Pneumatic oil nozzle

A technology of fuel injectors and nozzles, which is applied to fuel injection devices, and uses high-pressure gas to bring fuel into the engine and engine components. Effects of improved exhaust gas conditions, low cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

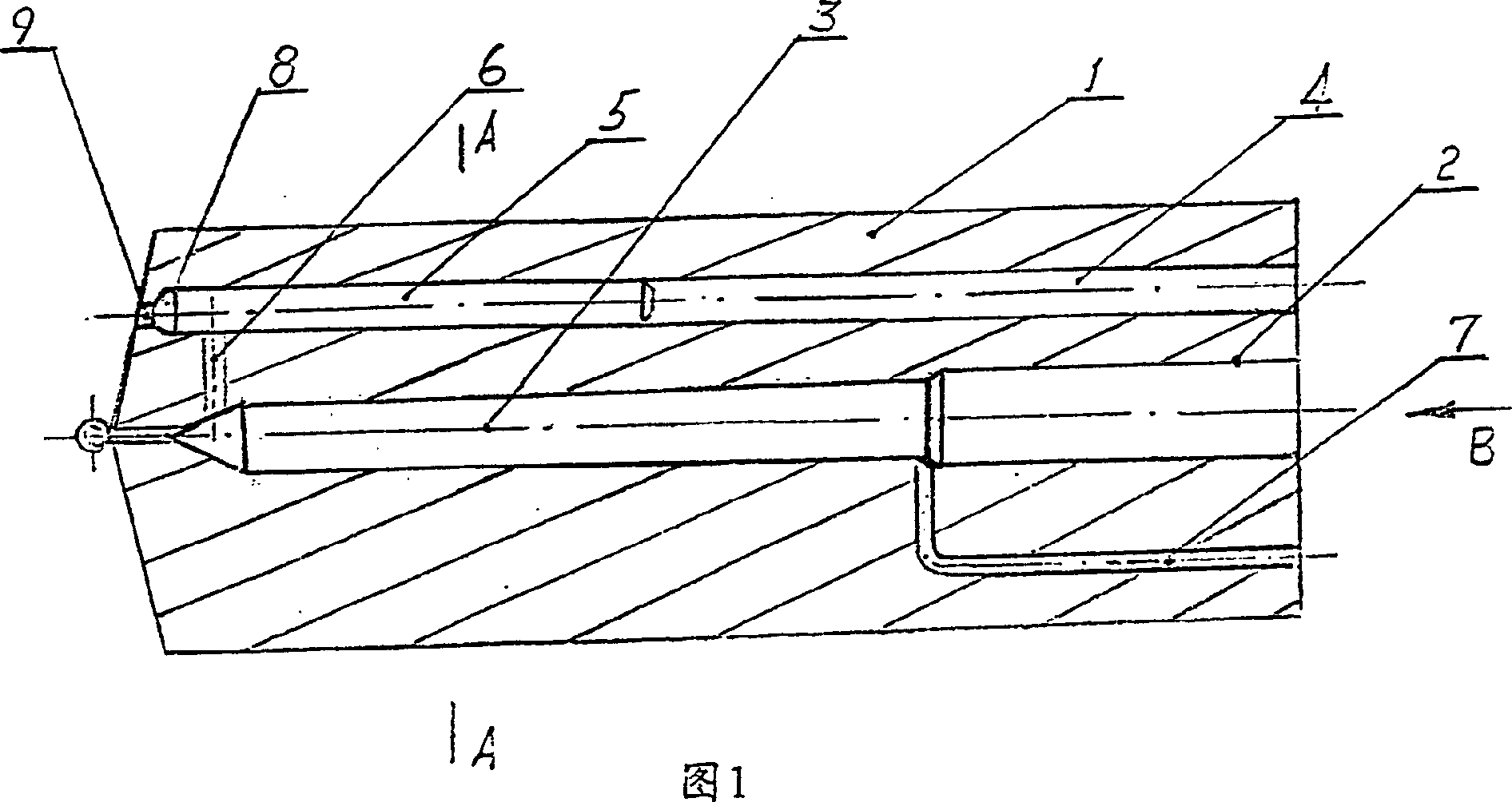

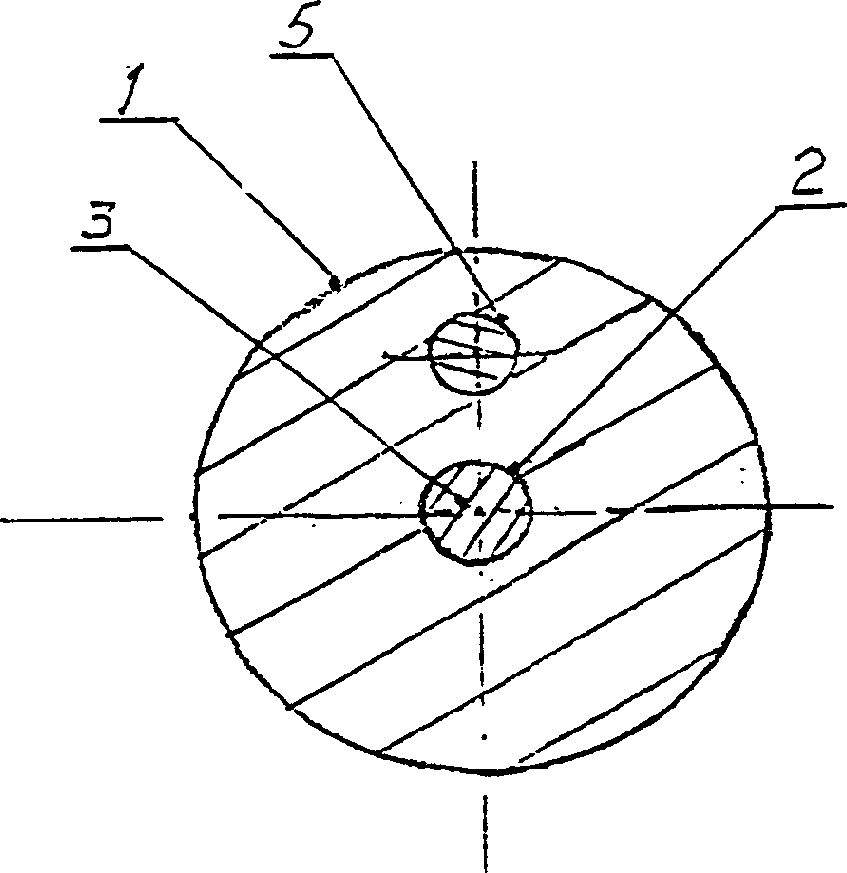

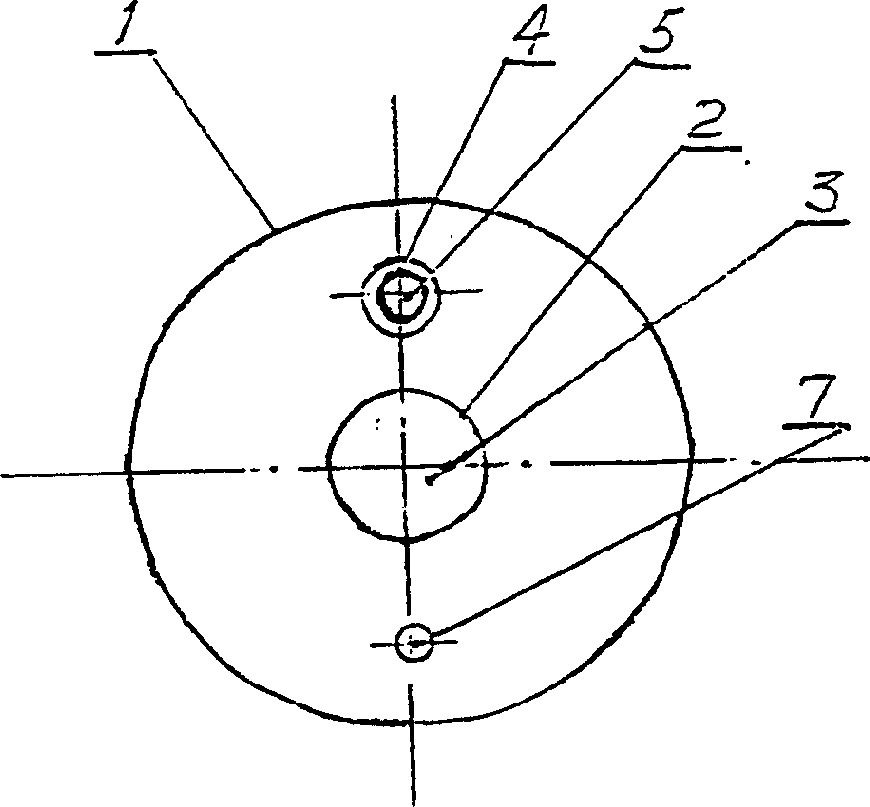

[0016] The nozzle body (1) of the entrainment injection nozzle is made with a middle through hole (2). The middle through hole (2) is a through hole, and its lower part is made with a needle valve hole. Mouth is contained in the cylinder, and needle valve core (3) is contained in the middle through hole (2), and the lower end valve head of needle valve core (3) cooperates with middle through hole (2) bottom needle valve hole to form needle valve. The upper part of the needle spool (3) and the middle through hole are an interference dynamic fit, and the lower part of the needle spool (3) and the middle and lower parts of the middle through hole (2) form an oil passage gap type dynamic fit. When the needle spool (3) moves up and the needle valve is opened, the lower part of the needle spool (3) and the middle and lower part of the middle through hole (2) form an oil passage gap. The oil passage gap communicates with the oil passage hole (7) made in the oil nozzle body (1). The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com