Cooking fume separation and purification all-in-one machine

A technology of oil fume separation and integrated machine, which is applied in the field of kitchen appliances, can solve the problems of poor separation effect of range hoods, pollute the atmosphere and kitchen air, etc., achieve the effect of simple structure, ensure air quality, and improve purification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

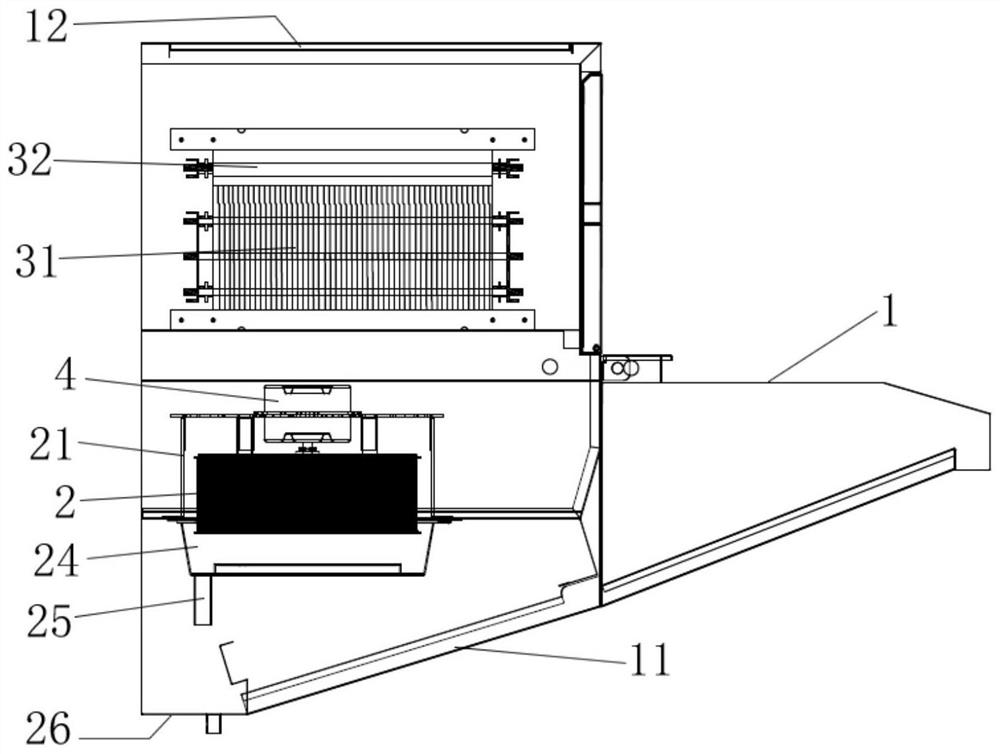

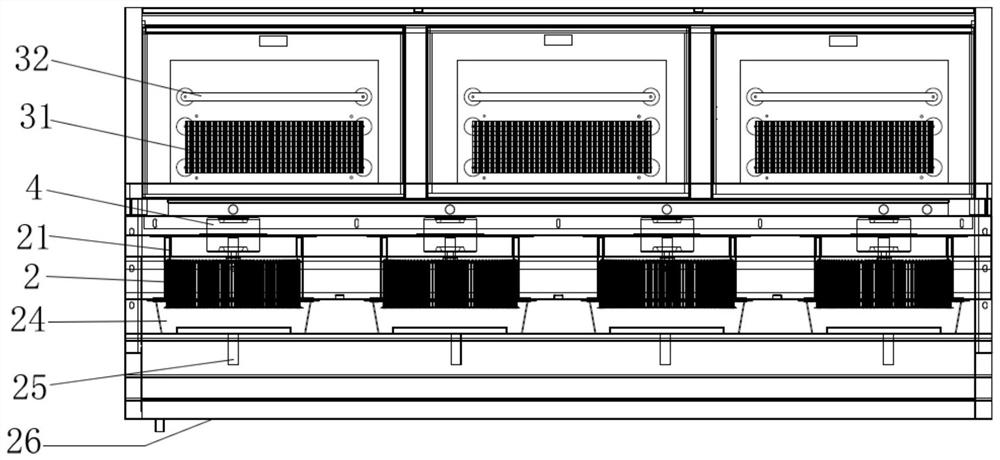

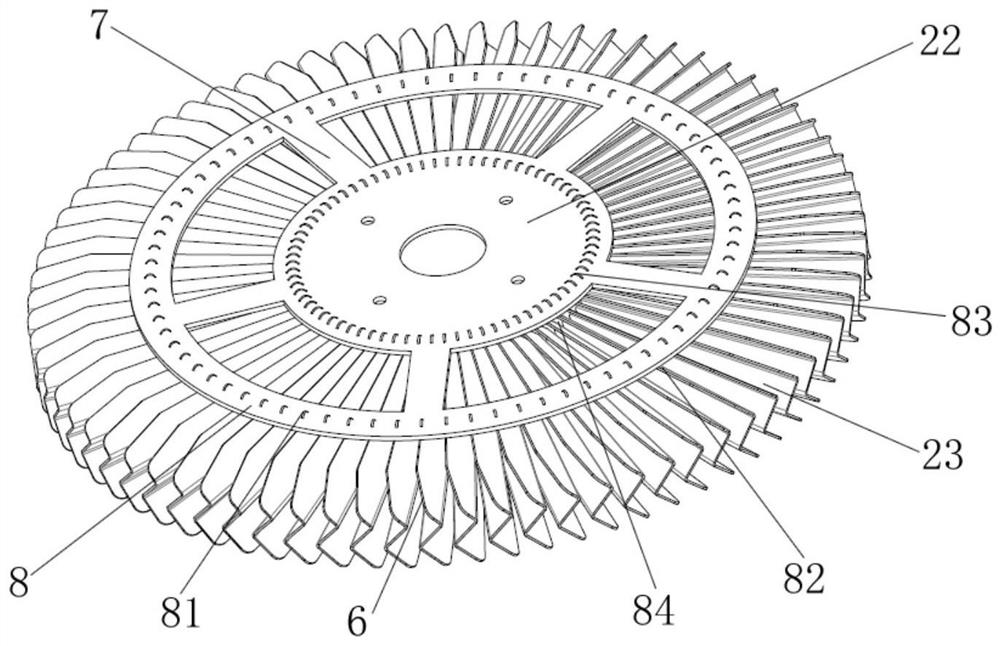

[0029] The structural schematic diagram of an integrated machine for oil fume separation and purification in this embodiment is as follows: Figure 1 to Figure 5 As shown, it includes a fume hood 1, a fume separation disc 2 and a waste gas treatment device inside it; the fume inlet 11 and the fume outlet 12 are respectively provided at both ends of the fume hood 1, and the fume outlet 12 communicates with the air duct; the fume separation The disk 2 includes fan blades, rotating shaft, motor 4 and bracket 21 connected in sequence, and the fan blades are arranged at the oil fume inlet 11; And / or the UV purification lamp 32 on the top.

[0030] In this embodiment, the oil fume enters from the oil fume inlet 11, and the treated gas is discharged from the oil fume outlet 12 through the air duct. The oil fume separation plate 2 is set to suck and separate the oil fume generated by cooking, and then the oil fume separation plate 2 The separated waste gas is filtered and decomposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com