Close-range multi-branch sidetrack drilling tool and drilling method for a directional hole in a coal mine

A directional hole, close-range technology, applied in directional drilling, earth-moving drilling, wellbore/well components, etc., can solve the problems of large spacing between branch holes, low branch efficiency of sidetracking, and inability to run branch holes, avoiding the Collapse failure, ensuring the effect of disaster prevention and control, and avoiding the effect of the blank zone of disaster prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

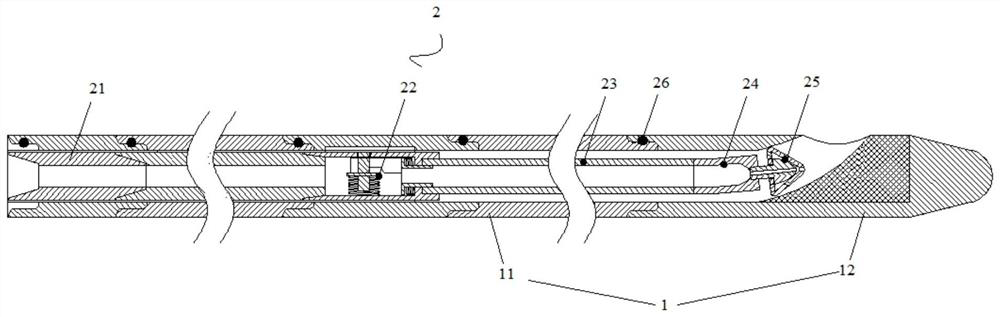

[0061] This embodiment discloses a short-distance multi-branch sidetrack drilling tool for a directional hole in a coal mine. The drilling tool includes a steerable drilling tool 1 and a flexible branch drilling tool 2 that can be inserted into the steerable drilling tool 1. Specifically, the steerable drilling tool The inner diameter of 1 matches the outer diameter of the flexible branch drill 2.

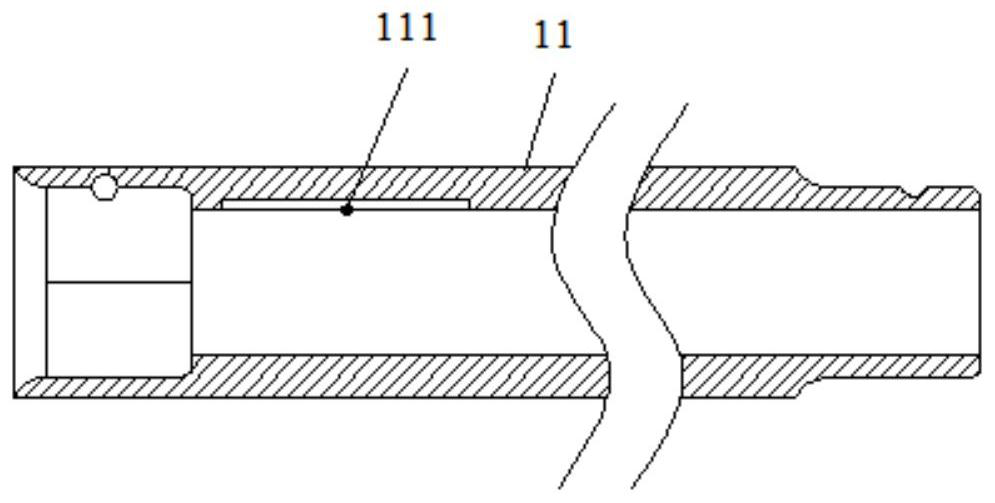

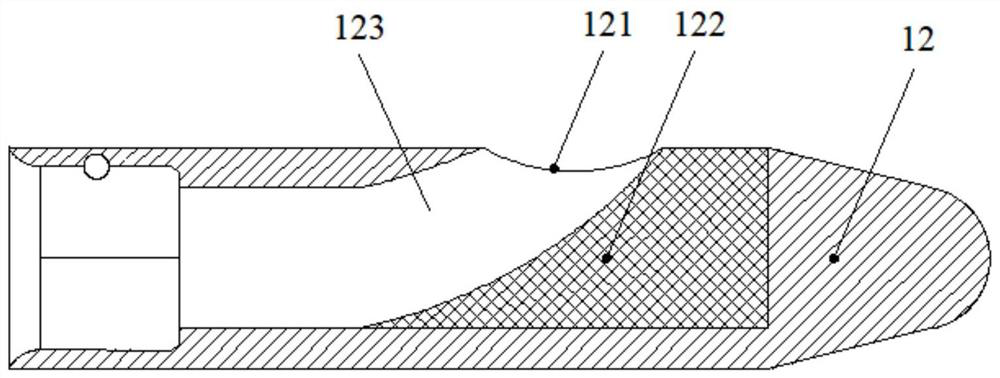

[0062] A section of positioning groove 111 is provided on the inner wall of the pilot drilling tool 1, such as figure 2 As shown, there is a guide port 121 on the wall of the guide sleeve 12 for the flexible branch drilling tool 2 to extend, such as image 3 shown.

[0063] The pilot drilling tool 1 includes a guide sleeve 12 connected with an outer sleeve 11 and the outer sleeve 11 , and the inner holes of the outer sleeve 11 and the guide sleeve 12 have the same diameter. Preferably, the outer sleeve 11 and the guide sleeve 12 are connected by a hexagonal male joint and a hexa...

Embodiment 2

[0074] In order to realize the completion of the screen pipe of the branch hole 5 and avoid the collapse and failure of the branch hole, a screen pipe completion drill 3 is also provided on the basis of the drilling tool of Example 1.

[0075] like Figure 8 As shown, the screen tube completion drilling tool 3 of the present embodiment includes a screen tube 31 and a push section 32 connected to the screen tube 31. The push section 32 is provided with a channel, which is used for the transmission of gas and the like in the branch hole 5. circulation. The channel is provided with a valve body 322 , and the high-pressure flushing liquid first pushes the valve body 33 to close the flow channel, and then the flushing liquid pushes the entire screen tube completion drilling tool 3 into the branch hole 5 .

[0076] In this embodiment, as Figure 9 As shown, the push short joint 32 includes a housing 321, a valve body 322 and a third elastic member 323, and the third elastic member...

Embodiment 3

[0080] The present embodiment discloses a method for short-distance multi-branch sidetracking in a directional hole in a coal mine. Specifically, the drilling tool described in Embodiment 1 is used to drill the branch hole, which specifically includes the following steps:

[0081] Step 1: Drill into the main hole. Specifically, after constructing the main hole 4 with a conventional directional drilling tool, exit the directional drilling tool in the hole; , connect the guide sleeve 12 and the outer sleeve 11 in turn;

[0082] Step 2: Adjust the direction of the pilot hole 121: After adjusting the direction of the pilot hole 121 of the pilot drill 1 to make it consistent with the direction of the designed sidetrack branch, lock the pilot hole 1. Specifically, when adjusting, slowly rotate the pilot drill 1 , since the orientation of the pin 26 is the same as the orientation of the guide port 121 , it can be adjusted according to the orientation of the pin 26 .

[0083] Step 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com