Quality and safety detection device and method for construction site

A safety detection and construction site technology, applied in electromagnetic wave transmission systems, electrical components, transmission systems, etc., can solve problems such as low work efficiency, waste, and unsmooth cable blowing, so as to improve work efficiency, save time, and facilitate on-site The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

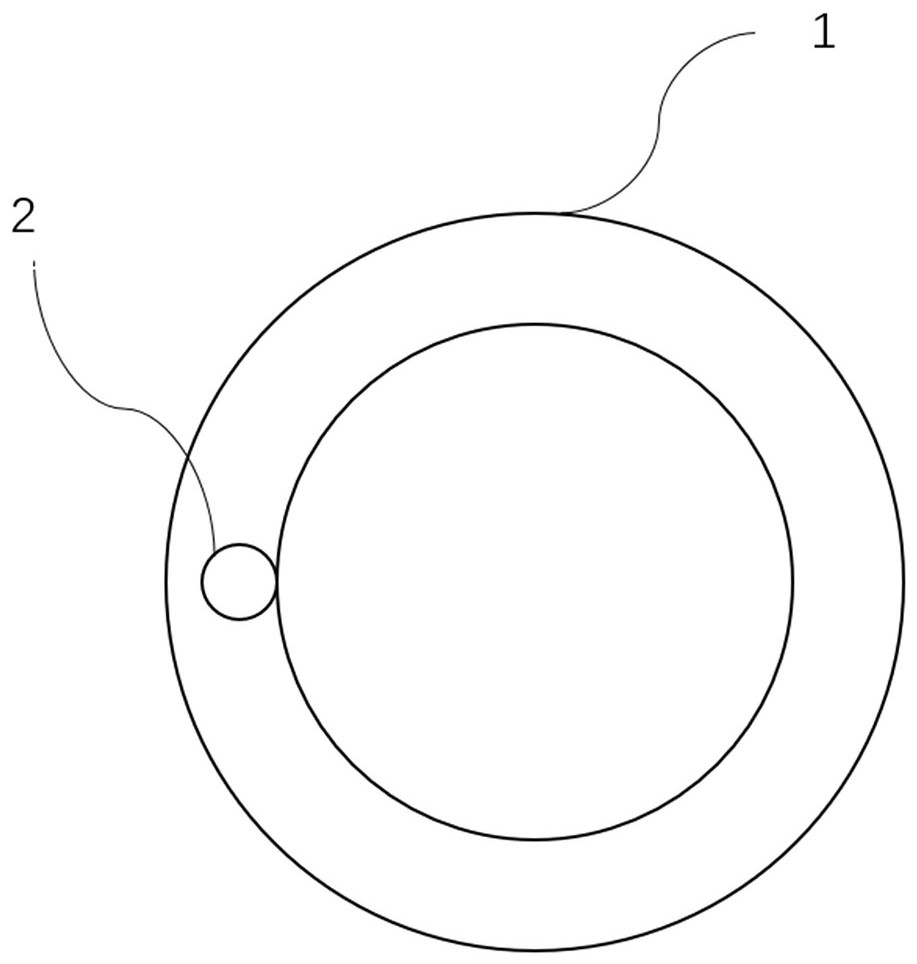

[0026] Figure 1-2 As shown, a technical scheme that the present invention adopts is: the quality of construction site, safety detection device, comprise blowing cable pipe 1, optical fiber 2, optical fiber union, optical time domain reflectometer; Described optical fiber 2 is arranged on blowing cable pipe 1 In the tube wall; the optical fiber 2 is connected with the optical fiber union; the optical time domain reflectometer is connected with the optical fiber union.

[0027] Preferably, the optical fiber 2 is arranged inside the pipe wall of the cable blowing pipe 1 .

[0028] Further, the length of the optical fiber 2 is greater than the length of the cable blowing pipe 1 , and the two ends of the optical fiber 2 are exposed from the two ends of the cable blowing pipe 1 .

[0029] Preferably, the optical time domain reflectometer can detect from both ends of the optical fiber 2 respectively.

[0030] Further, the optical time domain reflectometer is used to detect the dis...

Embodiment 2

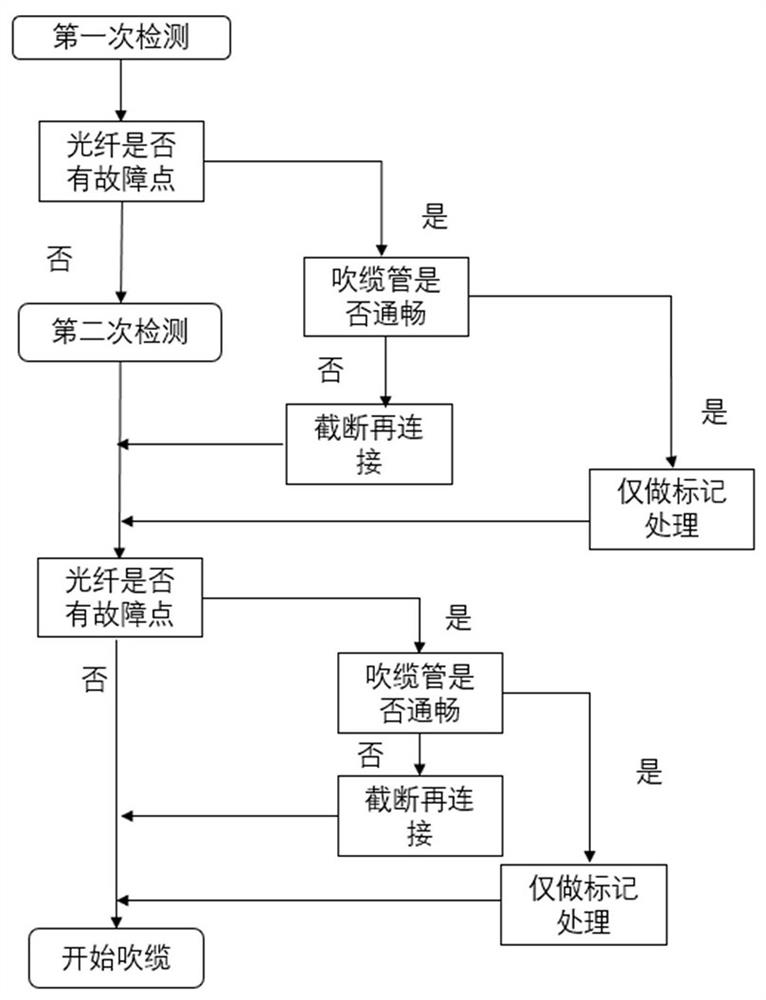

[0034] The present invention also provides a quality and safety detection method on the construction site, using the above-mentioned device, comprising the following steps:

[0035] Step 1. When distributing the disk, use the fusion splicer to make the optical fiber 2 and the optical fiber union hot-melt, connect the optical time domain reflectometer and the optical fiber union, and the optical time domain reflectometer first detects whether the optical fiber 2 in the cable blowing pipe 1 is If there is a fault point, if there is a fault point in the optical fiber 2, the optical time domain reflectometer will detect the distance between the fault point and the detection end, mark the position of the fault point and check whether the cable blowing tube 1 is unobstructed; if the cable blowing tube 1 is unobstructed, work The personnel only mark it; if the cable blowing pipe 1 is not smooth, the staff cuts off the unblocked cable blowing pipe 1, and then connects the two blowing c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap