Material transplanting and conveying AGV trolley

A technology for trolleys and materials, applied to conveyors, mechanical conveyors, motor vehicles, etc., can solve problems such as inability to improve work efficiency and inability to fully realize unmanned automatic control, so as to achieve unmanned automatic control and prevent emergency events , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

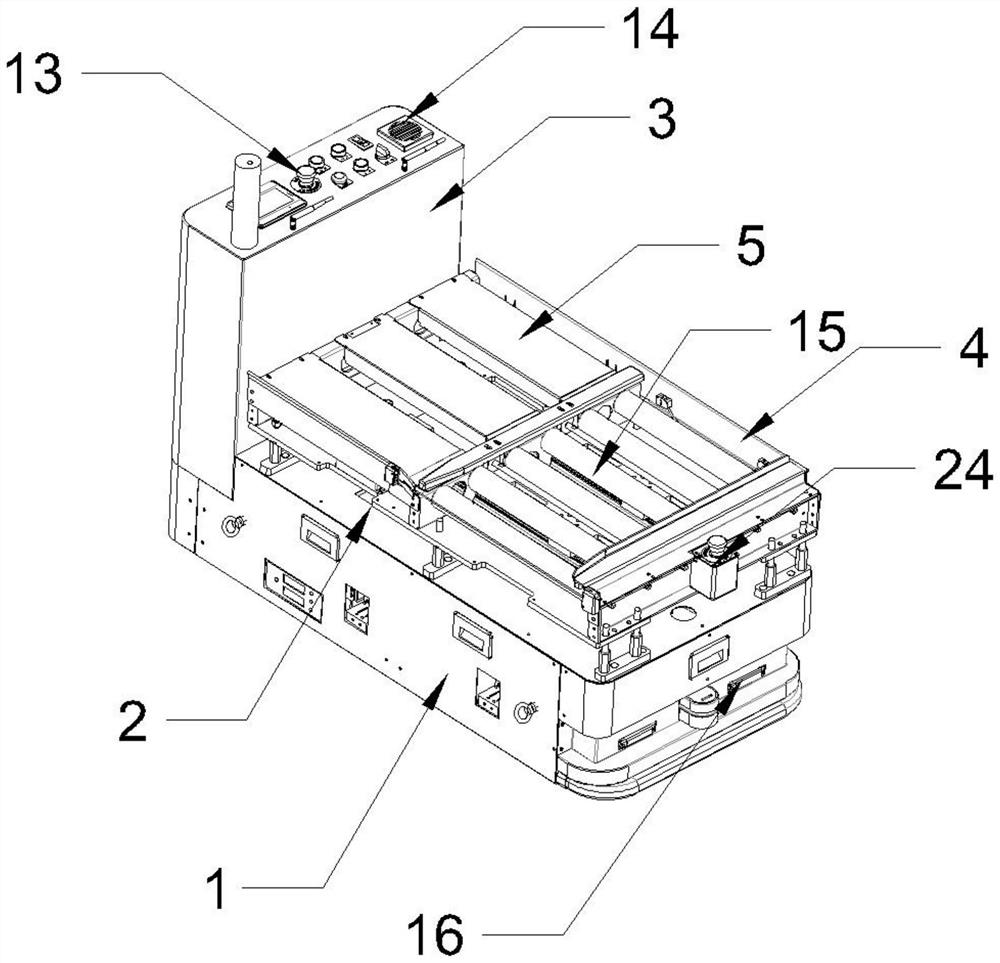

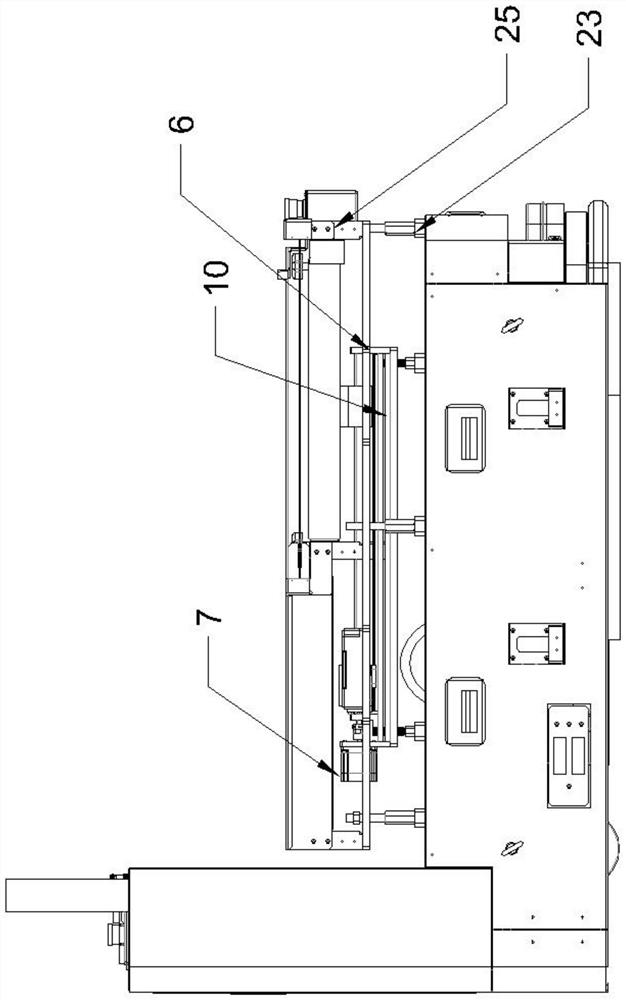

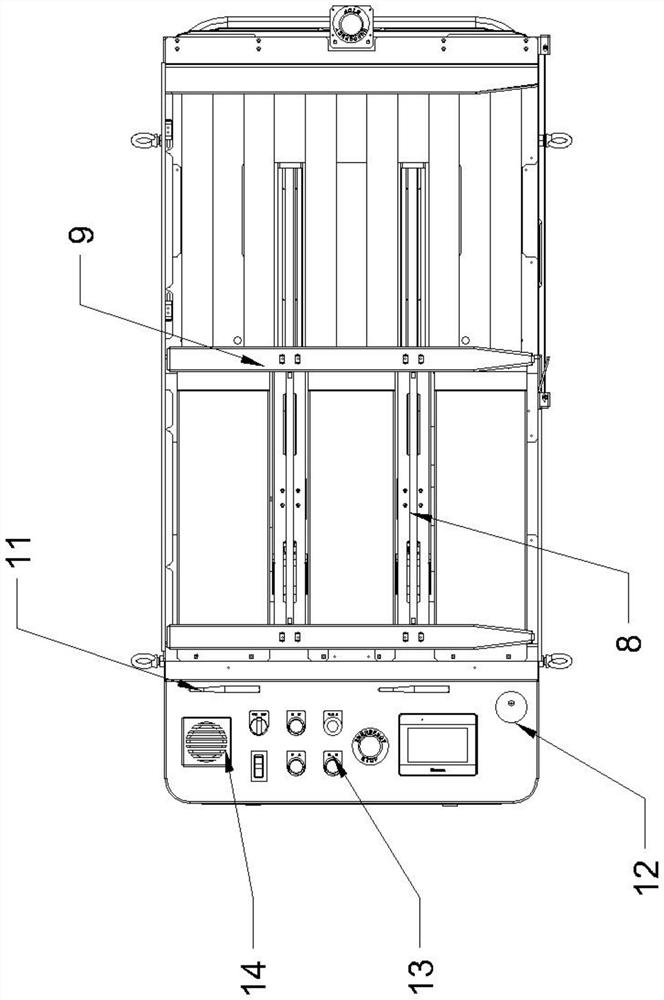

[0022] like Figure 1-4 As shown, a material transplanting and conveying AGV trolley includes a base 1, the upper end of the base 1 is provided with a support plate 2, a support frame 25 and a linear positioning mechanism 6 in turn, and the upper end of the linear positioning mechanism 6 is provided with a first workbench 4 and a second The workbench 5 and the linear positioning mechanism 6 include a servo motor 7, one side of the servo motor 7 is connected to the screw rod 10, a linear slide rail 8 is provided above the screw rod 10, a plurality of rollers 15 are arranged inside the second workbench 5, and a base 1 An electric control box 3 is arranged on the side, and an antenna 11, a status light 12, a control switch 13 and a music box 15 are arranged on the top of the electric control box. , One side of the steering mechanism 22 is provided with an emergency charging group 20 and a motor 21 .

[0023] Preferably, both ends of the first workbench 4 are provided with guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com