Vertical cavity surface emitting laser and preparation method thereof

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers and other directions, can solve the problems of laser temperature rise, laser optical output power reduction, reduction and other problems, to achieve data transmission bandwidth and frequency increase, reduce Overall resistance value, the effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

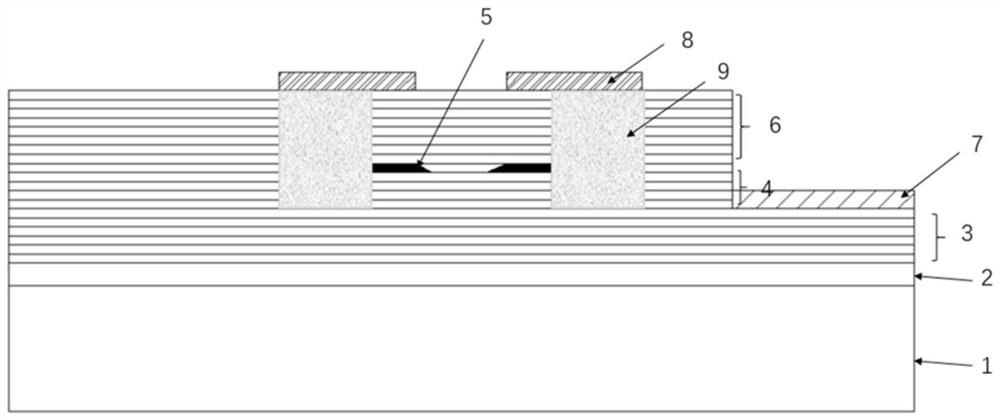

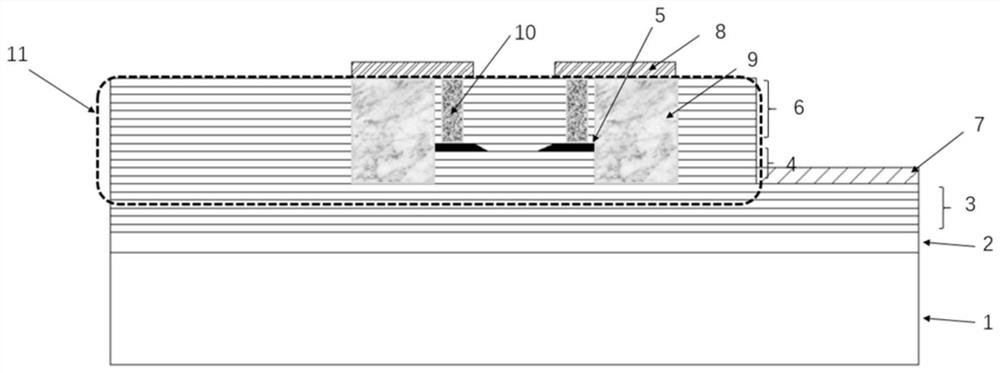

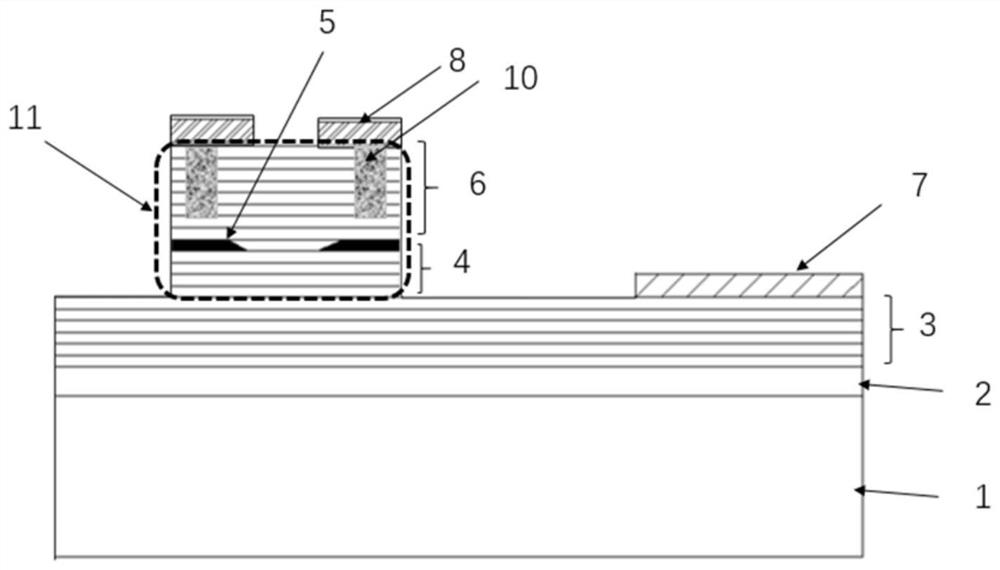

[0029] Aiming at the deficiencies of the existing oxidation-limited structure VCSEL, the solution of the present invention is to set an electrical channel composed of a conductive material between the P-type electrode and the oxidation-limited layer. On the one hand, the overall resistance value of the laser is reduced, and the electrical channel is formed The conductive material of the sexual channel can conduct the heat generated by the quantum well out of the laser more quickly, thereby effectively improving the temperature stability of the laser, and effectively solving the problem that the heat caused by the "self-heating" effect of the laser cannot be effectively dissipated and the laser can not be effectively dissipated. Due to the problem of temperature rise, the data transmission bandwidth and frequency of the laser have been improved; in addition, due to the electrical channel replacing part of the P-type DBR, the overall capacitance value of the P-type DBR has been ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com