Special anti-rust oil for zinc-aluminum-magnesium plate and preparation method of special anti-rust oil

A technology of anti-rust oil and zinc-aluminum-magnesium, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as affecting subsequent use, difficulty in cleaning, and inability to inhibit discoloration of galvanized aluminum-magnesium plates, so as to achieve inhibition of discoloration, Easy to clean and excellent melting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

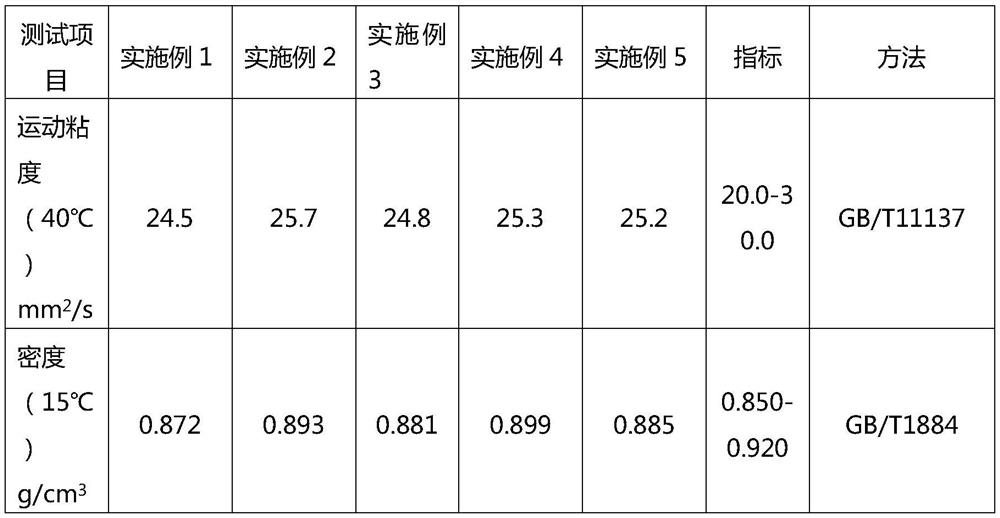

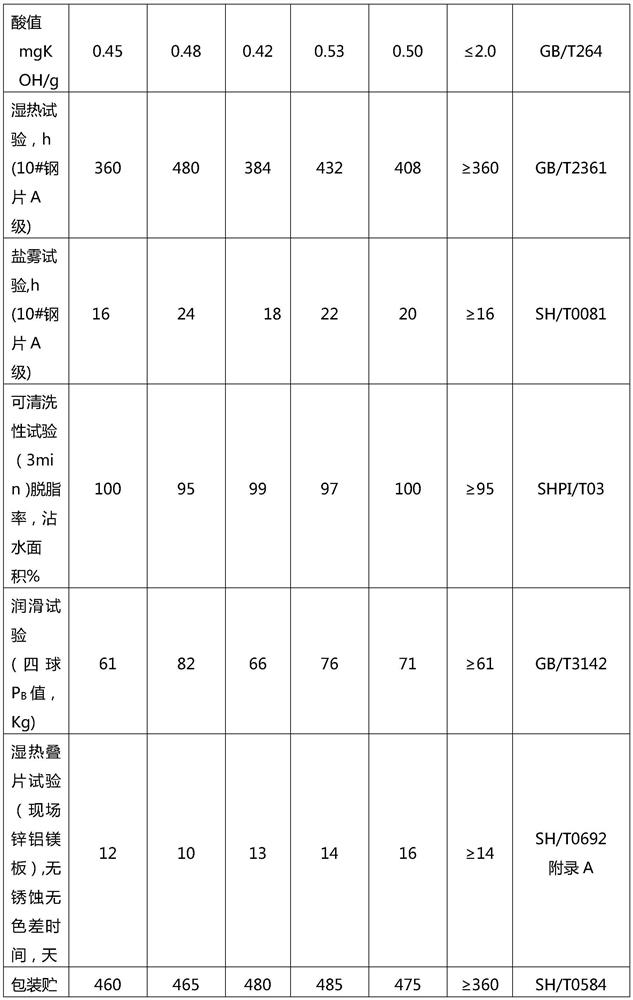

Examples

preparation example Construction

[0027] In an embodiment of the present invention, the preparation method of the above-mentioned anti-rust oil includes:

[0028] Take each component according to the formula of the above-mentioned anti-rust oil for subsequent use;

[0029] Put the mixture of sulfonate and carboxylate, sulfonate and carboxylic acid derivatives into the reaction kettle, the temperature in the kettle is controlled within the range of 100-130°C, the air flow rate is 2-6L / min, and the reaction time is 2-5h , to obtain the first reaction mixture, cooled for subsequent use;

[0030] Add the first mixture obtained from the reaction, lanoic acid and polyol synthetic fat, fatty acid ester, and mineral oil into the reaction kettle, heat to 80-100°C, stir evenly, keep the temperature constant for 1-3h, cool down to 50-60°C and then keep the temperature constant to obtain Second mixed reactant. Then add metal deactivator and non-ionic surfactant, and stir evenly.

[0031] In a preferred embodiment of th...

Embodiment 1

[0035] A kind of antirust oil, comprises the raw material of following percentage by weight:

[0036] Sulfonate and carboxylate mixture 6.5%, sulfonate and carboxylic acid derivatives 1%, wool acid and polyol synthetic fat (LY10) 0.1%, metal deactivator 0.1%, fatty acid ester 1.5%, non-ionic surface Active agent 1%, synthetic mineral oil 89.8%.

[0037] Take each component according to the formula of the above-mentioned anti-rust oil for subsequent use;

[0038] Add the mixture of sulfonate and carboxylate and sulfonate and carboxylic acid derivatives into the reaction kettle, the temperature inside the kettle is controlled within the range of 105°C, the air flow rate is 3L / min, and the reaction time is 3h to obtain the first reaction mixture , cooling down for standby;

[0039] Add the first mixture obtained from the reaction, lanoic acid and polyol synthetic fat, fatty acid ester, and mineral oil into the reaction kettle, heat to 80°C, stir evenly, keep the temperature con...

Embodiment 2

[0041] A kind of antirust oil, comprises the raw material of following percentage by weight:

[0042] Sulfonate and carboxylate mixture 13.5%, sulfonate and carboxylic acid derivatives 3%, wool acid and polyol synthetic fat 1%, metal deactivator 1%, fatty acid ester 5%, nonionic surfactant 5 %, synthetic mineral oil 71.5%.

[0043] Take each component according to the formula of the above-mentioned anti-rust oil for subsequent use;

[0044] Add the mixture of sulfonate and carboxylate, sulfonate and carboxylic acid derivatives into the reaction kettle, the temperature in the kettle is controlled at 130°C, the air flow rate is 6L / min, and the reaction time is 5h to obtain the first reaction mixture, and cool cooling standby;

[0045] Add the first mixture obtained from the reaction, lanoic acid and polyol synthetic fat, fatty acid ester, and mineral oil into the reaction kettle, heat to 100°C, stir evenly, keep the temperature constant for 3 hours, cool down to 55°C, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com