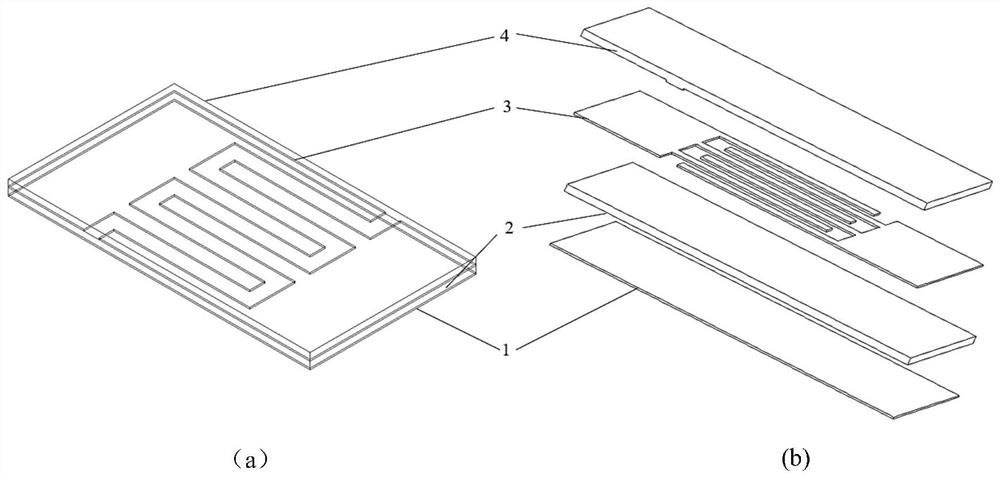

Multifunctional planar capacitive flexible sensor and preparation method thereof

A flexible sensor and capacitive technology, which can be used in instruments, scientific instruments, electric/magnetic exploration, etc., can solve problems such as expensive preparation costs, poor structural design, and sudden drop in sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] see Figure 6 , the present invention also provides a kind of preparation method of multifunctional planar capacitive flexible sensor, and described preparation method mainly comprises the following steps:

[0048] S1. Preparation of PDMS prepolymer: select PDMS monomer, mix it with curing agent evenly at a ratio of 10:1, manually stir in a beaker for 10min-20min, and place it in vacuum for 30min-60min after stirring to remove air bubbles;

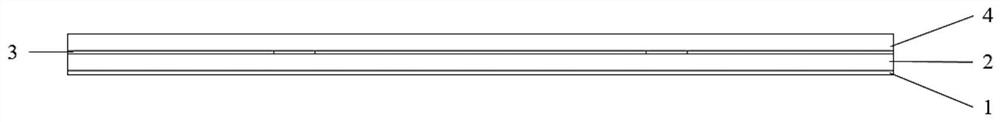

[0049] S2. Prepare the sensor base layer: select a glass slide with a thickness of 1 mm to 2 mm as the hard base, and use a glue homogenizer on the hard base at a speed of 300 r / min to 500 r / min, at a speed of 100 rpm / s to 150 rpm / s. Accelerate the spin coating of PDMS prepolymer for 60s to 90s; then use a hot plate to heat the PDMS prepolymer at a temperature of 85°C to 90°C for 2h to 3h to solidify, and peel off the PDMS prepolymer film from the hard substrate;

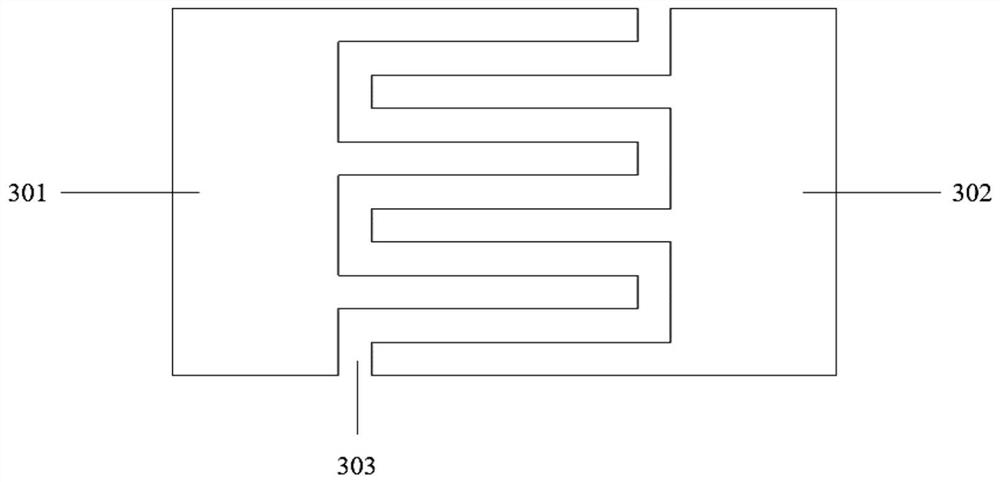

[0050] S3, prepare the sensor electrode layer: select the upper sur...

Embodiment 1

[0057] The preparation method of the multifunctional planar capacitive flexible sensor provided in Embodiment 1 of the present invention mainly includes the following steps:

[0058] S1. Preparation of PDMS prepolymer: Select PDMS monomer, mix it with curing agent evenly at a ratio of 10:1, manually stir in a beaker for 10 minutes, and place it in vacuum for 30 minutes after stirring to remove air bubbles;

[0059] S2, preparing the sensor base layer: select a glass slide with a thickness of 1 mm as the hard base, and use a coater to spin-coat the PDMS prepolymer on the hard base at a speed of 300r / min and an acceleration of 100rpm / s for 90s; after that Use a hot plate to heat the PDMS prepolymer at a temperature of 85°C for 3 hours to solidify it, and peel off the PDMS prepolymer film from the hard substrate, and the thickness of the obtained substrate layer is 0.3mm;

[0060] S3, prepare the sensor electrode layer: select the upper surface of the sensor base layer, and trans...

Embodiment 2

[0066] The preparation method of the multifunctional planar capacitive flexible sensor provided in Embodiment 2 of the present invention mainly includes the following steps:

[0067] S1. Preparation of PDMS prepolymer: select PDMS monomer, mix it with curing agent evenly at a ratio of 10:1, manually stir in a beaker for 15 minutes, and place it in vacuum for 40 minutes after stirring to remove air bubbles;

[0068] S2, preparing the sensor base layer: select a glass slide with a thickness of 1 mm as the hard base, and use a glue spreader to spin-coat the PDMS prepolymer on the hard base at a speed of 400r / min and an acceleration of 100rpm / s for 80s; after that Use a hot plate to heat the PDMS prepolymer at a temperature of 90°C for 2 hours to solidify it, and peel off the PDMS prepolymer film from the hard substrate, and the thickness of the obtained substrate layer is 0.4mm;

[0069] S3, prepare the sensor electrode layer: select the upper surface of the sensor base layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com