Distributed optical fiber sensor

A distributed optical fiber and optical fiber sensor technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of measurement interruption, increase measurement cost, shorten service life, etc., to reduce measurement cost, The effect of reducing measurement time and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

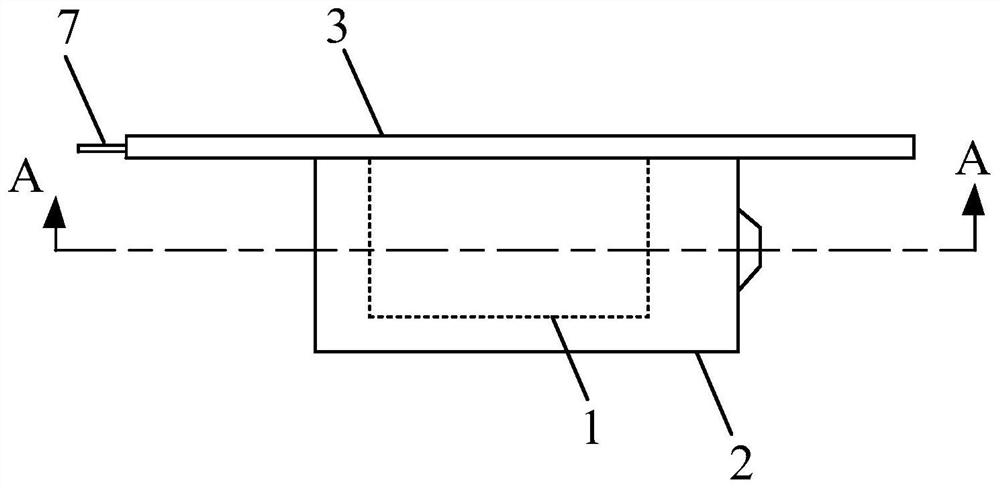

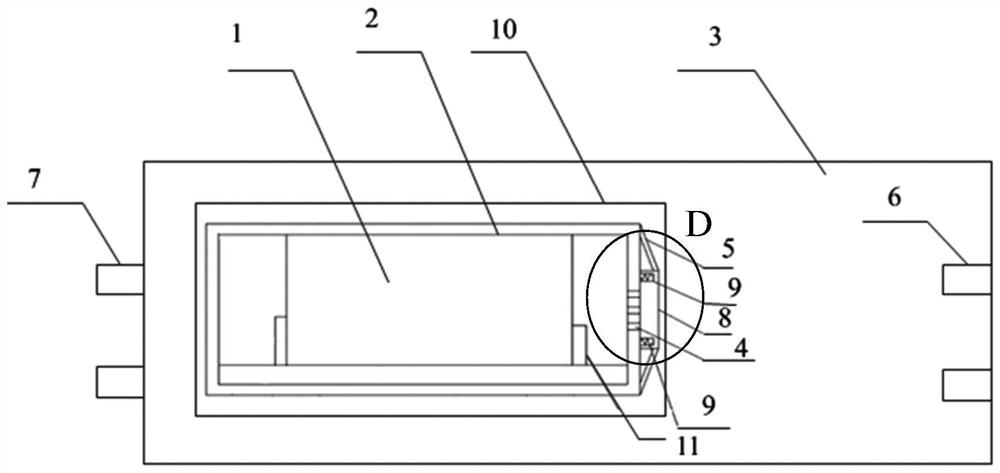

[0031] Such as figure 1 and figure 2 As shown, a distributed optical fiber sensor provided by an embodiment of the present invention includes an optical fiber sensor body 1 , a housing 2 and a metal substrate 3 .

[0032] Wherein, the fiber optic sensor body 1 can be a fiber optic sensor, and the fiber optic sensor is a sensor that converts the state of the measured object into a measurable optical signal. The interaction between the modulator and the external measured parameters changes the optical properties of the light, such as light intensity, wavelength, frequency, phase, polarization state, etc., and becomes a modulated optical signal, which is then sent to the optoelectronic device through the optical fiber. The parameters of the measured object are obtained after the demodulator.

[0033] The metal substrate 3 can be a flat metal plate, preferably a square aluminum plate, so that the aluminum plate has good electrical and thermal conductivity, and the aluminum plat...

Embodiment 2

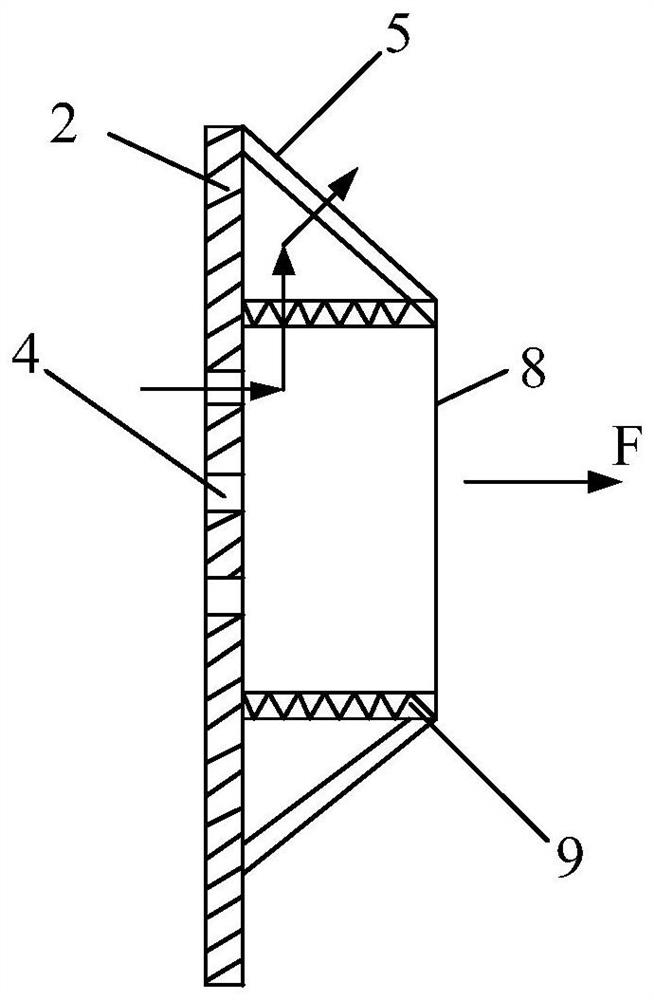

[0038] The embodiment of the present invention is optimized on the basis of the foregoing embodiment one, such as figure 1 and figure 2 As shown, a distributed optical fiber sensor provided by the embodiment of the present invention includes an optical fiber sensor body 1, a housing 2, and a metal substrate 3. The optical fiber sensor body 1 is fixed inside the housing 2, and the side wall of the housing 2 is provided with cooling holes. 4 and the filter screen 5 covering the cooling holes 4, the metal substrate 3 is provided with a mounting groove 10 and a welding groove, the shell 2 is connected to the metal substrate 3 through the mounting groove 10, and the metal substrate 3 is connected to the object to be measured through the welding groove.

[0039] Such as figure 2As shown, in an optional embodiment of the present invention, a fixing column 11 is provided in the housing 2, and the fixing column 11 is used to fix the fiber sensor body 1. Column 11, wherein, the sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com