Mold pressing equipment

An equipment and molding technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as inconvenience in demoulding, and achieve the effect of avoiding too tight combination, good use effect, and improving separation convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

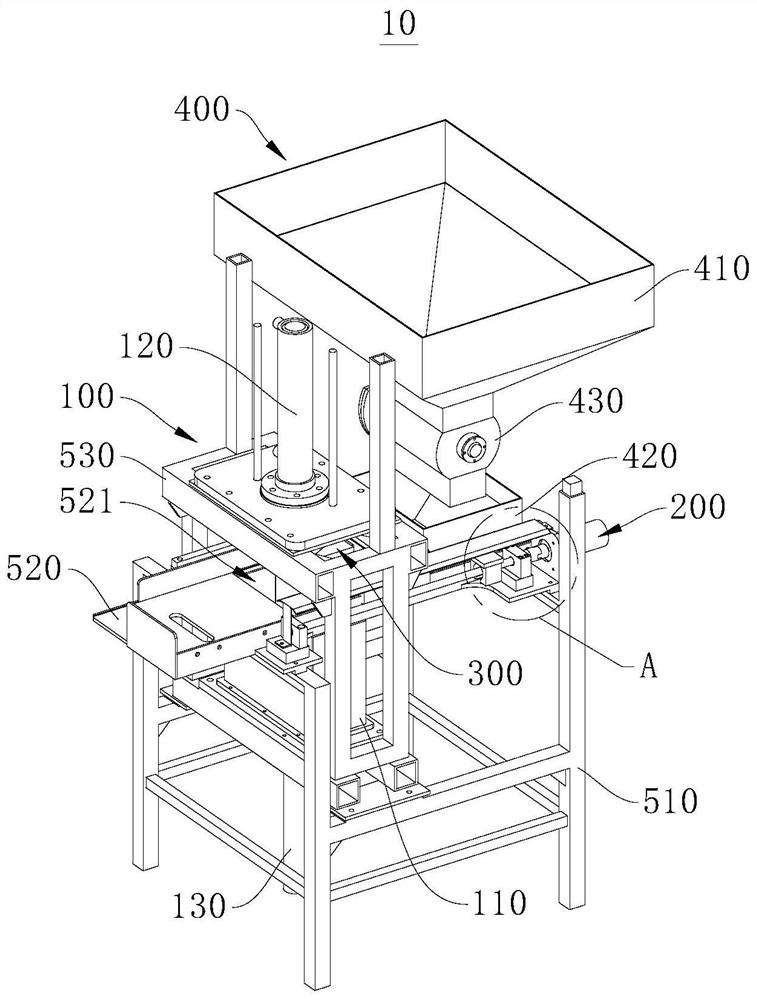

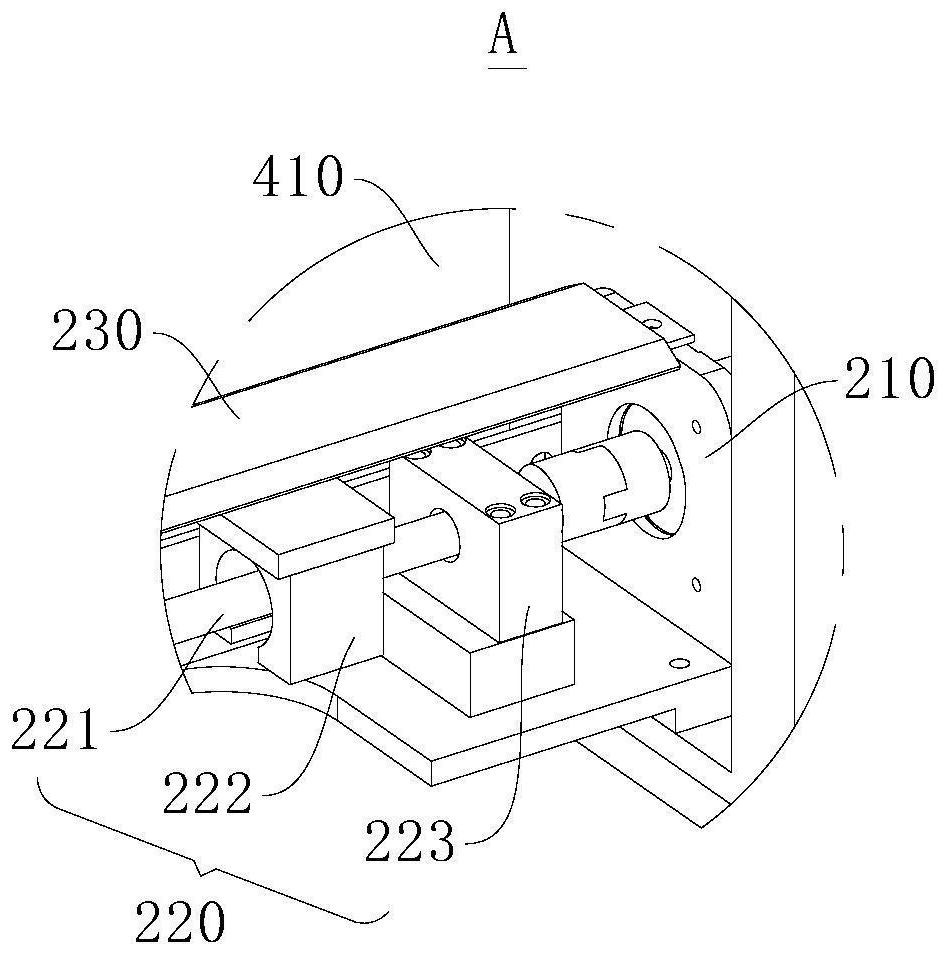

[0053] refer to figure 1 As shown, the present invention provides a molding equipment 10, which includes a compacting device 100, a moving device 200 and a frame 500; the frame 500 is used as an installation carrier for fixedly installing the compacting device 100 and the moving device 200, The device 100 is used for accommodating raw materials and performing pressing operation to form a green body, and can drive the green body to move onto the frame 500 , and the moving device 200 is used to transport the green body on the frame 500 .

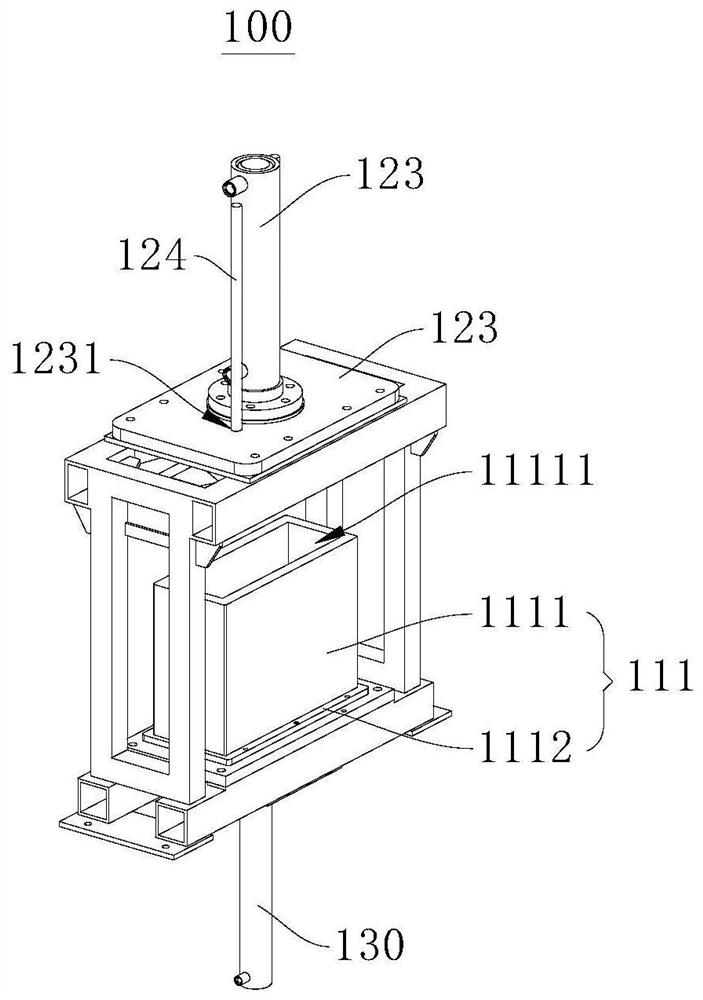

[0054] Specifically, the frame 500 is provided with a feeding hole 521, and the frame 500 is used to carry the green body; please continue to refer to image 3 and Figure 4The compact device 100 includes a mold mechanism 110, a compact assembly 120 and an ejector assembly 130. The mold mechanism 110 is provided with a cavity 11111 connected to the feed hole 521. The compact assembly 120 and the mold mechanism 110 are relatively movable, and ...

Embodiment 2

[0086] This embodiment also provides a molding device 10. This embodiment is basically the same as Embodiment 1, and the symbol meanings are the same as Embodiment 1. Only the differences are listed below:

[0087] refer to figure 1 As shown, the molding equipment 10 of this embodiment also includes a demoulding mechanism 300, which is movable relative to the frame 500; the demoulding mechanism 300 is internally provided with a liquid storage chamber 311 for accommodating the demoulding agent, and the demoulding mechanism The mechanism 300 is provided with a liquid discharge hole 312 that communicates with the liquid storage chamber 311; the moving device 200 is used to drive the demoulding mechanism 300 to move, so that the liquid discharge hole 312 is connected to or disconnected from the mold cavity 11111; the mobile device 200 also It is used to transport the green body output from the cavity 11111.

[0088] In the molding equipment 10 of this embodiment, by setting the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com