Method for calculating axial load bearing capacity of aircraft panel

A technology of aircraft siding and bearing capacity, applied in geometric CAD and other directions, can solve the problems of long cycle, difficult to meet the increasingly high requirements of aircraft design, difficult to meet the rapid iteration of aircraft design, etc., to achieve clear structural stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

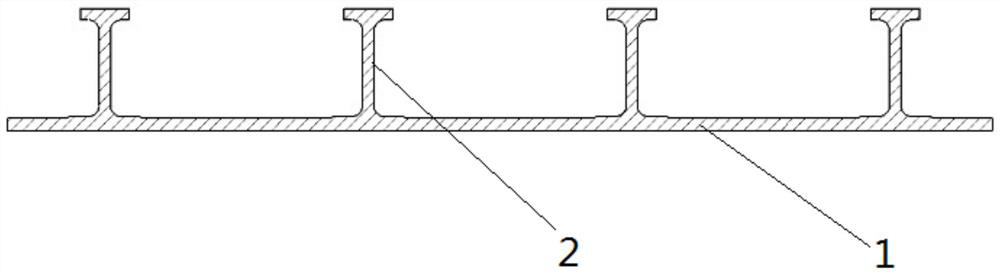

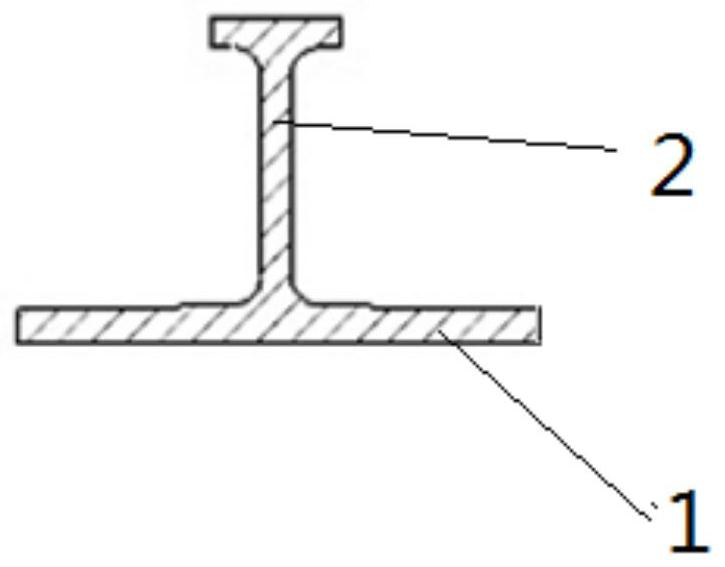

[0012] Referring to the accompanying drawings, the aircraft panel provided by the present application contains a skin 1 and a plurality of stringers 2, and the design parameters of the aircraft panel are known, for example: skin thickness δ sk , the width b of the skin between the stringers, the elastic modulus E of the skin material, the Poisson's ratio μ of the skin material, and the stringer section parameters and other design parameters.

[0013] The steps to calculate the axial load carrying capacity of aircraft panels are as follows:

[0014] 1) Taking each long stringer as the center, divide the aircraft panel into multiple calculation units;

[0015] Such as figure 1 As shown, the aircraft panel is composed of four long stringers and the skin, with each stringer as the center, the aircraft panel is divided into four calculation units; each calculation unit is as follows figure 2 shown. That is to say, the panel composed of long stringers and 1 / 2 long stringer spaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com