Medical medicine bottle manufacturing equipment

A technology for manufacturing equipment and medicine bottles, which is applied to the special transmission machinery and blowing heads of glass blowing machines, and can solve the problems of large labor burden, low work efficiency and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

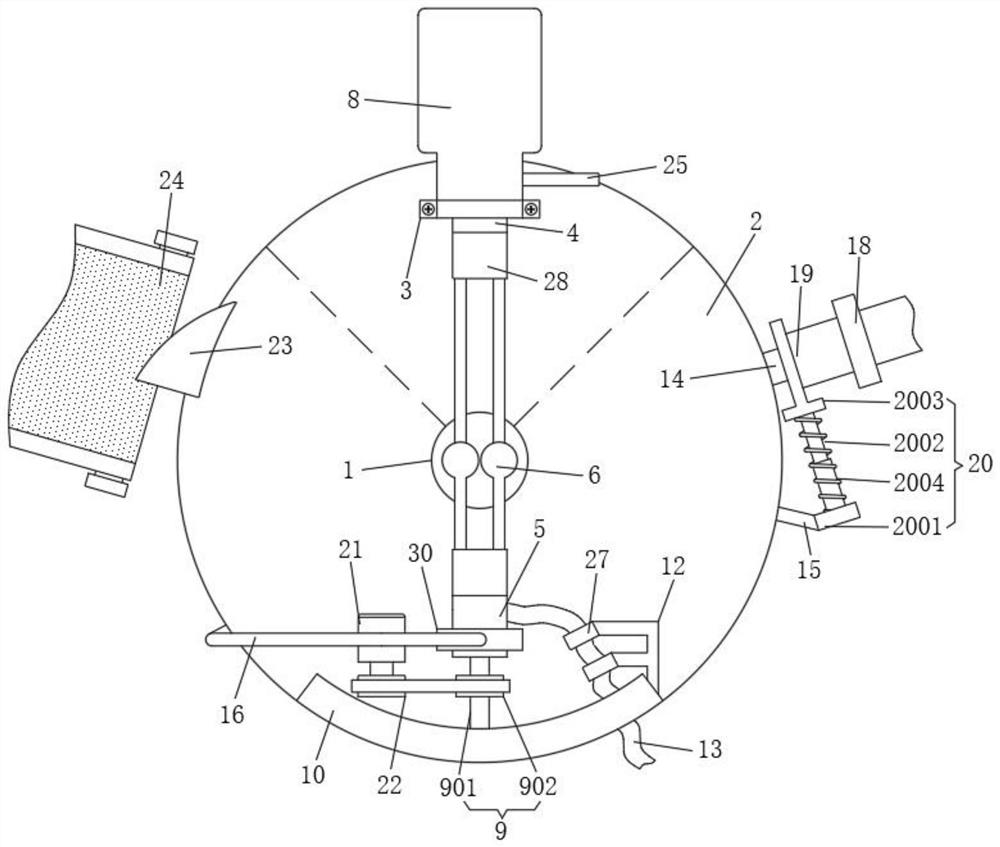

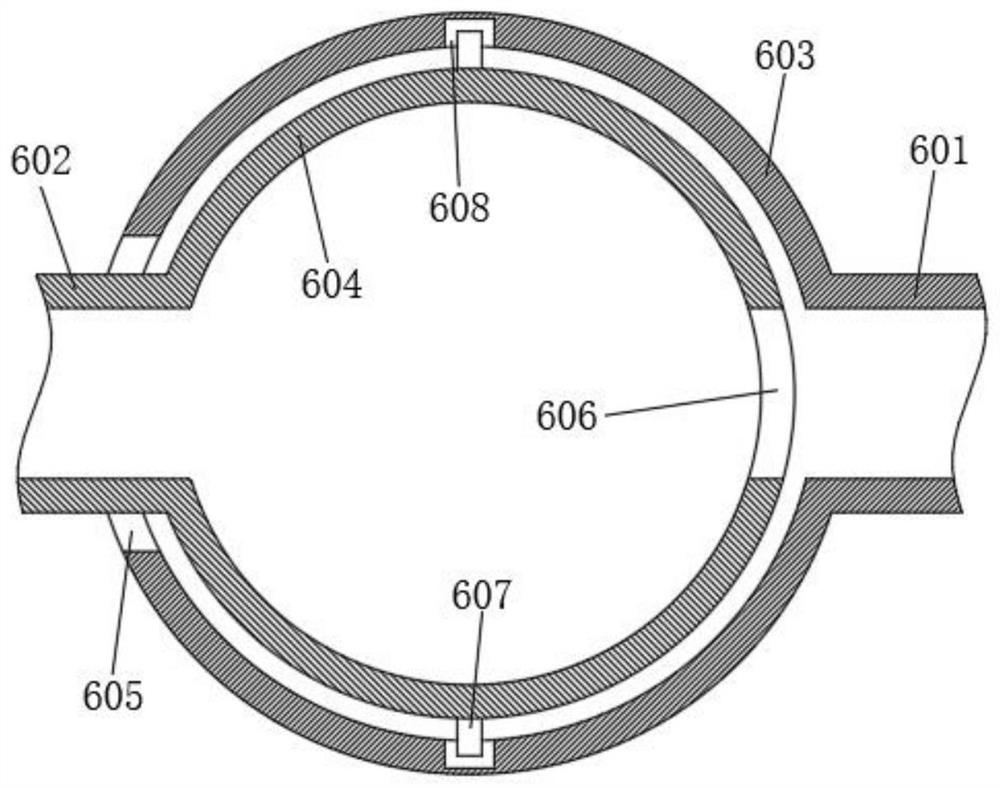

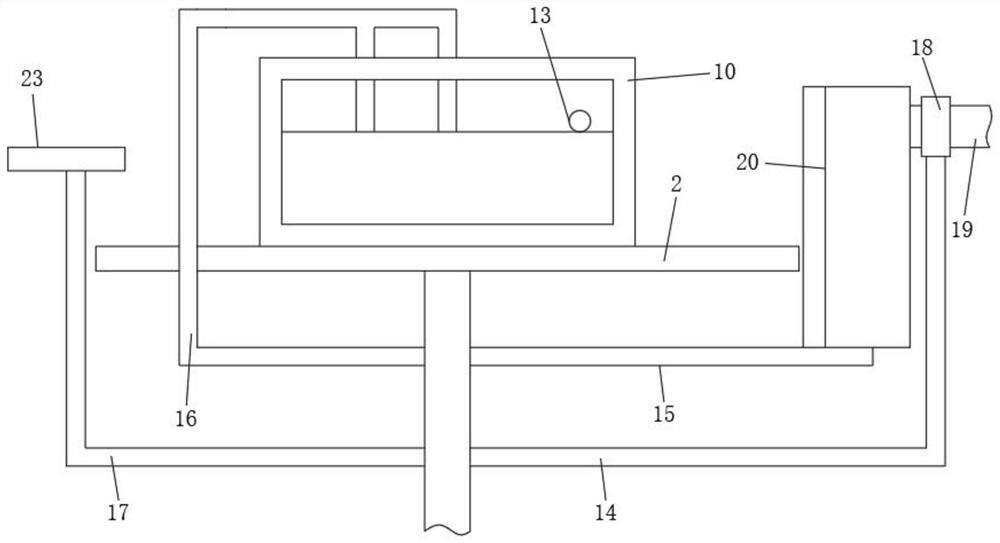

[0035] like Figure 1-9As shown, the embodiment of the present invention provides a medical bottle manufacturing equipment, including a pillar 1 and a transmission mechanism 24, the top of the pillar 1 is rotatably mounted with a disk 2, and the upper surface of the disk 2 is fixedly mounted with a base 3 and a housing 10 , the inside of the housing 10 is provided with a moving assembly 11, the inside of the base 3 is rotatably installed with a first sleeve 4, the side of the first sleeve 4 away from the housing 10 is fixedly installed with an interface 7, and the surface of the base 3 is located at the interface The top of 7 is fixedly installed with mold 8, the outer surface of pillar 1 is fixedly installed with second bracket 14, the third bracket 15, the fourth bracket 16 and the fifth bracket 17, and the top of second bracket 14 is fixedly installed with first collar 18. A feed pipe 19 is fixedly installed inside the first collar 18, a telescopic assembly 20 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com