Auxiliary mulling device for improving water resistance of polyurethane material

A polyurethane material and water resistance technology, which is applied in the field of auxiliary kneading devices for improving water resistance of polyurethane materials, and can solve the problems of difficulty in achieving uniform mixing, labor consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

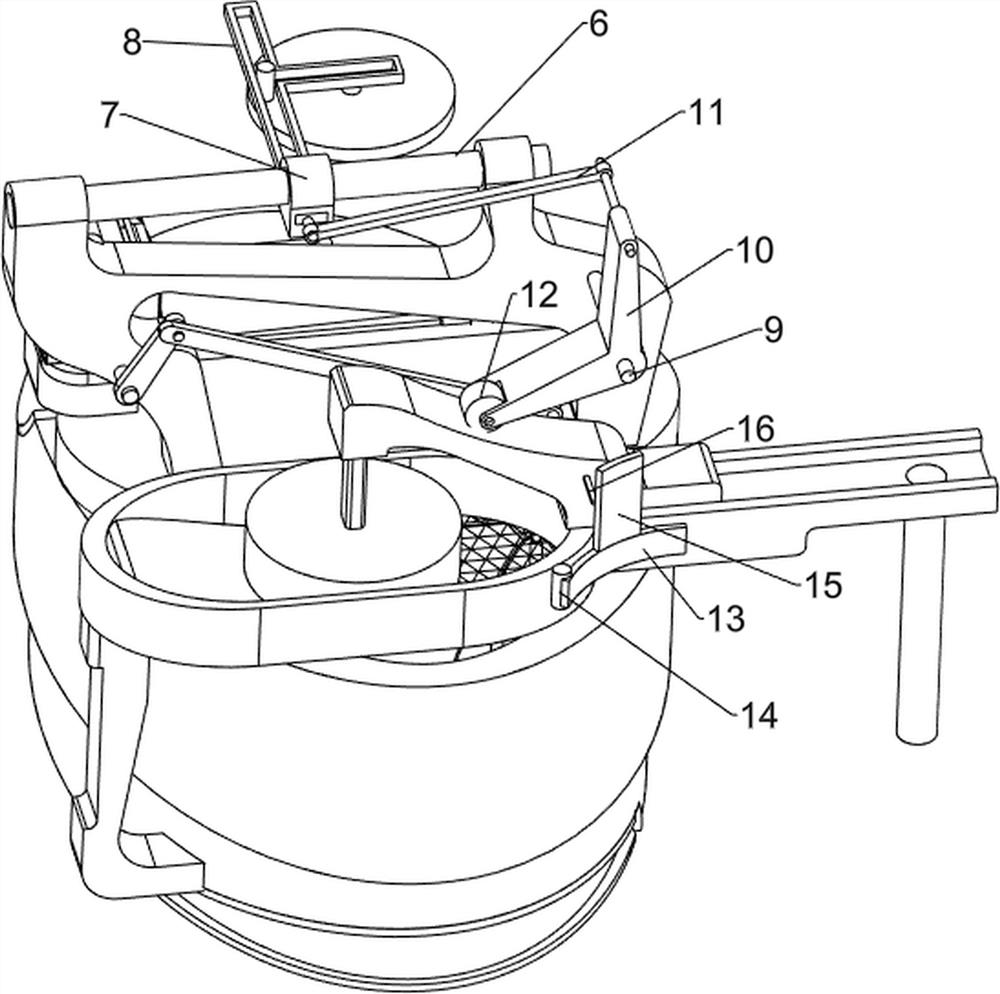

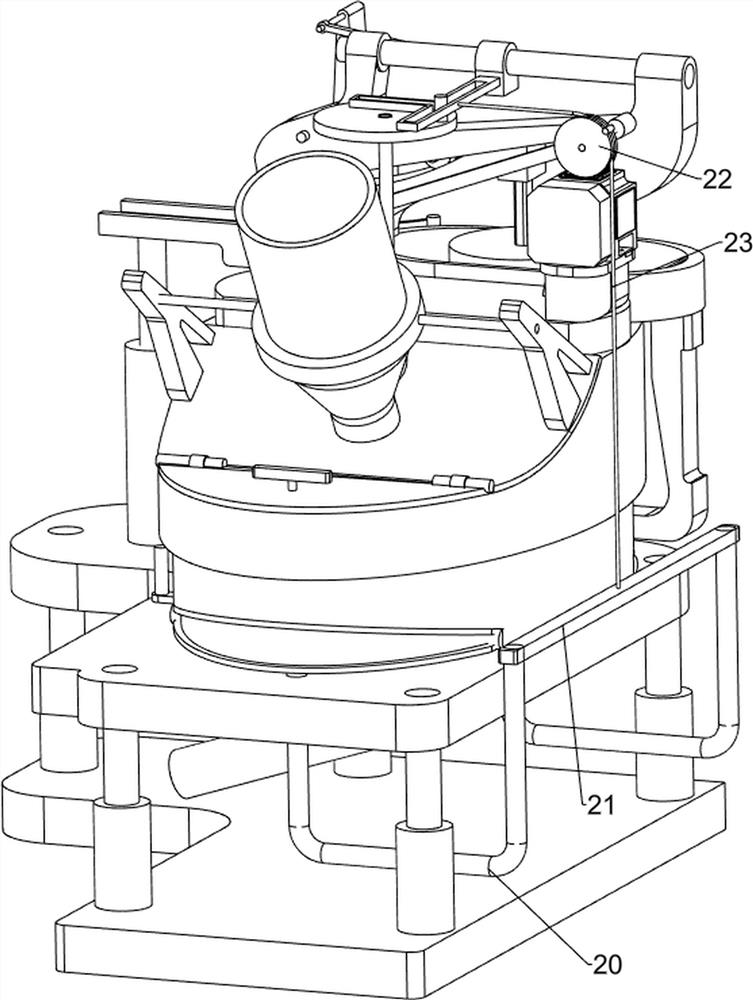

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an auxiliary kneading device for improving the water resistance of polyurethane materials includes a base 1, a workbench 2, a mixer 3, a stirring device 4 and a grinding device 5. A workbench 2 is arranged on the top of the base 1, and on the workbench 2 A mixer 3 is provided, a stirring device 4 is arranged in the mixer 3 , and a grinding device 5 is arranged on the top of the mixer 3 .

[0028] The mixer 3 includes a mixing box 301, a rotating support plate 302, a folding plate 303, a discharge pipe 304, a valve 305, a case cover 306, a first mounting frame 307 and a feeding cylinder 308, and the top of the workbench 2 is provided with a mixer. Material box 301, the left and right sides of the bottom of the mixing box 301 have inclined cavities, and the bottom of the mixing box 301 is symmetrically rotated on both sides to be provided with a rotating support plate 302, between the rotating support plat...

Embodiment 2

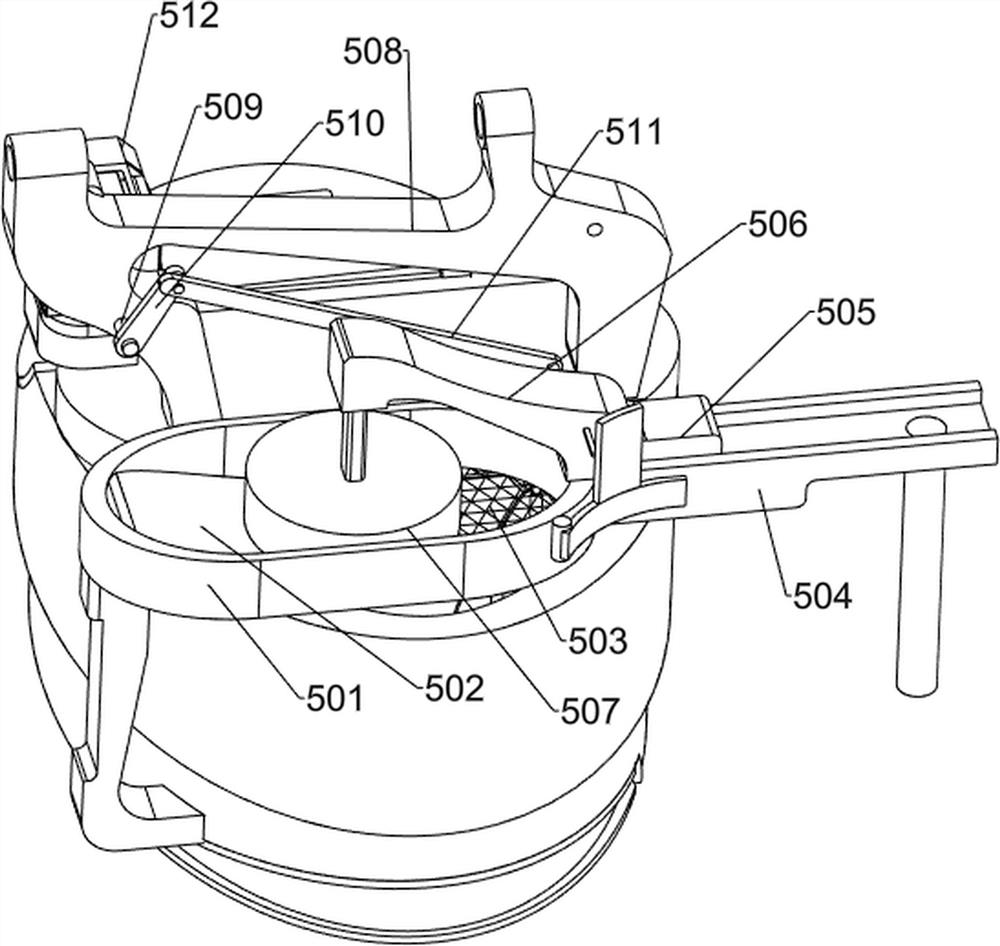

[0033] Such as Figure 5 and Figure 6 As shown, on the basis of Embodiment 1, it also includes a guide rod 6, a guide block 7, a groove plate 8, a fixed shaft 9, a swing rod 10, a connecting rod 11 and a roller 12, and a guide is provided between the tops of the fixed frame 508. The rod 6 is slidably provided with a guide block 7 on the guide rod 6, the guide block 7 is provided with a groove plate 8, the chute of the groove plate 8 is slidably connected with the rocking bar 406, and the front side of the fixed frame 508 is provided with a fixed shaft 9, The left end of the fixed shaft 9 is rotatably provided with a swing rod 10, a torsion spring is arranged between the swing rod 10 and the fixed shaft 9, and the upper part of the swing rod 10 is rotatably provided with a connecting rod 11, and the other end of the connecting rod 11 is rotatably connected with the guide block 7. The other end of the swing lever 10 is rotatably provided with a roller 12 , and the roller 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com