Simple sample preparation method for testing drawing behavior of fibers in cement matrix

A fiber and matrix technology, applied in the field of characterization of building materials, can solve the problems of complex sample preparation, incompatibility of different types of fibers, and inability to ensure accurate embedding depth, etc., and achieve the goal of simple sample preparation, easy operation, and improved use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

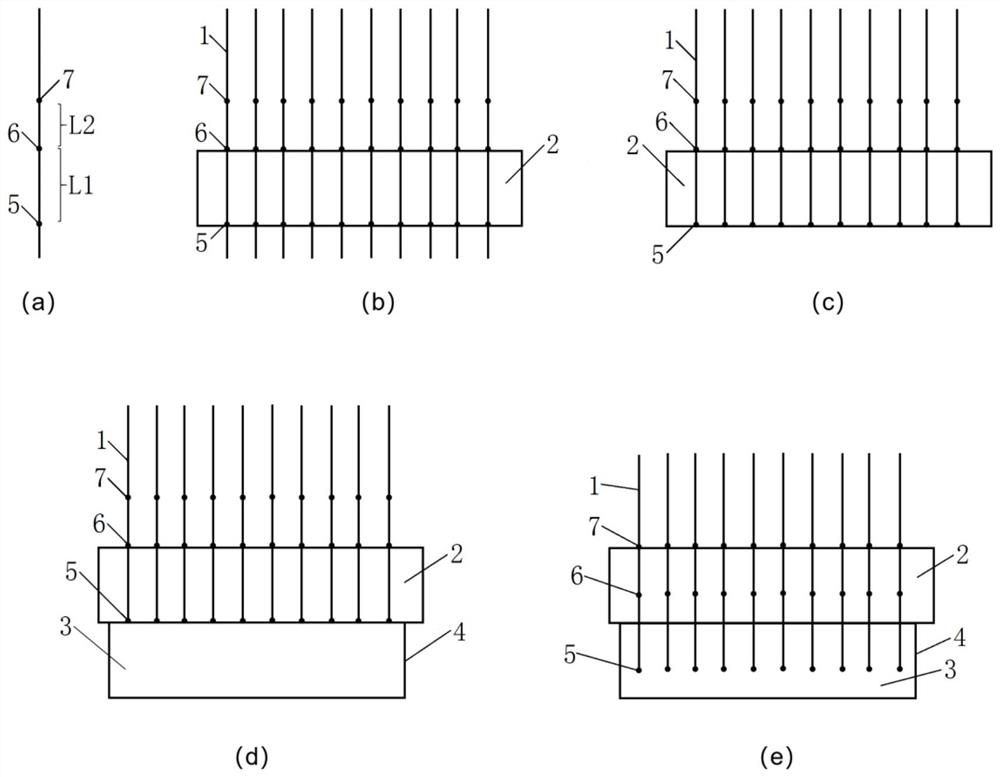

[0026] A kind of simple and easy sample preparation method of test fiber pulling behavior in cement matrix comprises the steps: the fiber used in the present embodiment is sisal fiber, and the porous elastic material that uses is the thick sponge of 3cm; Namely mark point-5 to The distance L1 between the mark points 2 and 6 is 3cm; the depth L2 that the sisal fiber is inserted in the mortar is set to be 2cm;

[0027] (1) The sisal fiber 1 is cut to 10cm, and then the two ends are clamped and straightened with clips. After straightening, three mark points are successively set on the sisal fiber 1, namely mark point one 5 and mark point two 6 and mark point three 7; such as figure 1 as shown in (a);

[0028] (2) Utilize a thin needle to pass the sisal fiber 1 vertically through the porous elastic material (sponge) 2 with a thickness of 3 cm, and wear 10 sisal fibers 1 on each sponge 2, and make the marking points set on it One 5 and mark point two 6 are respectively flat with ...

Embodiment 2

[0034] A kind of simple and easy sample preparation method of test fiber pulling behavior in cement matrix, comprises the steps: the fiber used in the present embodiment is sisal fiber, and the porous elastic material that uses is the thick sponge of 2cm; Namely mark point-5 to The distance L1 between the mark points 2 and 6 is 2cm; the depth L2 that the sisal fiber is inserted in the mortar is set to be 1cm;

[0035] (1) The sisal fiber 1 is cut to 5cm, and then the two ends are clamped and straightened with clips. After straightening, three mark points are successively set on the sisal fiber 1, namely mark point one 5 and mark point two 6 and mark point three 7;

[0036] (2) Utilize a thin needle to pass the sisal fiber 1 vertically through the porous elastic material (sponge) 2 with a thickness of 2cm, and wear 10 sisal fibers 1 on each sponge 2, and make the marking points set on it The first 5 and the second mark 6 are respectively flat with the two sides of the sponge 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com