Semi-automatic flame edge banding machine

A semi-automatic, edge-banding machine technology, applied to tools for roofing, roofing, construction, etc., can solve problems such as low work efficiency, limited air pipe length, hidden dangers, etc., to improve efficiency and safety, improve laying efficiency, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

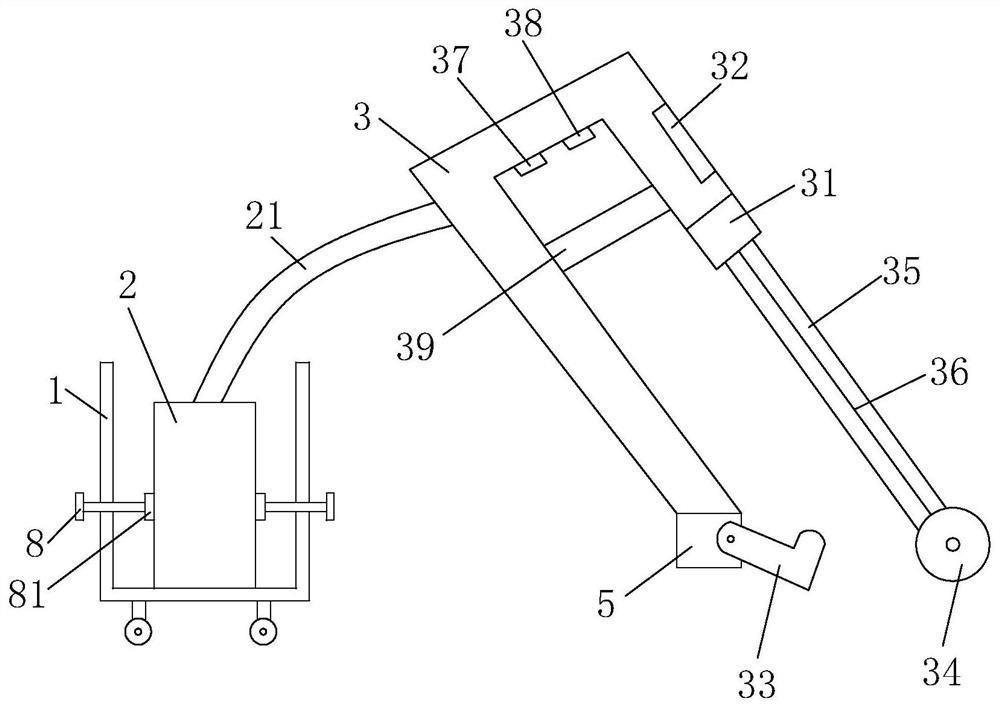

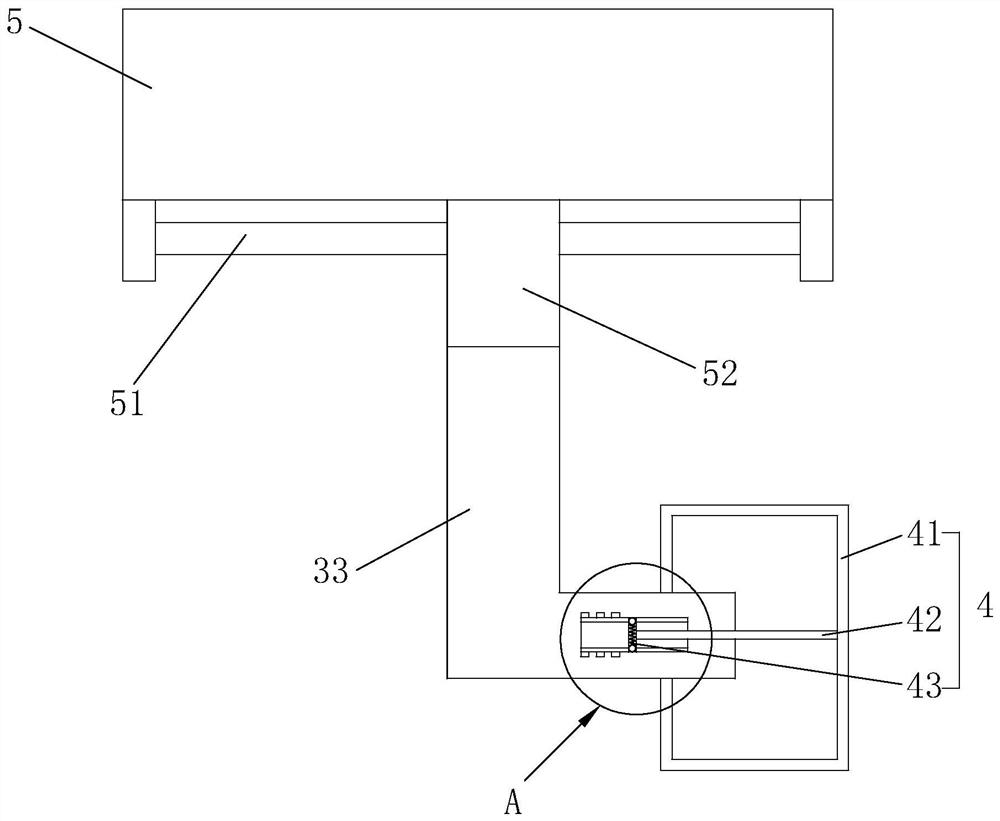

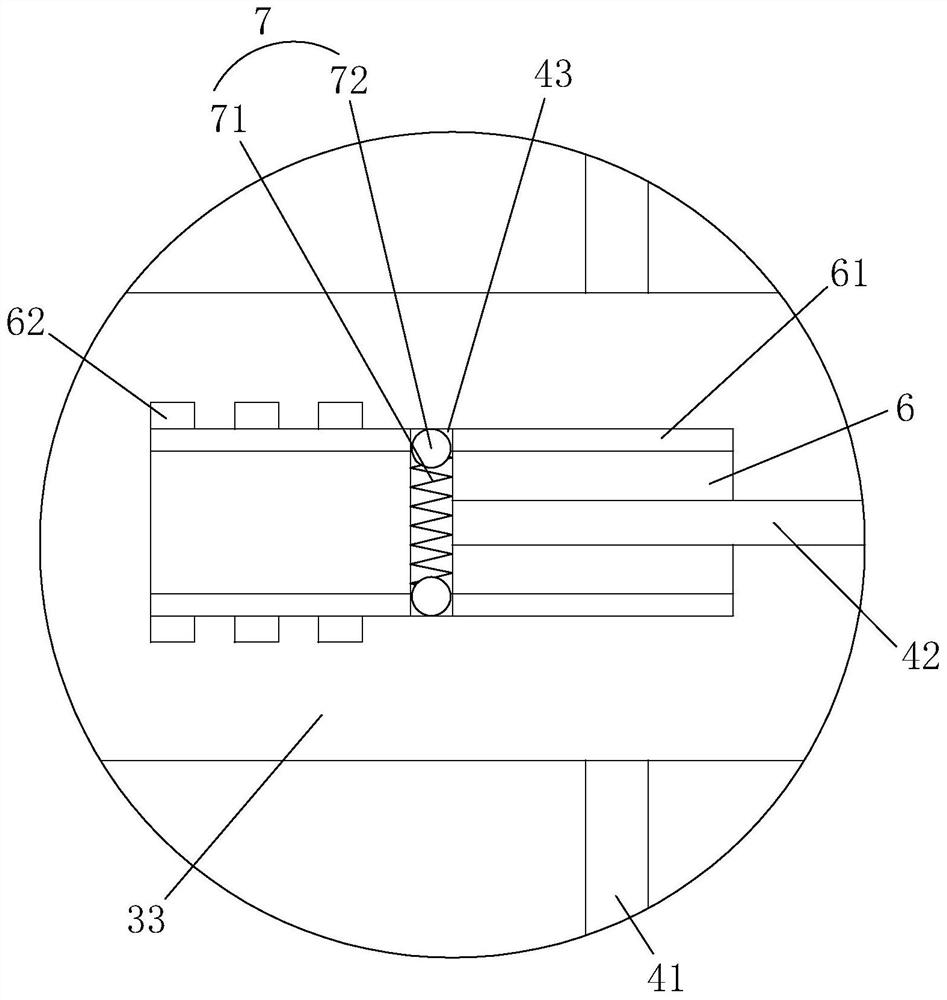

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] refer to figure 1, is a semi-automatic flame edge banding machine disclosed by the present invention, including a movable support 1, an anti-tempering valve, a gas tank 2 and a hand-held pneumatic walking flame gun 3, the gas tank 2 is detachably fixed in the bracket 1, and the gas tank 2 passes through Trachea 21 and backfire prevention valve are connected with hand-held pneumatic walking flame gun 3. The hand-held pneumatic walking flame gun 3 is provided with a flame controller, an air inlet pipe, an air outlet pipe, a drive motor 31 and a power module 32, the power module 32 is electrically connected to the drive motor 31 and the flame controller respectively, and the drive motor 31 is connected to the flame control One end of the hand-held pneumatic walking flame gun 3 is equipped with a flame nozzle 33 connected to the air pipe 21, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com