ABS resin and PS resin separation system, separation method and application

A ABS resin and resin separation technology, applied in solid separation, recycling technology, flotation, etc., can solve the problems of difficult separation of ABS and PS, and achieve the effect of improving the efficiency of flotation separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

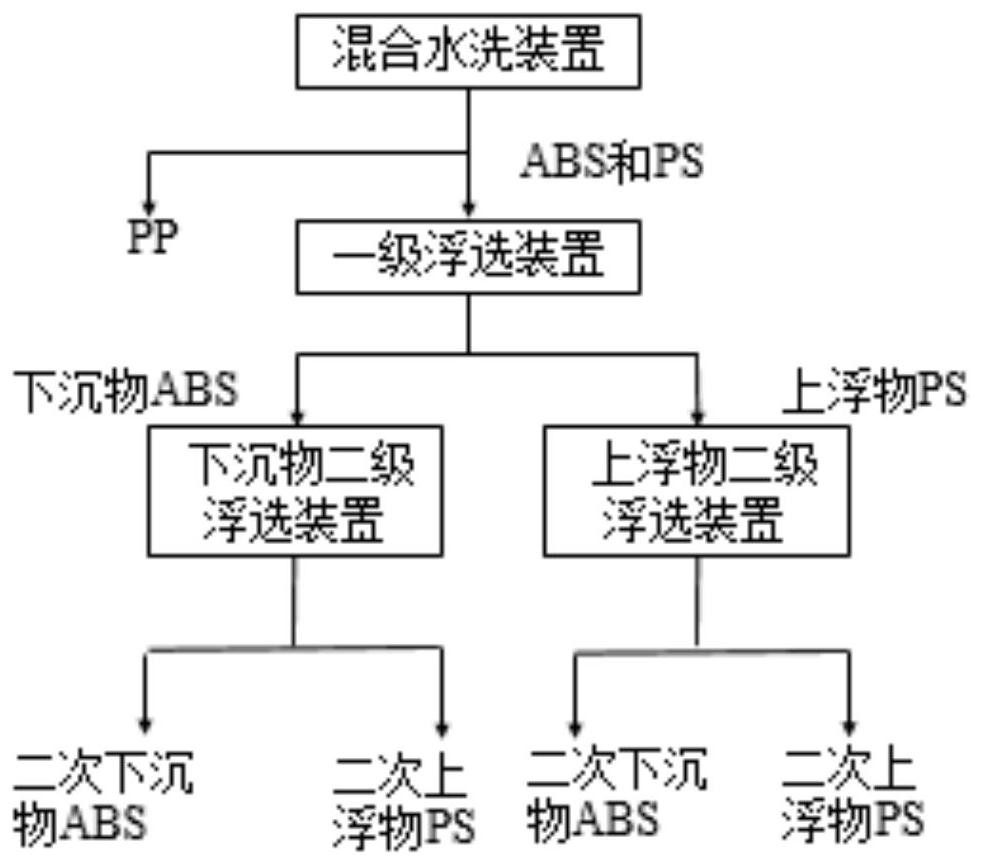

[0048] Mixed water washing: clean the mixture containing PP resin, ABS resin and PS resin with a diameter of 5-7mm and a thickness of 1-3mm, then put the mixture in a clear water pool for mixed water washing, and let it stand for 8 minutes to make it The flotation is stratified to obtain the mixed material of floating PP, sinking ABS and PS.

[0049] Primary flotation: Put clean water and primary flotation liquid in the primary flotation device, and then put the mixture of ABS and PS into the primary flotation device for primary flotation, among which, primary flotation The composition of the liquid is: the concentration of tannic acid is 250mg / L, the concentration of terpineol is 40mg / L, the stirring time of the primary flotation process is 3min, and the flotation time is 4min. The first-stage flotation process obtains the sinking ABS and the floating PS.

[0050] Secondary flotation of sinking matter: carry out secondary flotation of sinking matter on ABS, so that the PS in...

Embodiment 2

[0055] Mixed water washing: clean the mixture containing PP resin, ABS resin and PS resin with a diameter of 5-7mm and a thickness of 1-3mm, then put the mixture in a clear water pool for mixed water washing, and let it stand for 8 minutes to make it The flotation is stratified to obtain the mixed material of floating PP, sinking ABS and PS.

[0056] Primary flotation: Put clean water and primary flotation liquid in the primary flotation device, and then put the mixture of ABS and PS into the primary flotation device for primary flotation, among which, primary flotation The composition of the liquid is: the concentration of tannic acid is 240mg / L, the concentration of terpineol is 35mg / L, the stirring time of the primary flotation process is 3min, and the flotation time is 4min. The first-stage flotation process obtains the sinking ABS and the floating PS.

[0057] Secondary flotation of sinking matter: carry out secondary flotation of sinking matter on ABS, so that the PS in...

Embodiment 3

[0062] Mixed water washing: clean the mixture containing PP resin, ABS resin and PS resin with a diameter of 5-7mm and a thickness of 1-3mm, then put the mixture in a clear water pool for mixed water washing, and let it stand for 8 minutes to make it The flotation is stratified to obtain the mixed material of floating PP, sinking ABS and PS.

[0063] Primary flotation: Put clean water and primary flotation liquid in the primary flotation device, and then put the mixture of ABS and PS into the primary flotation device for primary flotation, among which, primary flotation The composition of the liquid is: the concentration of tannic acid is 260mg / L, the concentration of terpineol is 45mg / L, the stirring time of the primary flotation process is 3min, and the flotation time is 4min. The first-stage flotation process obtains the sinking ABS and the floating PS.

[0064] Secondary flotation of sinking matter: carry out secondary flotation of sinking matter on ABS, so that the PS in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com