Counterweight traction tensioning wheel structure and stock line traction main machine

A tensioner and counterweight technology, applied in applications, animal feeding devices, poultry industry, etc., can solve problems such as difficulty in replacing the main engine tension spring and inability to adjust the tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

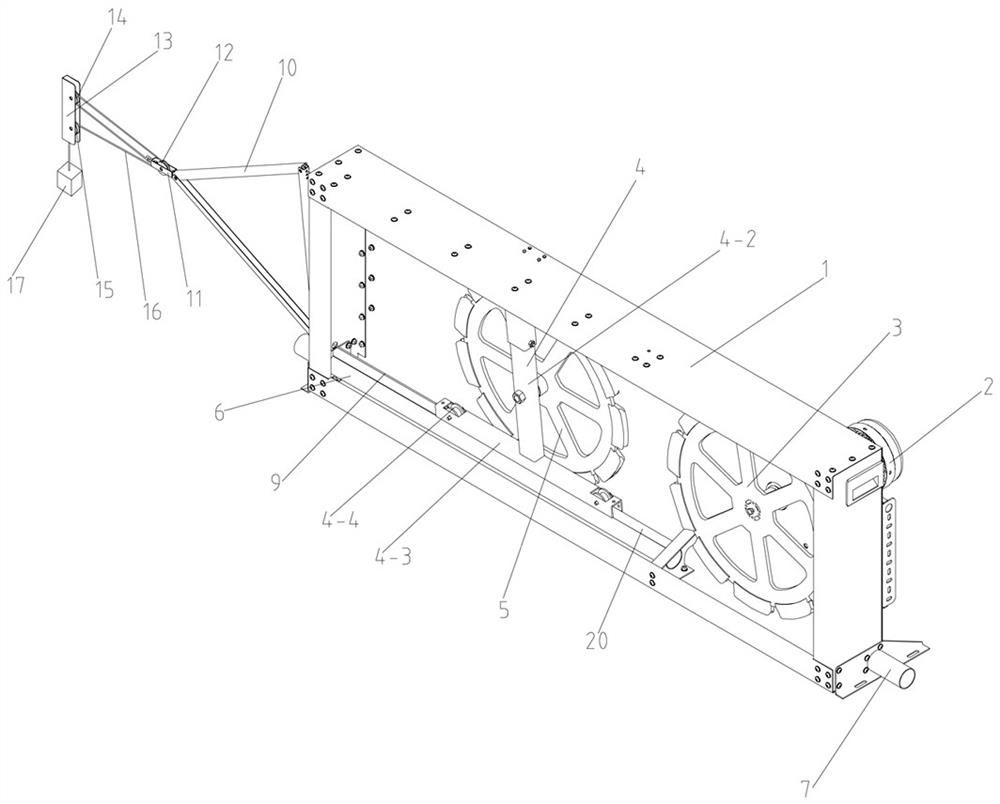

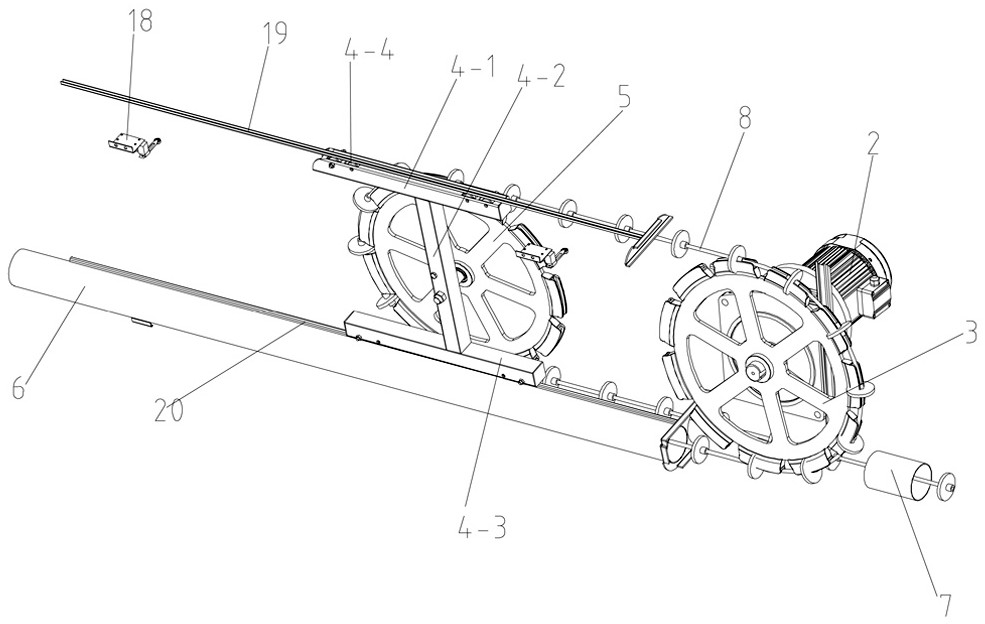

[0020] Such as figure 1 , figure 2 As shown, the counterweight traction tensioner structure of the present invention comprises an upper guide rail 19 and a lower guide rail 20 installed in the housing 1 of the main engine, a slide frame 4 is installed between the upper guide rail 19 and the lower guide rail 20, and the slide frame 4 is equipped with a driven wheel 5, and a connecting rope 9 is installed on the sliding frame 4. The connecting rope 9 extends out of the housing 1, and a counterweight adjustment mechanism is installed outside the housing 1. The connecting rope 9 and the counterweight adjusting mechanism connected.

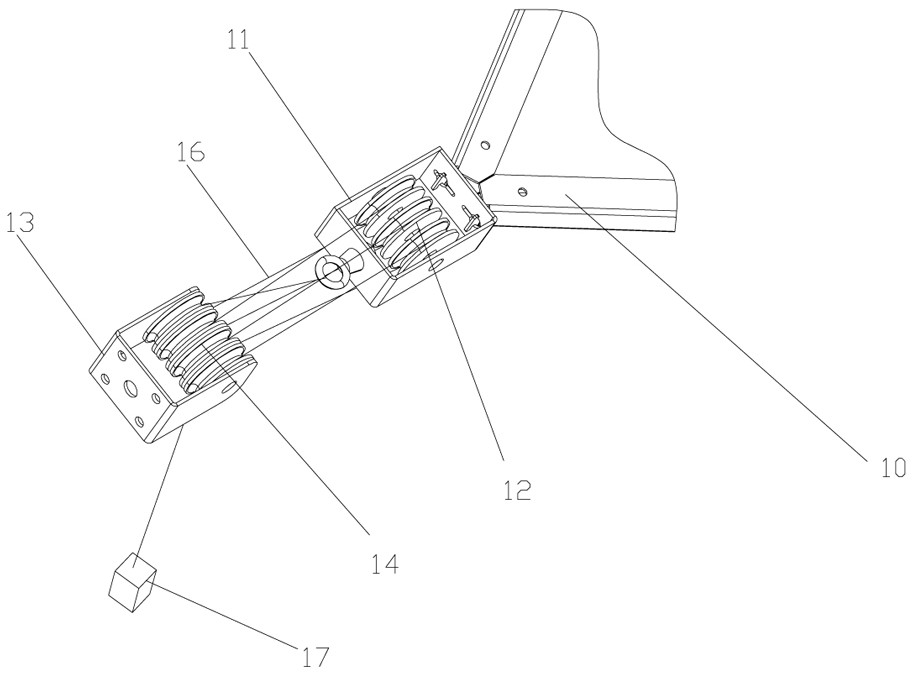

[0021] Wherein, the counterweight adjustment mechanism includes a pulley block, a suspension rope 16 and a counterweight 17, the suspension rope 16 bypasses the pulley block and one end is connected with the counterweight 17, and the other end of the suspension rope 16 is directly or indirectly connected with the connecting rope 9. The counterweight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com