System and method for judging whether DPF device is close to full load or not so as to achieve timely start regeneration

A DPF and duration technology, applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, noise reduction devices, etc., can solve problems such as inaccurate carbon load, burning out DPF devices, overheating risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

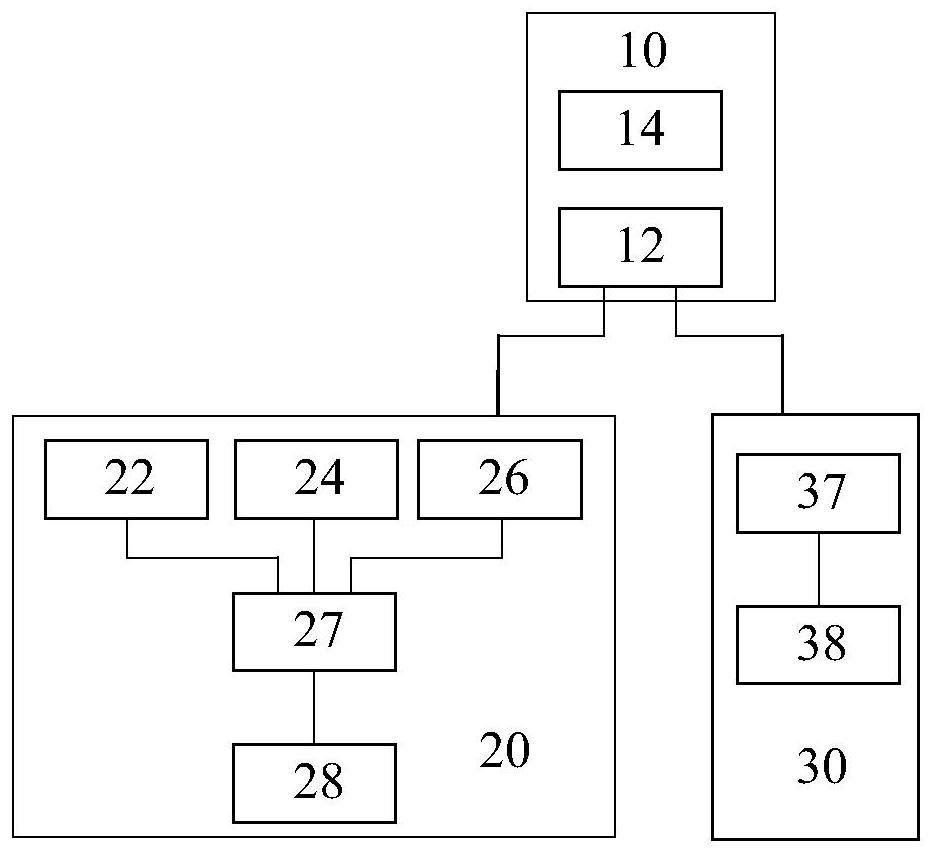

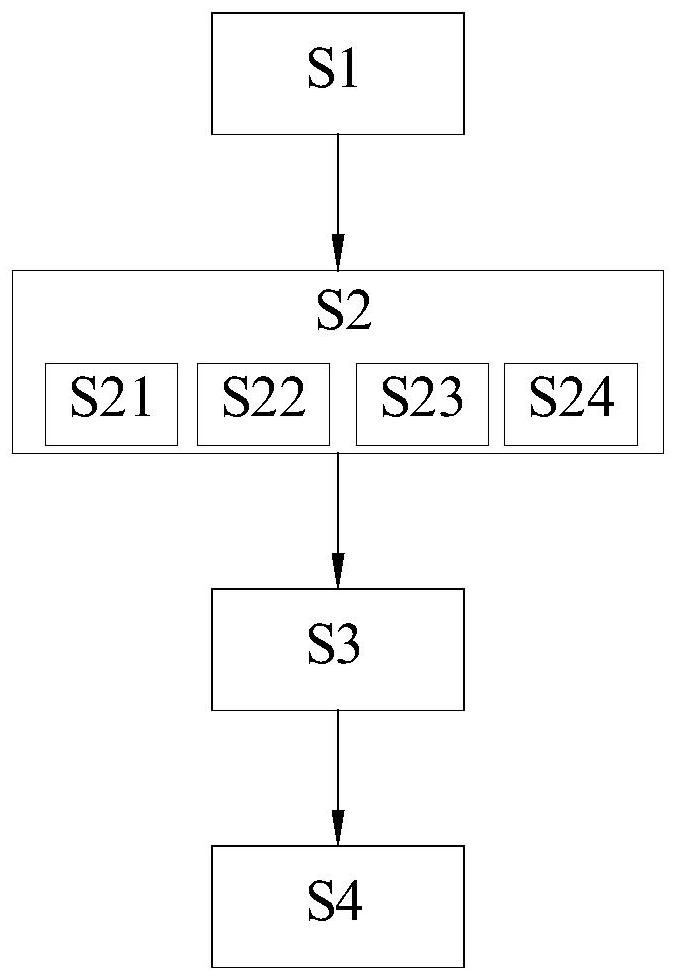

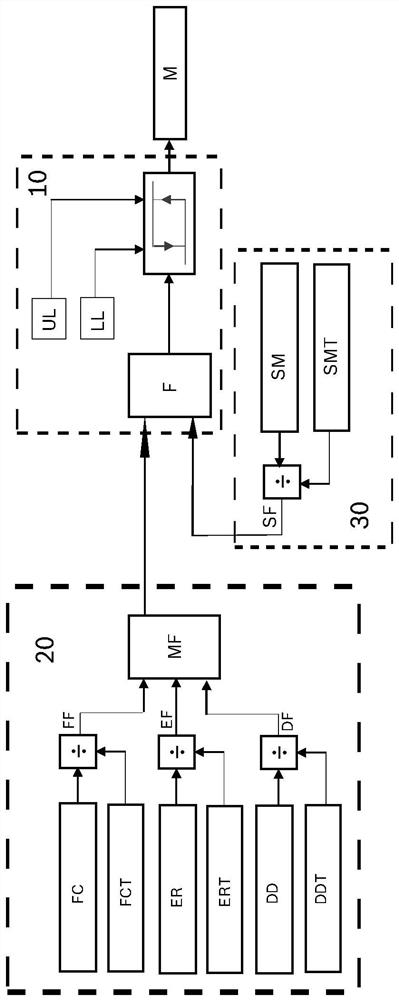

[0035] figure 1 shows a schematic block diagram of the system of the present application; figure 2 A schematic diagram of the application is shown. The system of the present application is used to judge whether the DPF device configured in the exhaust aftertreatment system of the vehicle engine is close to full load, so as to remind the user or driver to trigger regeneration in time. The system according to the present application may be integrated into, provided as part of, an electronic control unit (ECU) of a vehicle engine. Alternatively, the system of the present application may be provided separately.

[0036] combine figure 1 and 2 , the system of the present application includes a general control unit 10 , an optimal prevention module 20 and a basic prevention module 30 . The overall control unit 10 may include an optimization prevention module selector 12 configured to selectively enable or disable the optimization prevention module 20 .

[0037] The optimizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com