Denitrification reactor and sewage treatment system

A reactor and denitrification technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of high energy consumption, achieve less sludge production, Avoid head loss and reduce power consumption

Pending Publication Date: 2021-06-29

北控水务(中国)投资有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a denitrification reactor and a sewage treatment system to solve the technical problems of the denitrification process existing in the prior art that need to add a carbon source when the carbon-nitrogen ratio of the influent is low and the energy consumption is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0043] This embodiment provides a sewage treatment system, including the denitrification reactor described in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

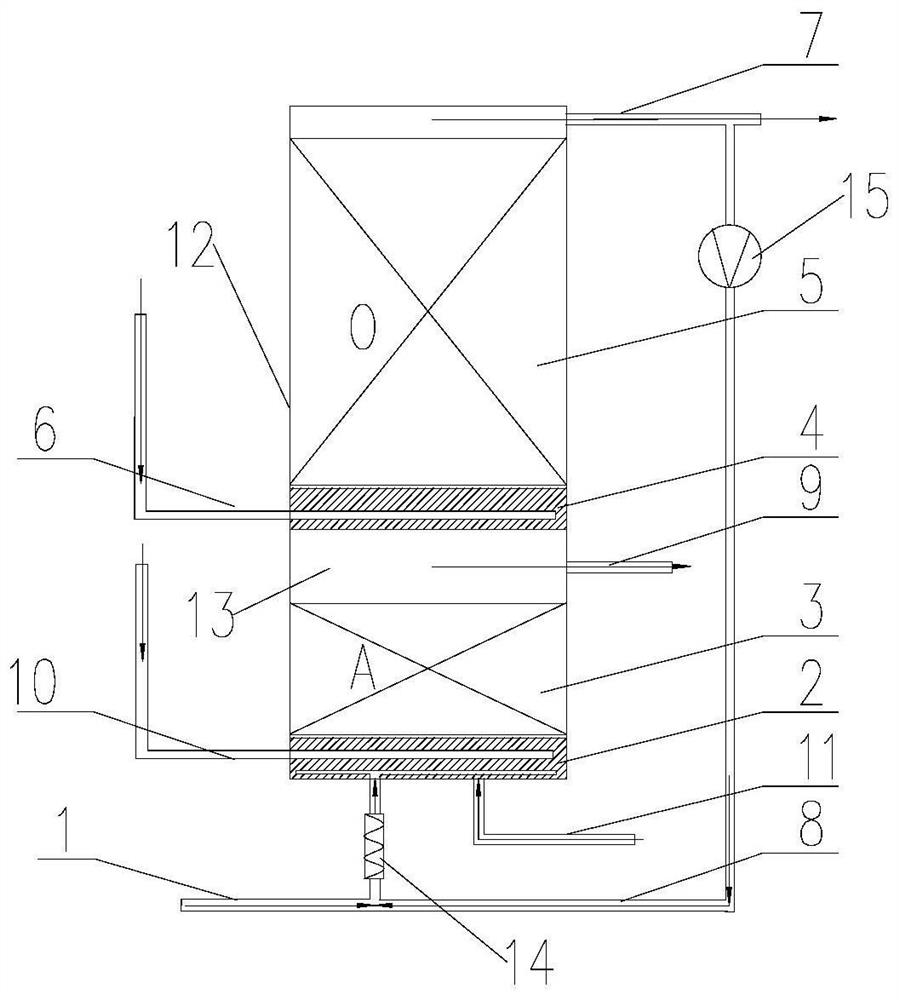

The invention provides a denitrification reactor and a sewage treatment system, relates to the technical field of sewage treatment equipment, and solves the technical problem of high energy consumption caused by the fact that a carbon source needs to be added when the carbon-nitrogen ratio of inlet water is small in an existing denitrification process. The device comprises a reactor body, an anoxic section and an aerobic section are sequentially arranged in the reactor body from bottom to top, the anoxic section is filled with an autotrophic denitrification filter material, and the aerobic section is arranged above the anoxic section and used for enabling sewage reacted with the autotrophic denitrification filter material in the anoxic section to rise to the aerobic section for biological contact oxidation reaction. According to the invention, the sewage and the autotrophic denitrification filter material are subjected to an autotrophic denitrification nitrogen removal reaction in the anoxic section, no additional carbon source needs to be added, the sludge generation amount is small, and the system is especially suitable for nitrogen removal of wastewater with a low carbon-nitrogen ratio. And then the sewage rises to the aerobic section for biological contact oxidation reaction, head loss is avoided, and the aerobic section does not need backwashing, so that the power loss is low, the sludge generation amount is small, and the system is suitable for low-carbon sewage treatment.

Description

technical field [0001] The invention relates to the technical field of sewage treatment equipment, in particular to a denitrification reactor and a sewage treatment system. Background technique [0002] The commonly used denitrification process in the field of water treatment is biological denitrification. Biological denitrification can be divided into heterotrophic denitrification and autotrophic denitrification. , reducing nitrate nitrogen to nitrogen gas. The traditional three-stage, two-stage and single-stage heterotrophic biological denitrification systems all need to add carbon sources to ensure the denitrification effect. For this reason, the pre-denitrification A / O process came into being, which can use the organic matter in the sewage itself to denitrify nitrification. At present, the common denitrification process includes denitrification process in the form of activated sludge method (A / O), denitrification aerated biological filter in the form of biofilm method ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/30

CPCC02F3/301C02F3/302

Inventor 李鑫玮王承亮刘永杰张黎明王俊安杭世珺

Owner 北控水务(中国)投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com