit 2, hopper lifting unit 3, grabbing traverse unit 4, valve opening and closing unit 5, TNT vibrating material unit 6 and TNT melter 7, wherein TNT hopper unit 2, The hopper lifting unit 3 , the grasping and traversing unit 4 , the valve opening and closing unit 5 , the TNT vibrating unit 6 and the TNT melter 7 are all arranged in the equipment frame 1 . like Figure 2~3 As shown, the TNT hopper unit 2 is provided with a hopper body 201, and the lower end of the hopper body 201 is provided with a vibration plate 207, a control valve 205 and a flexible docking assembly 206, and the TNT hopper unit 2 is driven up and down by the hopper lifting unit 3, And after the TNT hopper unit 2 is lifted in place, it is grasped and driven to the top of the TNT melter 7 by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com