Anti-seismic contact box

A technology of contact box and anti-vibration plate, applied in anti-vibration equipment, shields/blinds to prevent contact with contacts, cooling/ventilation of substation/switchgear, etc., can solve problems such as temperature rise of contact box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments shown in the embodiments of the present application will be clearly and completely described below with reference to the drawings in the embodiments shown in the embodiments of the present application.

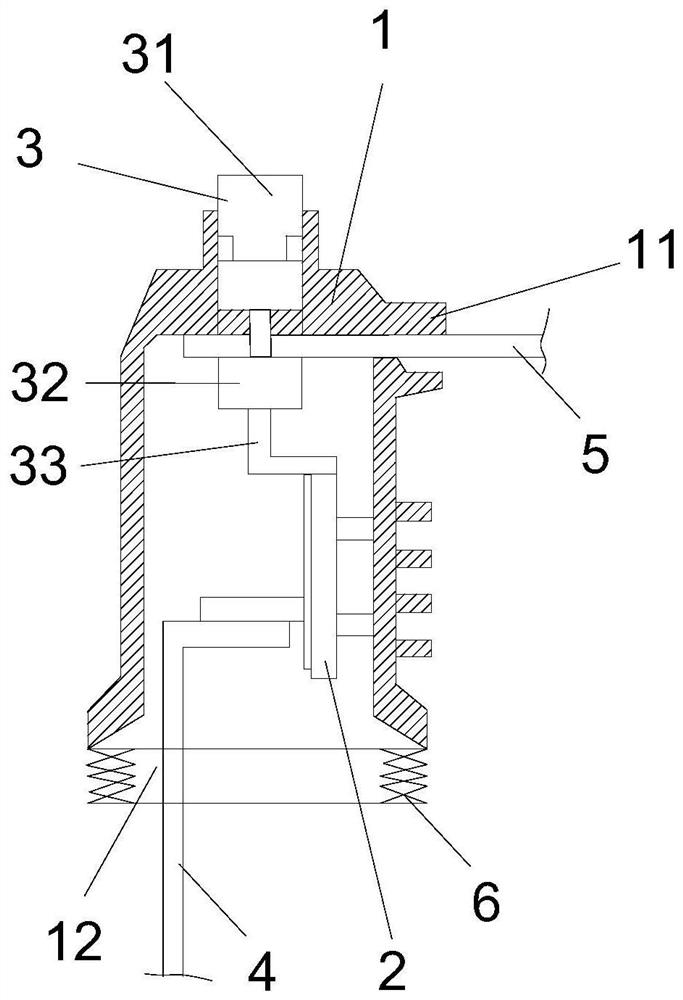

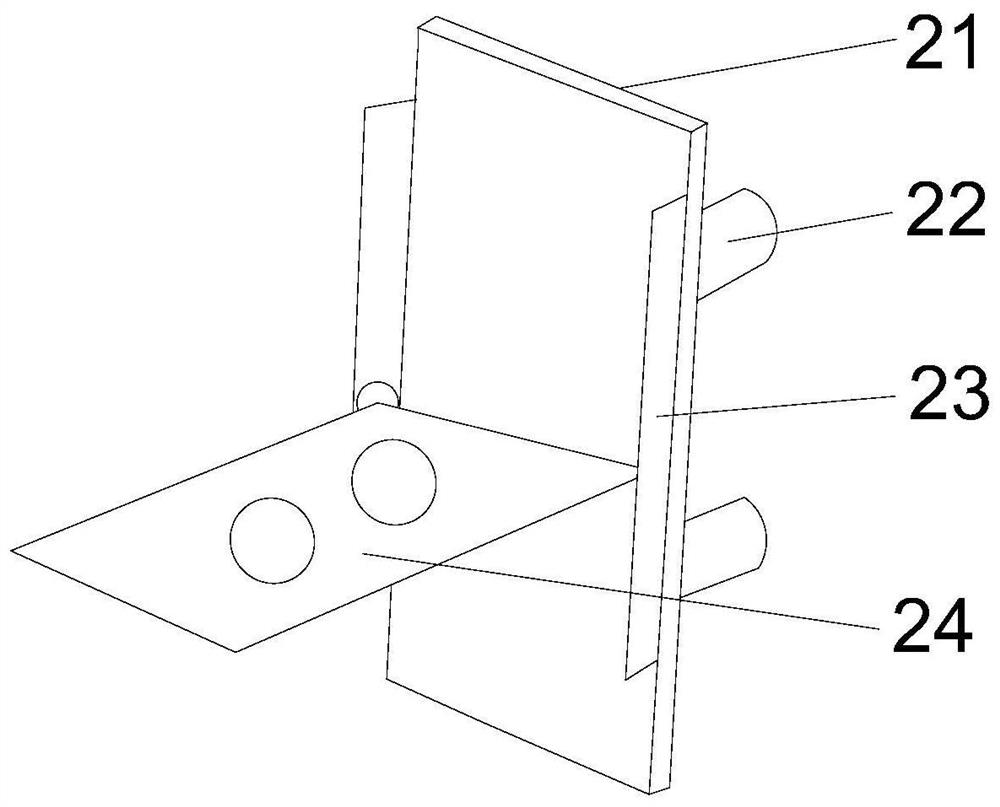

[0020] see Figure 1 to Figure 2 As shown in the schematic diagram, an anti-vibration contact box includes a housing 1, an anti-vibration plate 2, a static contact 3, a moving contact 4, and a bus bar 5; the anti-vibration plate 2 includes a connecting plate 21, a fixed column 22, a slide 23 and a sliding plate 24, the fixed column 22 is located on one side of the connecting plate 21, and the two slide grooves 23 are provided on both sides of the other side of the connecting plate 21, and one end of the sliding plate 24 is close to Along the connecting plate 21, the other end of the sliding plate 24 slides in the chute 23, and the sliding plate 24 is located between one side of the connecting plate 21 and the bottom edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com