High-sensitivity optical fiber grating liquid level/fluid pressure sensor

A fiber grating and high-sensitivity technology, which is used in the measurement of fluid pressure, fluid pressure measurement using optical methods, liquid/fluid solid measurement, etc., can solve the problems of difficult liquid level monitoring and limited sensitivity, and achieve easy networking, The effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

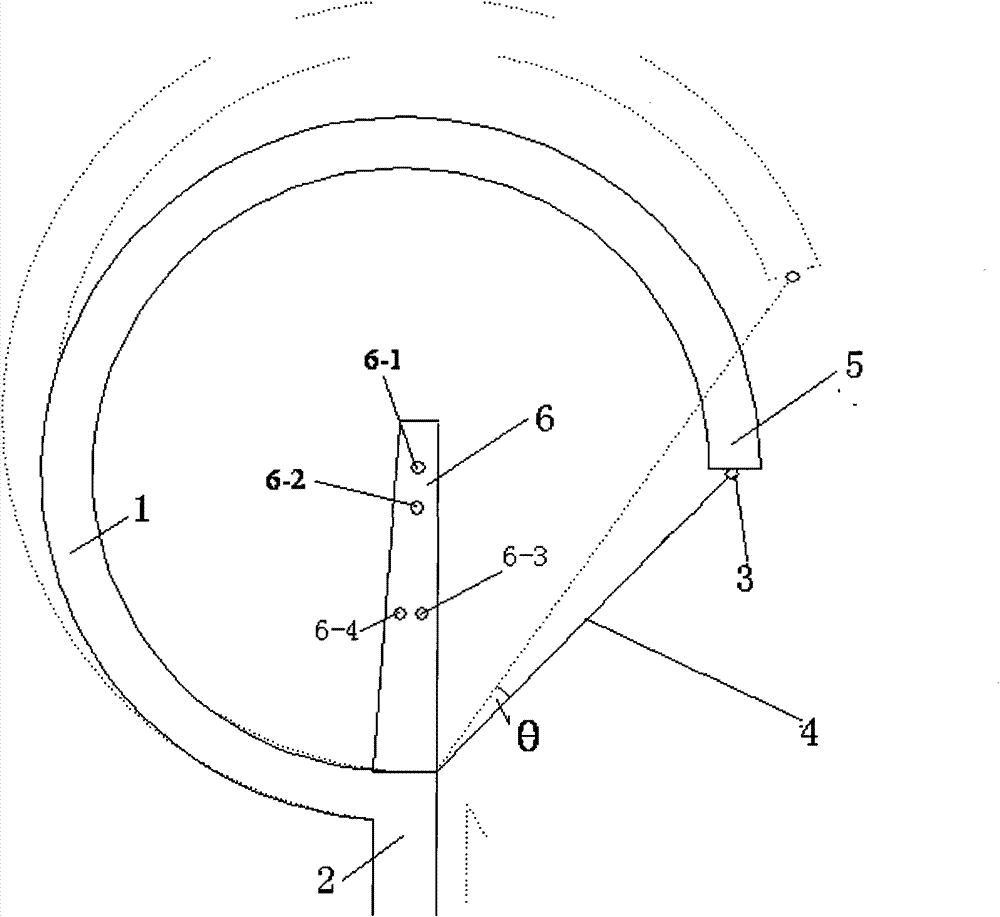

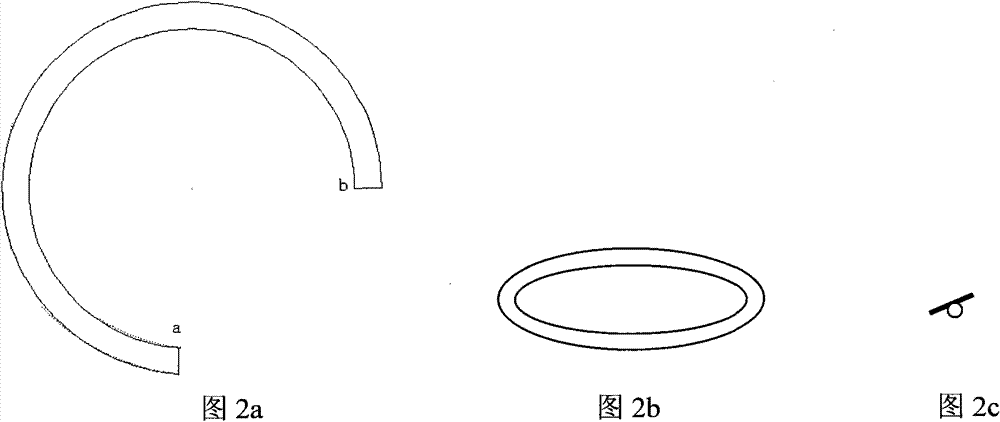

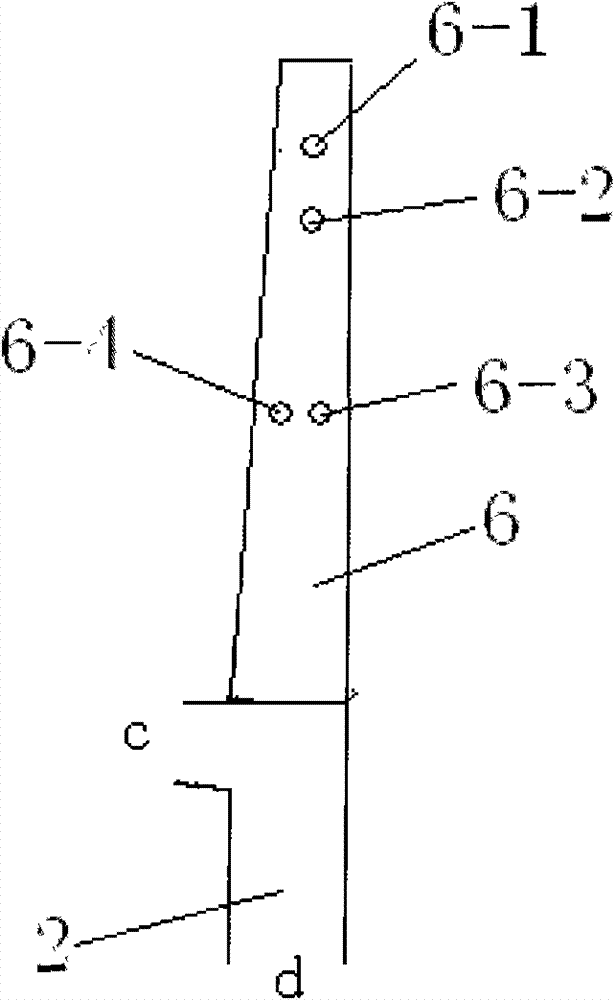

[0029] In the figure: 1. Spring tube, 2. Pressure inlet, 3. Head, 4. Sensing grating and its optical fiber, 5. Free end of spring tube, 6. Expansion frame integrated with pressure inlet 2, 7. Glass cover for encapsulating the shell, 8. Cylindrical appliance for encapsulating the shell, 9. Pressure gauge, 10. Water pipe, 11. Valve, 12. Coupler, 13. Optical fiber where the compensation grating is located, BBS, broadband light source, OSA, spectrometer.

[0030] image 3 6-1~6-4 in the figure are screw holes with a diameter of 2mm.

[0031] Figure 4 8-1 in the figure is a hole slightly larger than the outer diameter of the pressure inlet. When the sensor head is put into the package shell, the pressure inlet needs to pass through this hole. 8-2~8-11 are screw holes with a diameter of 2mm. ; 8-12 is a hole with a diameter of 9mm, which is used to place a small D-type adapter.

[0032] Such as Figure 1 to Figure 6 shown. High-sensitivity fiber grating liquid level / fluid pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com