Using method of crawler-type operation platform for net rack construction

An operating platform and crawler-type technology, which is applied to the attachment of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problems of machinery such as wheeled lift trucks, the difficulty of erecting scaffolding and platforms, and the impact on the progress of the floor construction. and other problems, to achieve the effect of light weight, flexible use and less input materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

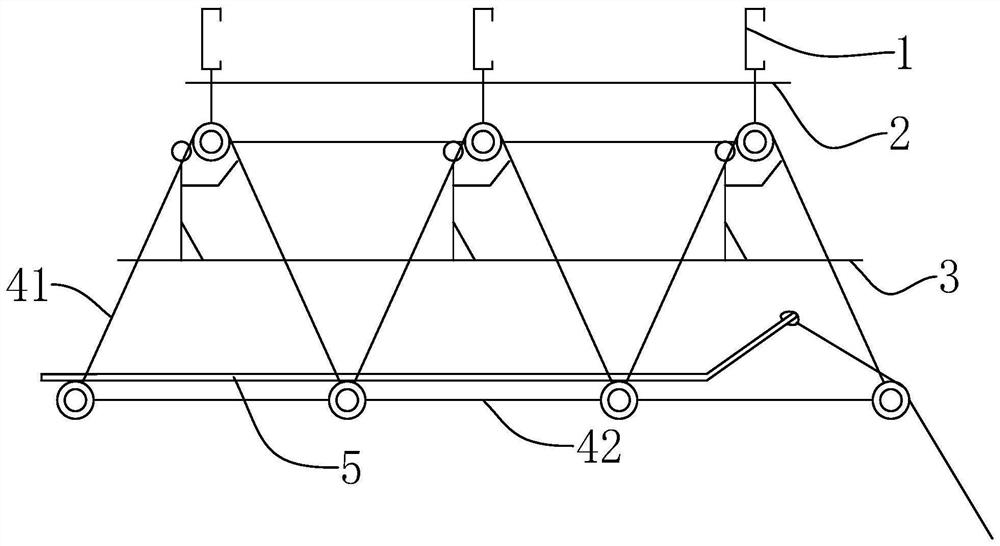

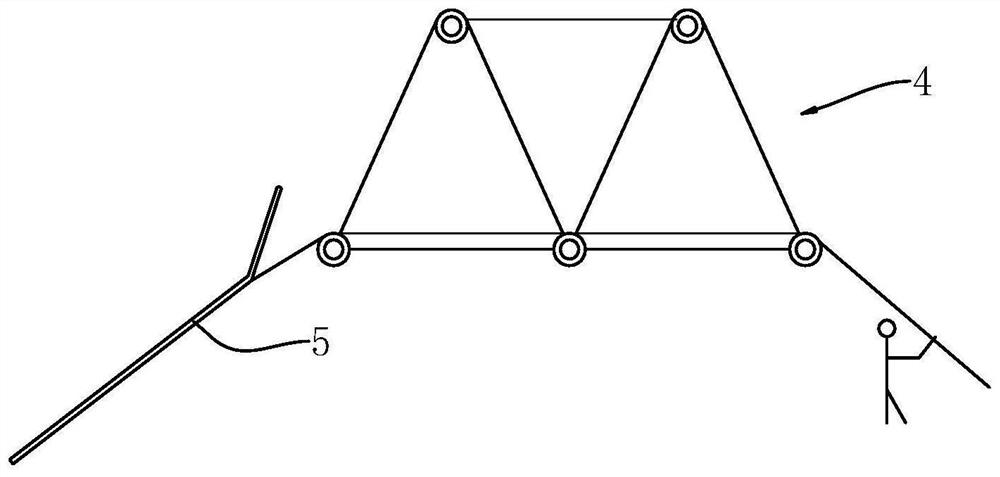

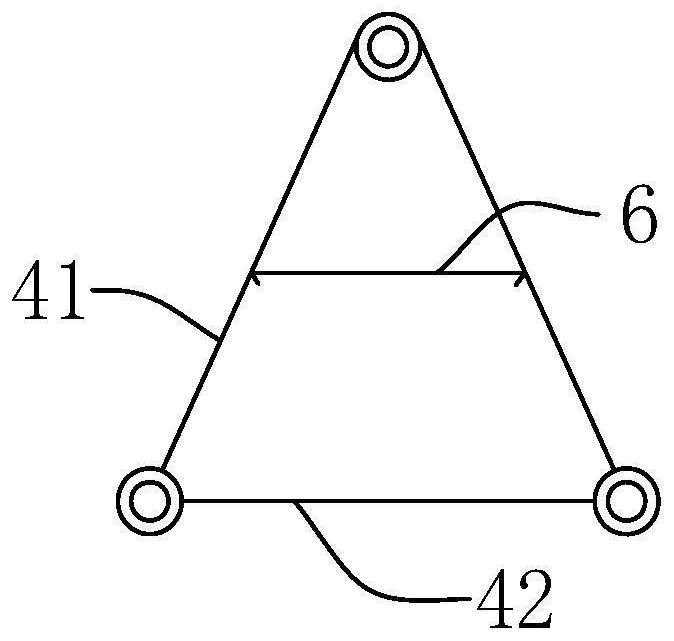

[0026] Such as figure 1 As shown, the crawler-type operating platform for network frame construction of the present invention first needs to set up a turnable and movable platform on the lower chord of the network frame as a primary platform, which can meet the needs of providing a construction work surface for the construction of the secondary platform 3; The rod 41 is for supporting and setting up the secondary operating platform, and the inner panel 2 is installed and constructed on the secondary platform 3, and the primary platform and the secondary platform 3 are gradually pushed forward with the construction progress. Wherein, the front refers to the direction before the construction.

[0027] Take the following structure as an example. The grid structure is a square pyramid placed obliquely. The single grid is 4 meters * 4 meters. The center elevation of the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com