A Scanning Electron Microscope Observation Method for Barium Titanate Ultrafine Powder

An electron microscope and barium titanate technology, which is applied in the field of instrument analysis, can solve the problems of blurred pictures, uneven dispersion, and difficulty in observing the whole picture of particles, so as to achieve a simple sample preparation method, good repeatability, and avoid powder dispersion. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

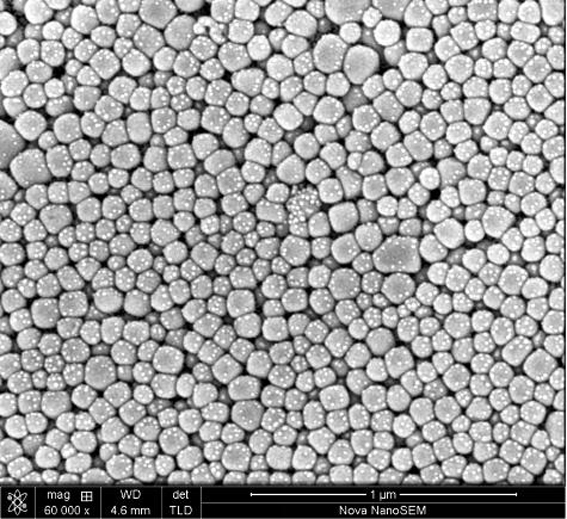

[0024] 1) Put 0.1 g of barium titanate ultrafine powder with a particle size of 80-120 nm (cubic phase nanoscale) prepared by the hydrothermal method in a beaker, add 60 ml of absolute ethanol solution, and place in an ultrasonic oscillator After oscillating ultrasonically at 60HZ for 15 minutes, shake well to obtain a turbid liquid of barium titanate ultrafine powder;

[0025] 2) Use a clean straw to suck out 1ml of barium titanate ultrafine powder turbid liquid and spread it evenly on the conductive adhesive;

[0026] 3) Put the conductive adhesive stained with the turbid liquid of barium titanate ultrafine powder in a vacuum dryer, and dry at 95°C for 30min at a vacuum of 0.5MPa;

[0027] 4) Place the dried conductive adhesive in step 3) in the center of the sample loading platform of the sample press, set the holding time for 10s, and the pressure is 1.0MPa;

[0028] 5) Blow off the floating particles on the edge of the pressed sample prepared in step 4), and place it in ...

Embodiment 2

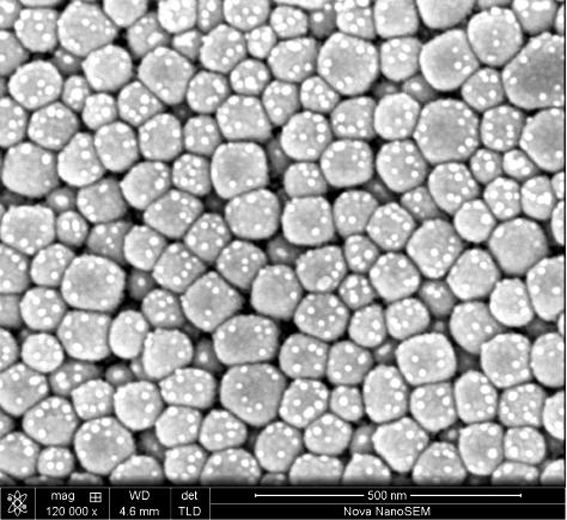

[0030] 1) Put 0.15 g of barium titanate ultrafine powder with a particle size of 300-500 nm (tetragonal phase nanoscale) prepared by the hydrothermal method into a test tube, add 0.02 g of sodium hexametaphosphate and 80 ml of absolute ethanol , in an ultrasonic oscillator at 50HZ ultrasonic oscillation for 20min and then shake well to obtain barium titanate ultrafine powder turbid liquid;

[0031] 2) Suck out 1ml barium titanate ultrafine powder turbid liquid with a clean straw and spread it evenly on the silicon wafer;

[0032] 3) Place the silicon wafer with the turbid solution of barium titanate ultrafine powder in a vacuum dryer, and dry at 100°C for 30 minutes at a vacuum of 0.5 MPa;

[0033] 4) Place the dried silicon wafer in step 3) in the center of the sample loading platform of the sample press, set the holding time for 5s, and the pressure is 0.5MPa;

[0034] 5) Blow off the floating particles on the edge of the pressed sample prepared in step 4), and stick it on ...

Embodiment 3

[0036] 1) Put 0.2 g of ultrafine barium titanate powder with a particle size of 400-500 μm (tetragonal phase submicron order) obtained by calcining the cubic phase barium titanate powder prepared by the hydrothermal method into a beaker, and add 0.02 g Sodium hexametaphosphate and 100 ml of acetone solution were shaken in an ultrasonic oscillator at 70HZ for 30 minutes to obtain a barium titanate ultrafine powder turbid solution;

[0037] 2) Suck out 2 ml barium titanate ultrafine powder turbid liquid with a clean straw and spread it evenly on the silicon wafer;

[0038] 3) Place the silicon wafer with the turbid solution of barium titanate ultrafine powder in a vacuum dryer, and dry at 100°C for 30 minutes at a vacuum of 0.5 MPa;

[0039] 4) Place the dried silicon wafer in step 3) in the center of the sample loading platform of the sample press, set the holding time for 5s, and the pressure is 1.0MPa;

[0040] 5) Blow off the floating particles on the edge of the pressed sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com