Fault detection method for train bearing box

A technology for fault detection and bearing boxes, applied in railway vehicle testing, testing of mechanical components, testing of machine/structural components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

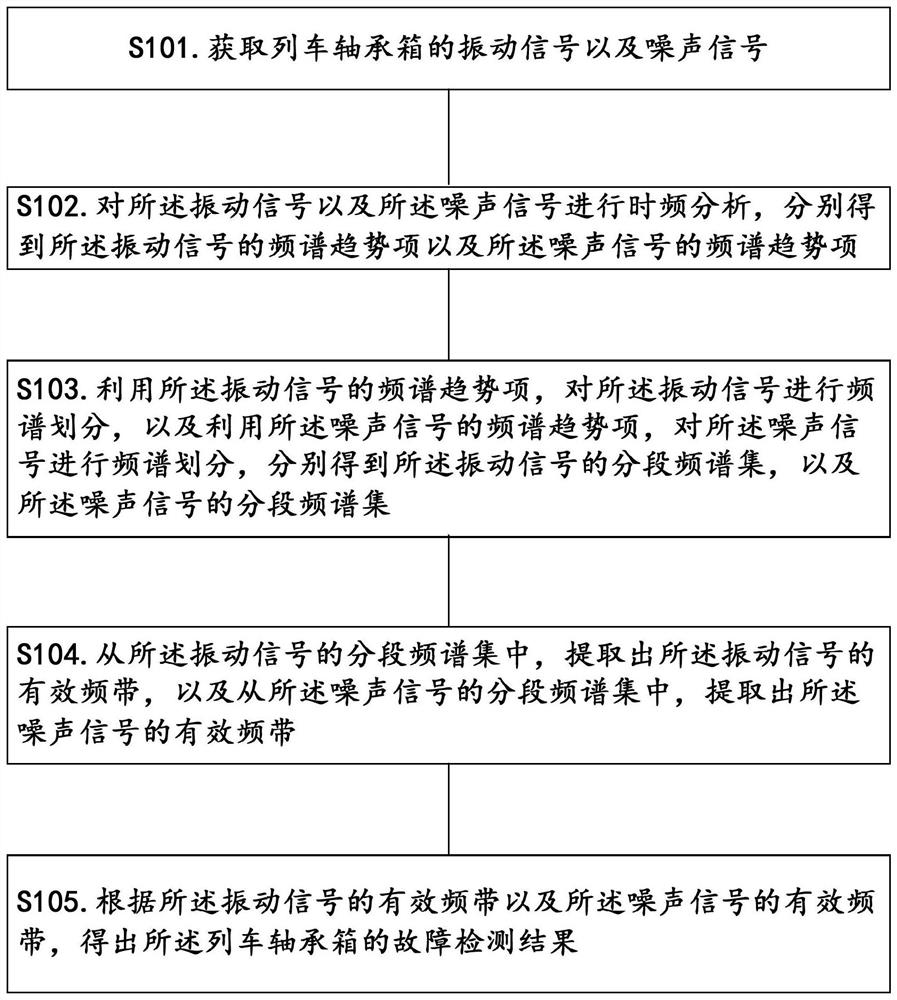

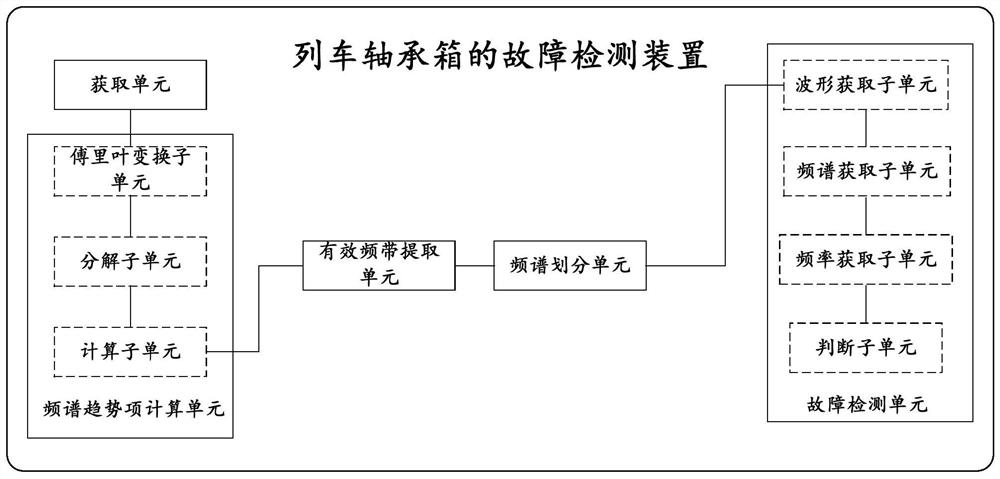

[0148] Such as figure 1 As shown, the fault detection method of the train bearing box provided in the first aspect of this embodiment is applicable to the fault detection of the train bearing box. In this embodiment, the vibration signal and the noise signal of the bearing box are analyzed in time domain and divided into frequency spectrum, Furthermore, the effective frequency band of the vibration signal and the noise signal can be extracted; finally, the fault detection of the bearing box can be realized according to the effective frequency band; the detection method provided in this embodiment can realize the fault detection of the bearing box based on the status data of the bearing box, and the detection High precision and accuracy can greatly improve the safety of train operation.

[0149] The fault detection method for the train bearing box provided in this embodiment may, but is not limited to, include the following steps S101-S105.

[0150] S101. Obtain vibration sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com