Photocatalytic denitration testing system and using method thereof

A test system and photocatalytic technology, applied in the field of photocatalytic denitrification, can solve the problems of large land occupation, low denitrification activity, complex device structure and operation, etc., and achieve the effect of convenient operation process, simple device and stable gas path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

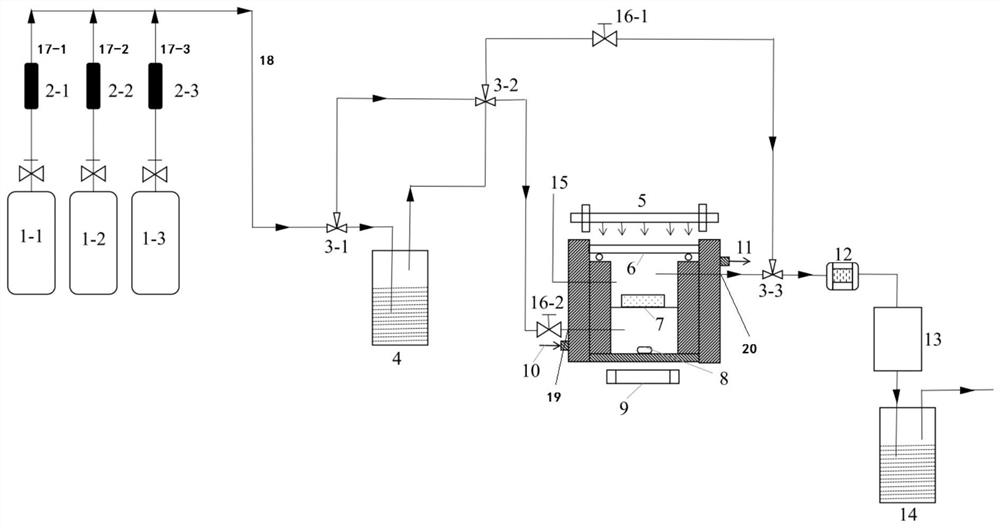

[0034] For the photocatalytic denitrification test, the gas used in the gas storage cylinder includes nitrogen 1-1, nitrogen monoxide 1-2, and oxygen 1-3. The three gases contained in the gas storage cylinder pass through the respective pipelines (17-1 , Nitrogen gas intake pipeline; 17-2, Nitric oxide intake pipeline; 17-3, Oxygen intake pipeline) delivery, the gas flow of each pipeline passes through the respective flow controllers with display functions (2-1, flow rate Controller one; 2-2, flow controller two; 2-3, flow controller three) monitor and regulate respectively; after that, nitrogen 1-1, nitric oxide 1-2, oxygen 1-3 three-way gas confluence is A mixed gas inlet main path 18, after which the mixed gas has two branch paths, one is the normal test process, and the other is a bypass for adjustment and emergency; first close the main path gas path control of the gas path passing through the reaction chamber The valve 16-2 opens the bypass gas path control valve 16-1 on...

Embodiment 2

[0036] For the water-based photocatalytic denitrification test, the gas used in the gas storage cylinder includes nitrogen 1-1, nitric oxide 1-2, and oxygen 1-3, and the water vapor is provided by the saturated humidification device 4 . The three-way gas contained in the gas storage cylinder is transported through its own pipeline, and the gas flow of each pipeline is monitored and regulated by the flow controller with its own display function. After that, nitrogen 1-1, nitric oxide 1-2, The oxygen 1-3 three-way gas merges into a mixed gas inlet main road 18, and then the mixed gas passes through the saturated humidifying device 4 to become waste gas containing a certain amount of moisture. The mixed gas with water vapor has two branches, one is the normal test process, and the other is the bypass for adjustment and emergency; firstly close the main gas path control valve 16-2 of the gas path passing through the reaction chamber and open the bypass path. The bypass gas path co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com