Agricultural pollination unmanned aerial vehicle with efficient pollination function

A UAV and functional technology, applied in the field of UAV, can solve the problems of pollen damage, pollen collision with fan leaves, affecting pollination effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

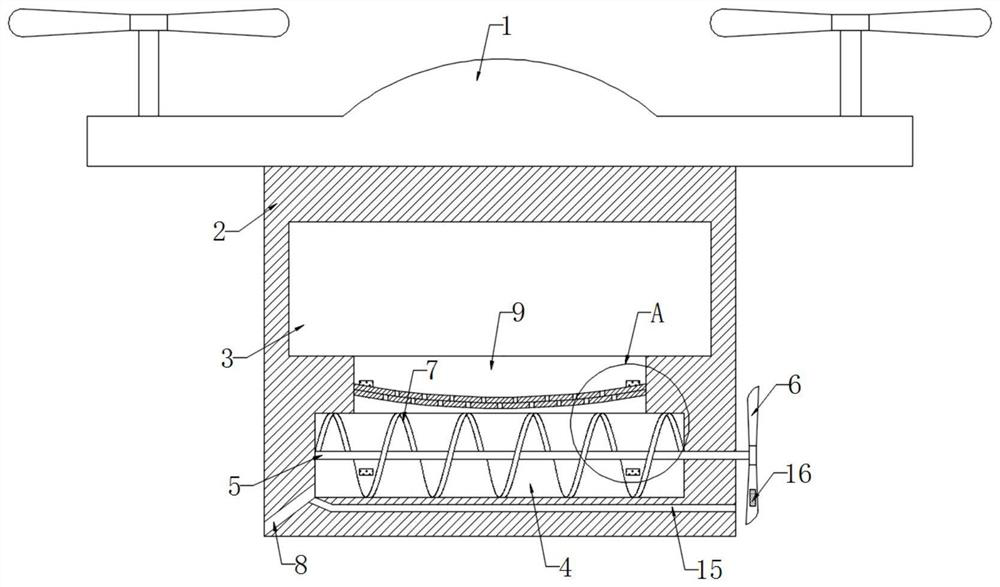

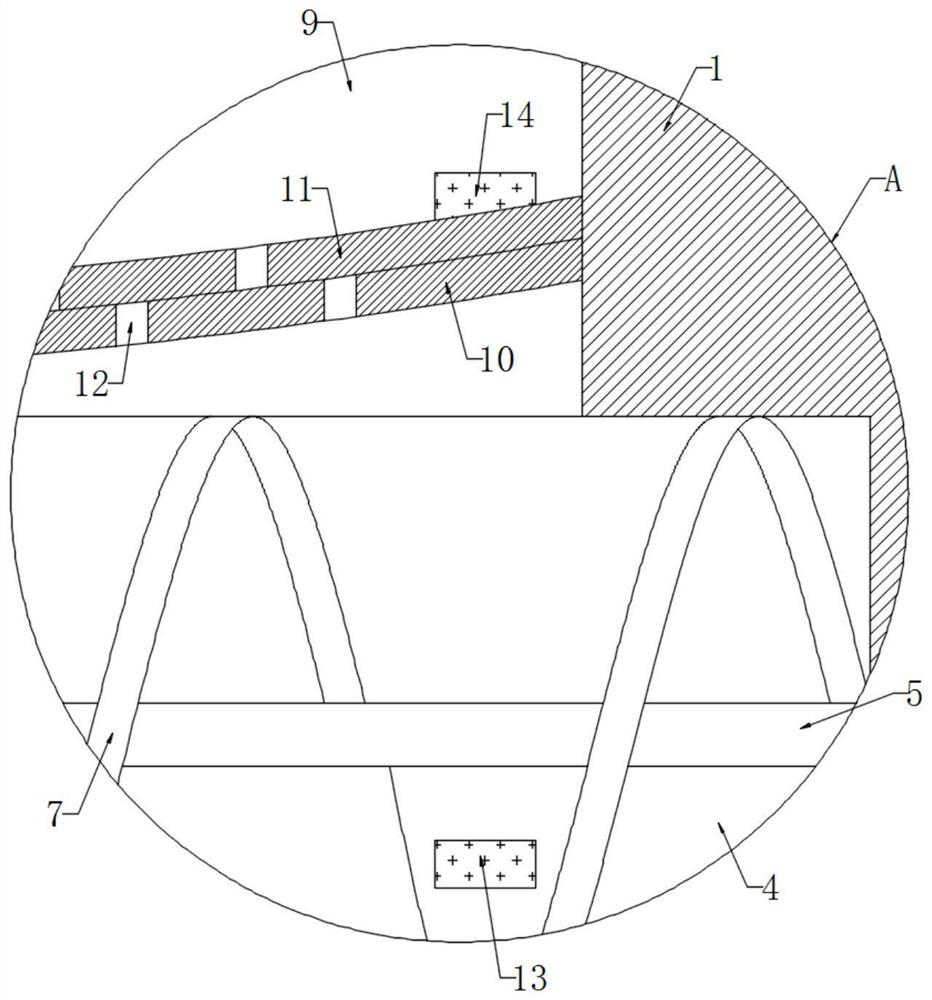

[0023] refer to Figure 1-2 , an agricultural pollination UAV with high-efficiency pollination function, comprising a body 1, a fixed block 2 is fixedly connected to the lower end of the body 1, a powder storage cavity 3 is opened in the fixed block 2, and a pushing cavity 4 is opened at the lower end of the fixed block 2, The inner wall of the pushing chamber 4 is rotatably connected with a rotating shaft 5, and the side wall of the rotating shaft 5 is fixedly connected with a spiral stirring blade 7, and the side wall of the spiral stirring blade 7 is sealed and rotatingly connected with the inner wall of the pushing chamber 4, so that the rotation of the spiral stirring blade 7 can rotate the The pollen in the cavity 4 is pushed out, and one end of the rotating shaft 5 runs through the side wall of the fixed block 2 and is fixedly connected with a plurality of impellers 6. The pushing cavity 4 is provided with a discharge hole 8 inclined downwards away from the inner wall of...

Embodiment 2

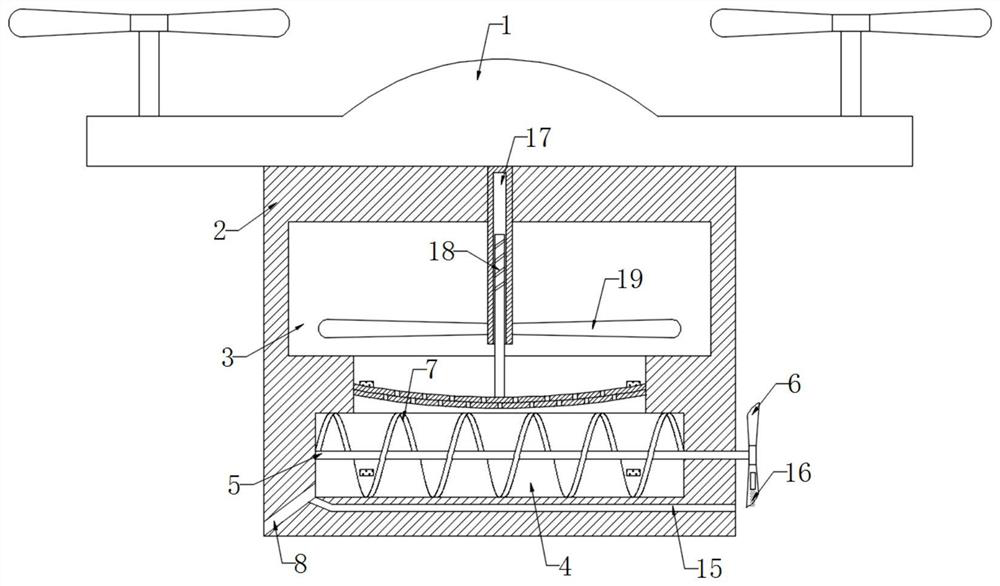

[0031] refer to image 3 , the difference from Embodiment 1 is that the inner top of the fixed block 2 is rotatably connected with a sleeve 17, the inner wall of the sleeve 17 is threadedly connected with a lead screw 18, the lower end of the lead screw 18 is fixedly connected with the upper end of the slide plate 11, and the lower end of the side wall of the sleeve 17 is fixed A plurality of stirring rods 19 are connected.

[0032] It should be noted that the thread distribution on the lead screw 18 is only located above the side wall of the lead screw 18 to prevent pollen from entering the threaded connection between the lead screw 18 and the inner wall of the sleeve 17, causing the sleeve 17 to be unable to rotate.

[0033] In this embodiment, when the slide plate 11 slides up and down, the lead screw 18 fixedly connected to the upper end of the slide plate 11 is driven to move up and down, and then the sleeve 17 screwed to the side wall of the lead screw 18 is driven to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com