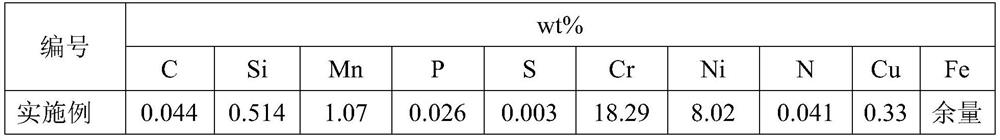

A kind of stainless steel belt for water tank and preparation method thereof

A stainless steel belt and water tank technology, applied in the field of stainless steel, can solve problems such as increased cost and environmental protection problems, and achieve the effect of avoiding cracking, saving production cost and time cost, and ensuring elongation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

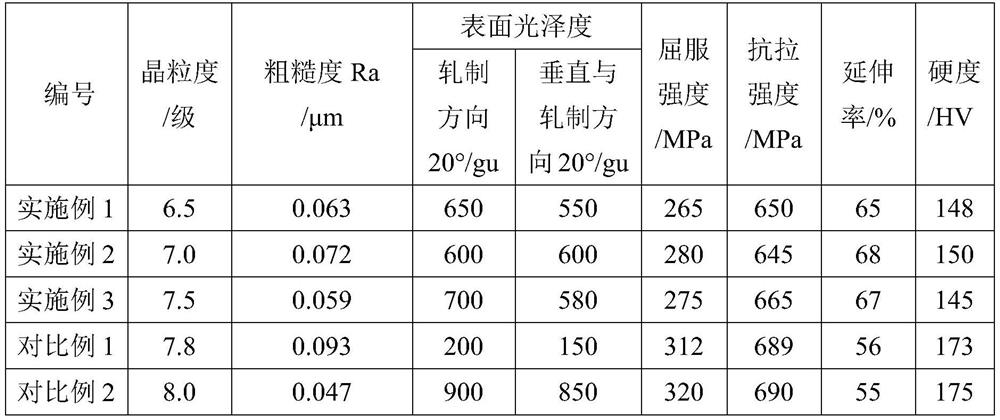

Embodiment 1

[0025] The hot-rolled coil is annealed and pickled at a temperature of 1100 ℃, and the holding time is 1min; the rough rolling reduction rate is 27%, and then the microscopic defects on the surface of the strip are removed by rough grinding. Rolled by work rolls with a roughness of 0.22μm, the finishing rolling reduction rate is 64%; the bright annealing temperature of the finished coil is 1150 ° C, the holding time is 70 seconds, and the speed is reduced by 10% on the basis of conventional annealing TV; the flat elongation is 0.5%.

Embodiment 2

[0027] The hot-rolled coil is annealed and pickled at a temperature of 1080 ℃, and the holding time is 2 minutes; the rough rolling reduction rate is 30%, and then the microscopic defects on the surface of the strip are removed by rough grinding. Rolled by work rolls with a roughness of 0.25μm, the finishing rolling reduction rate is 70%; the bright annealing temperature of the finished coil is 1140℃, the holding time is 1min, and the speed is reduced by 8% on the basis of conventional annealing TV; the flat elongation is 0.6 %.

Embodiment 3

[0029] The hot-rolled coil is annealed and pickled at a temperature of 1120 °C, and the holding time is 5 minutes; the rough rolling reduction rate is 35%, and then the microscopic defects on the surface of the strip are removed by rough grinding. For the second time, a work roll with a roughness of 0.22 μm was used for rolling, and the finishing rolling reduction rate was 80%; the bright annealing temperature of the finished coil was 1150 ° C, the holding time was 100 seconds, and the speed was reduced by 15% on the basis of conventional annealing TV; rate 0.3%.

[0030] T-the English initials of the thickness, V-the maximum process speed of the strip, the product of the two is the TV value, which reflects the annealing ability of the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com