Advanced treatment method for cyanide and fluoride composite polluted wastewater

A complex pollution and advanced treatment technology, applied in water/sewage treatment, special compound water treatment, water/sewage multi-stage treatment, etc. Sludge production, sludge reduction, and residual reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation of modified chitosan: Dissolve chitosan in 1% acetic acid solution to obtain 2wt% chitosan solution, stir for 12-15h, add 0.05g / ml ammonium persulfate solution of 0.001 times the mass of chitosan , and then drop polydimethyldiallylammonium chloride equal to chitosan quality at a rate of 1d / s, and stir for 24-30h. After the reaction is completed, the reactant is dialyzed with distilled water for 24h, and then carried out with anhydrous acetone. Precipitate, and then centrifuge to obtain the precipitate and soak it in absolute ethanol for 5 minutes, filter and dry to obtain modified chitosan.

[0046] Coating: Dissolve n-tetrabutyl titanate in absolute ethanol, stir and mix evenly, then add tetraethyl orthosilicate dropwise at a speed of 30-35d / min, in which absolute ethanol, n-tetrabutyl titanate, orthosilicon The molar ratio of ethyl acetate is 6:3:1. After the dropwise addition, stir at a speed of 800-850rpm for 1 hour to obtain solution A; add hexadecylpyr...

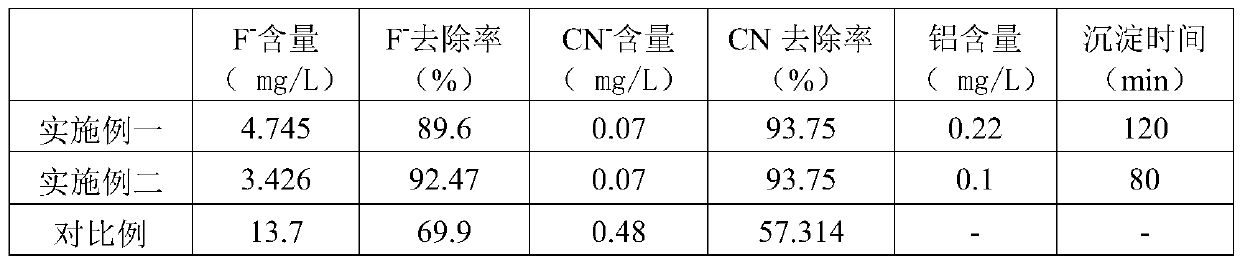

Embodiment 1

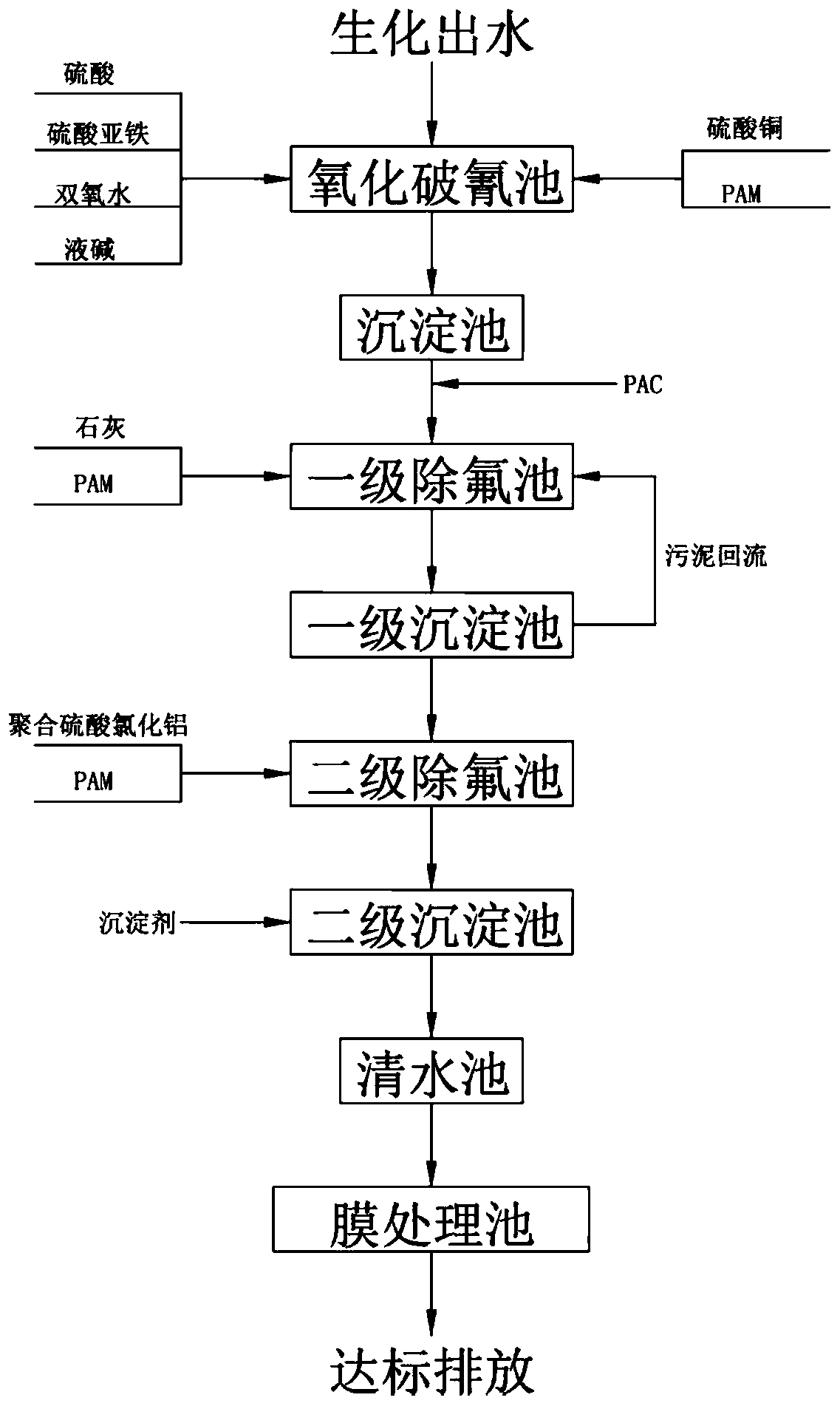

[0050] The present invention is a method for advanced treatment of cyanofluorine compound polluted wastewater. The specific treatment steps for treating cyanofluorine compound polluted wastewater are as follows:

[0051] 1) Put the biochemically treated waste water into the oxidative cyanide breaking tank, add sulfuric acid to adjust the pH value to 4.5-5, the sulfuric acid can be used with any concentration of sulfuric acid, and in this embodiment, the concentrated sulfuric acid with a concentration of 98% is selected for pH adjustment. Then according to 1700-1750mg / L, this embodiment chooses to add ferrous sulfate with a feed rate of 1700mg / L, after stirring for 15-18min, according to 500-550mg / L, this embodiment chooses to add hydrogen peroxide with a feed rate of 500mg / L , according to 100-120mg / L, preferably 100mg / L, add copper sulfate, continue to stir and react for 2-2.5h, add liquid caustic soda to adjust the pH value to 6.5-7, and finally according to 1-3mg / L, this emb...

Embodiment 2

[0058] Compared with implementation one, this embodiment is different in that in step 6) of this embodiment, after the wastewater in the secondary defluoridation tank is poured into the secondary sedimentation tank, according to 2-5mg / L, this implementation For example, choose to add the precipitating agent at the dosage of 3mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com