Corrosive liquid corrosion system of chip burr etching machine

A technology of etching solution and etching machine, which is used in metal processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of insufficient high-voltage electric pulse processing efficiency and difficult chip workpieces, and achieve good corrosion cutting efficiency and removal. The effect of good effect and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

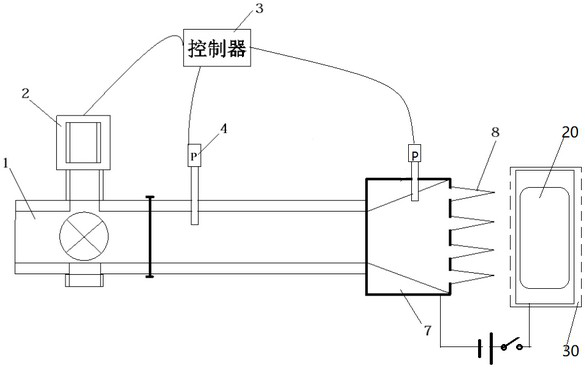

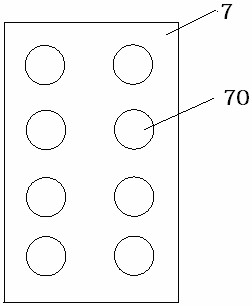

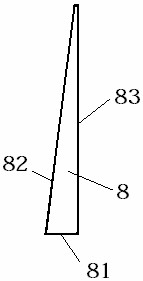

[0026] Such as figure 1 In the corrosive liquid etching system of the chip burr etching machine shown, one side of the adapter is connected to the rear end of the circular pipeline conveyed by the corrosive liquid. The other side of the adapter is a rectangular surface, and the rectangular surface has two rows of parallel There are a plurality of small liquid outlet holes, each of which is connected with a nozzle, and the nozzle is a tapered nozzle with a pipe diameter changing from thick to thin.

[0027] A booster pump is connected to the front end of the circular pipeline, a pressure gauge is arranged on the pipeline, and the pressure signal of the pressure gauge is transmitted to the controller, which is connected to control the pressurization state of the electric booster pump.

[0028] The cross-sectional area of the inner cavity of the adapter is larger than the cross-sectional area of the circular pipeline, and the pipe diameter cross-sectional area of the multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com