A kind of metal sulfide ore flotation inhibitor and its application

A sulfide ore and inhibitor technology, applied in flotation, solid separation and other directions, can solve the problems of difficulty in reducing the cost of mineral processing agents, loss of effective components, and large environmental pollution, and achieves a wide range of pH applications, easy degradation, and environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

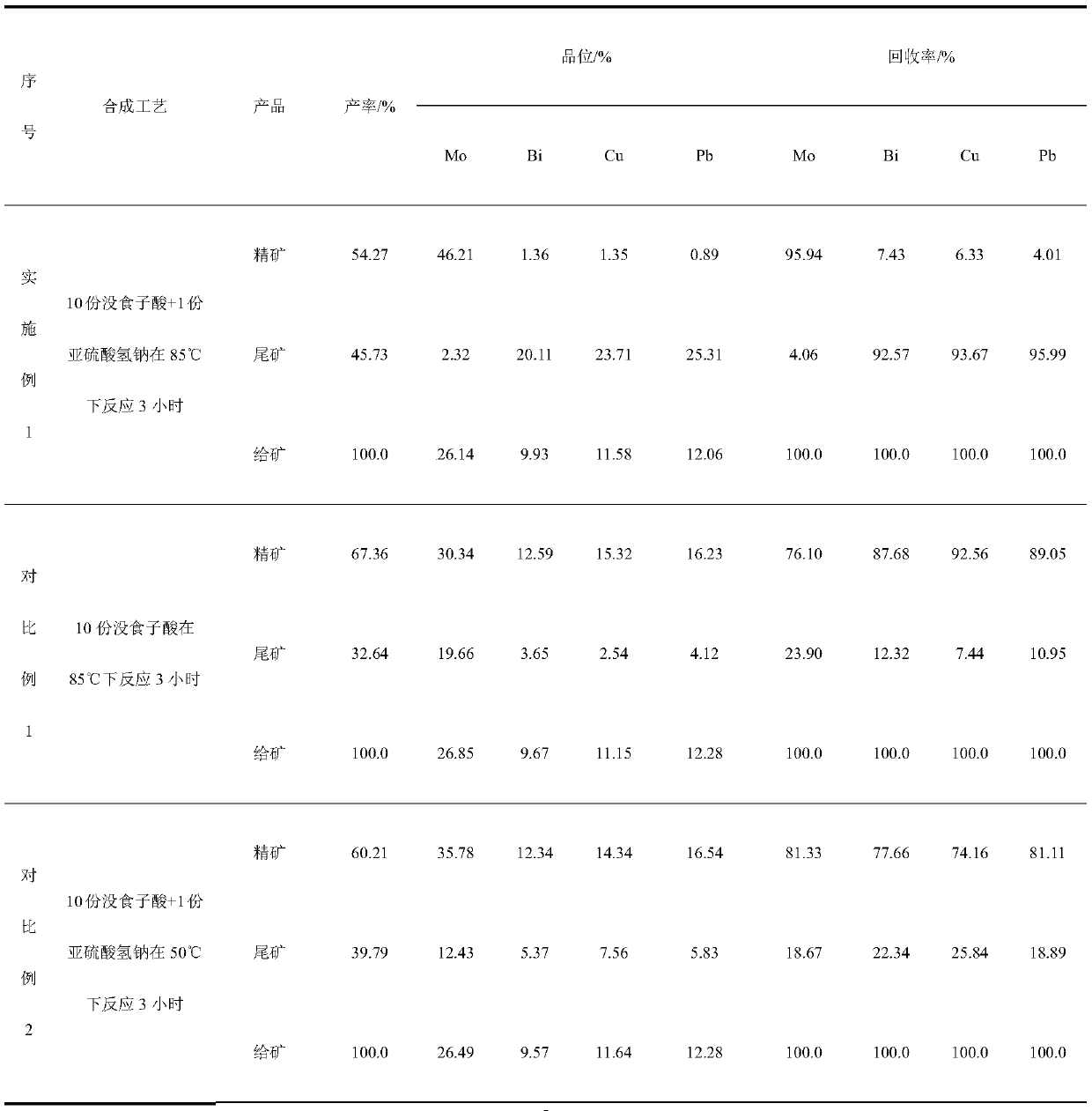

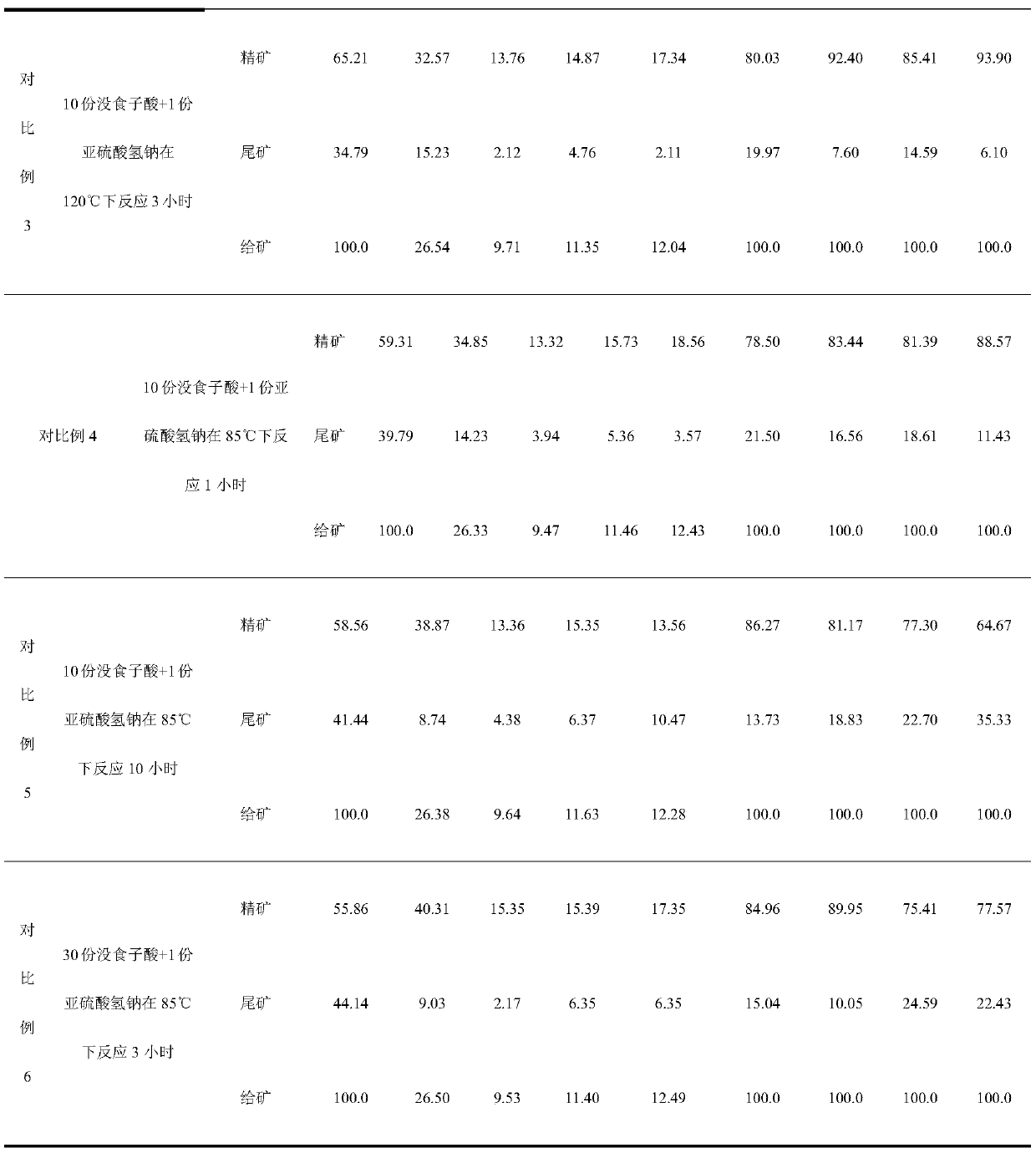

Examples

Embodiment 1

[0034] Add 10 parts of gallic acid and 30 parts of ultrapure water into a container equipped with a stirrer and a thermometer, mix and stir, add 1 part of sodium bisulfite after fully dissolving, heat in a water bath to 85°C, react for 3 hours, and cool to crystallize. The obtained pale yellow crystals are the inhibitor.

Embodiment 2

[0036] Add 20 parts of gallic acid and 30 parts of ultrapure water into a container equipped with a stirrer and a thermometer, mix and stir, add 2 parts of sodium bisulfite after fully dissolving, heat in a water bath to 75°C, react for 6 hours, and cool to crystallize. The obtained pale yellow crystals are the inhibitor.

Embodiment 3

[0038] Add 20 parts of gallic acid and 60 parts of ultrapure water into a container equipped with a stirrer and a thermometer, mix and stir, add 1 part of sodium bisulfite after fully dissolving, heat in a water bath to 95°C, react for 3 hours and then cool to crystallize. The obtained pale yellow crystals are the inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com