A kind of electric flotation separation method of coal and rock micro-components

A technology of microscopic components and separation methods, applied in flotation, solid separation, selective deposition, etc., can solve problems such as insufficient effect, reduced flotation yield, cumbersome flotation process, etc., to achieve improved flotation Separation effect, improvement of wettability and sedimentation, effect of improvement of flotation separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

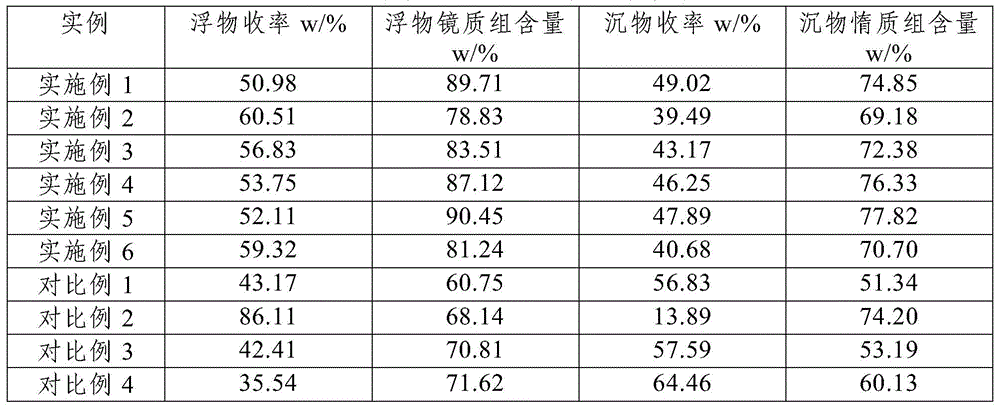

Examples

Embodiment 1

[0027] Step 1. Crushing and grinding the coal sample until the particle size is less than 0.074mm, then adding water to adjust the slurry to obtain a coal slurry with a concentration of 30g / L;

[0028] Step 2, adjust the temperature of the coal slurry described in step 1 to be 20°C, then add hydrochloric acid (5mol / L) until the pH value of the coal slurry is 2.0, then add the collector and stir evenly; the collector is oleic acid (Emulsified kerosene, stearic acid or humic acid can be used instead), the amount of collector added is 500g of collector per ton of raw coal;

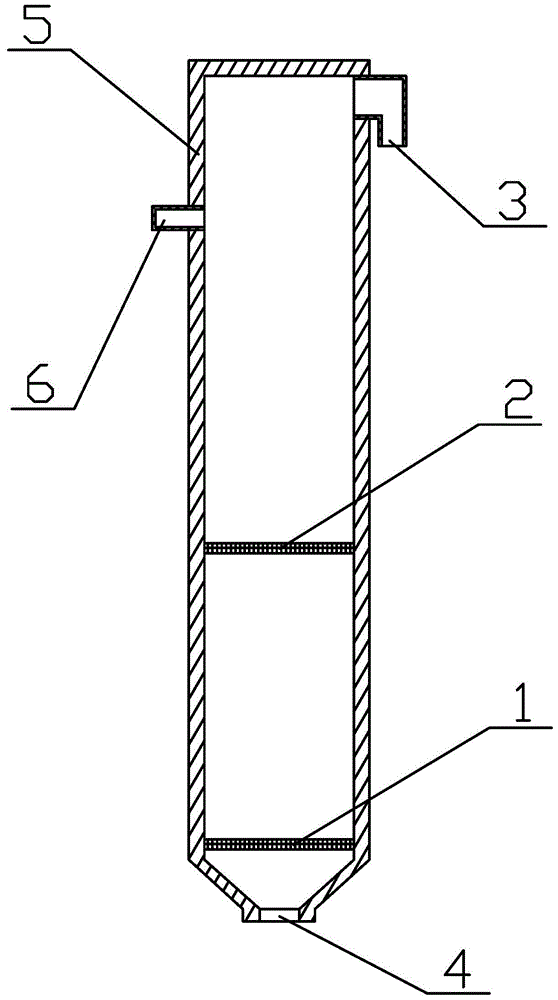

[0029] Step 3: Add the coal slurry that has been evenly stirred with the collector in step 2 into the flotation tube, so that both the positive electrode 1 and the negative electrode 2 are in the coal slurry, and then energize the positive electrode 1 and the negative electrode 2 in the flotation tube , the control current density is 3A / dm 2 , carry out electric flotation to the coal slurry in the flotation ...

Embodiment 2

[0031] Step 1. Crushing and grinding the coal sample until the particle size is less than 0.074mm, adding water to adjust the slurry to obtain a coal slurry with a concentration of 20g / L;

[0032] Step 2, adjust the temperature of the coal slurry described in step 1 to be 10°C, then add hydrochloric acid (2mol / L) until the pH value of the coal slurry is 3.0, then add collector and stir evenly; the collector is emulsified kerosene (Oleic acid, stearic acid or humic acid can be used instead), and the amount of collector added is 1000g of collector per ton of raw coal;

[0033] Step 3: Add the coal slurry that has been evenly stirred with the collector in step 2 into the flotation tube, so that both the positive electrode 1 and the negative electrode 2 are in the coal slurry, and then energize the positive electrode 1 and the negative electrode 2 in the flotation tube , the control current density is 2A / dm 2, carry out electric flotation to the coal slurry in the flotation tube,...

Embodiment 3

[0035] Step 1, crushing and grinding the coal sample until the particle size is less than 0.074mm, adding water to adjust the slurry to obtain a coal slurry with a concentration of 50g / L;

[0036] Step 2, adjust the temperature of the coal slurry described in step 1 to be 30°C, then add hydrochloric acid (5mol / L) to the pH value of the coal slurry to 4.0, then add the collector and stir evenly; the collector is stearin Acid (can be replaced by emulsified kerosene, oleic acid or humic acid), the amount of collector added is 750g of collector per ton of raw coal;

[0037] Step 3: Add the coal slurry that has been evenly stirred with the collector in step 2 into the flotation tube, so that both the positive electrode 1 and the negative electrode 2 are in the coal slurry, and then energize the positive electrode 1 and the negative electrode 2 in the flotation tube , the control current density is 1A / dm 2 , carry out electric flotation to the coal slurry in the flotation tube, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com