Variable speed gear fault signal extraction method, diagnosis method and system based on adaptive time-varying comb filtering, and storage medium

A technology of comb filtering and rotating speed signal, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc. It can solve the problems of strong background noise, missed diagnosis, and difficulty in detecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

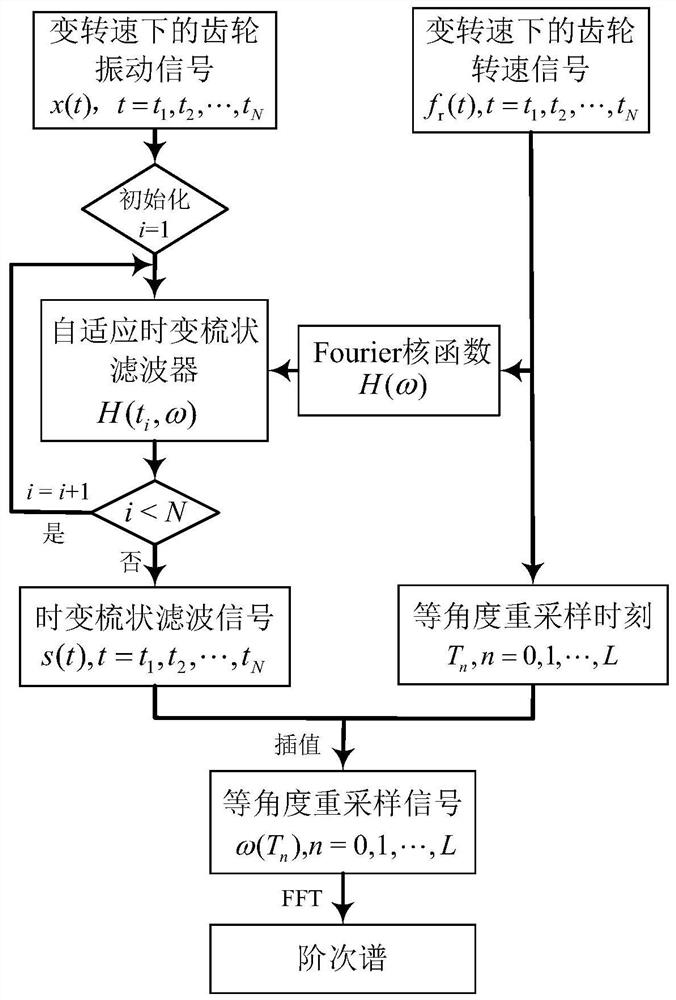

[0069] Such as figure 1 As shown, the present embodiment provides a variable-speed gear fault diagnosis method based on adaptive time-varying comb filtering, including the following steps: (1) collecting gear vibration signals and speed signals at variable speeds; (2) according to the speed Signal design adaptive time-varying comb filter; (3) Adopt adaptive time-varying comb filter to perform time-varying comb filtering on the gear vibration signal to obtain time-varying comb filtering signal; (4) According to the speed signal The time-varying comb filter signal is resampled at equal angles to obtain the resampled signal in the angle domain; (5) The order spectrum is obtained by performing spectrum analysis on the resampled signal in the angle domain, and according to the modulation edge frequency order around the meshing order in the order spectrum Diagnose gear faults at variable speeds for the first time.

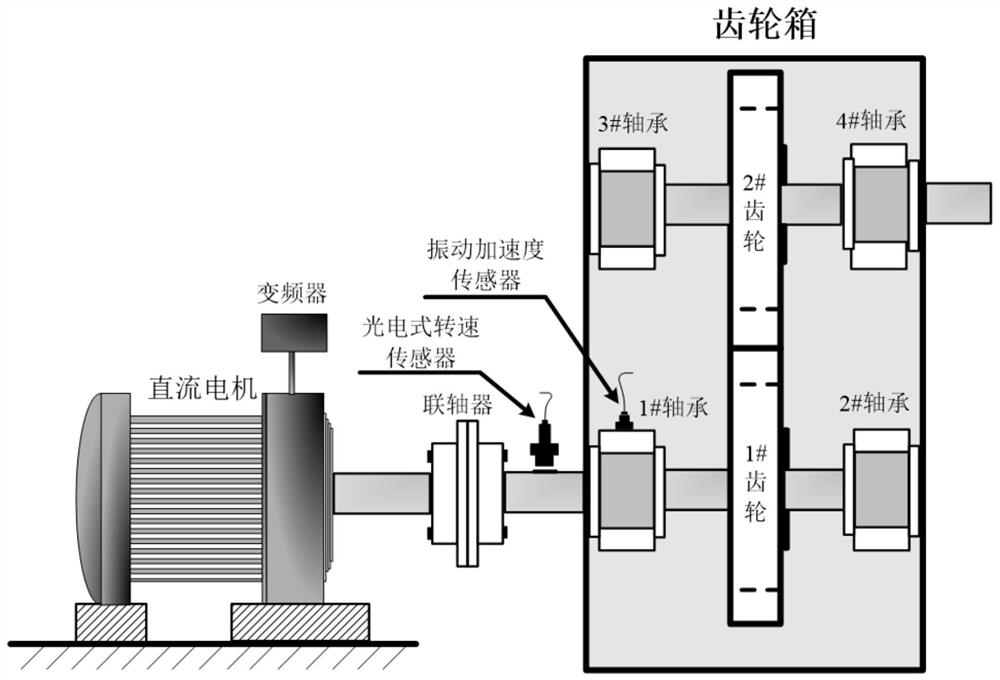

[0070] The test data of this embodiment comes from the single-sta...

Embodiment 2

[0116] This embodiment provides a variable speed gear fault signal extraction method based on adaptive time-varying comb filtering, including the following steps:

[0117] A collects gear vibration signal x(t) and speed signal f at variable speed r (t), t=t 1 ,t 2 ,...,t N ;

[0118] B Use an adaptive time-varying comb filter to perform time-varying comb filtering on the gear vibration signal to obtain a time-varying comb filtering signal. The time-varying comb filtering signal is the purified gear mesh vibration component and its modulation edge frequency components.

[0119] For the structure of the adaptive time-varying comb filter and the process of using the adaptive time-varying comb filter to perform time-varying comb filtering on the gear vibration signal, please refer to the description of Embodiment 1. Let me repeat.

Embodiment 3

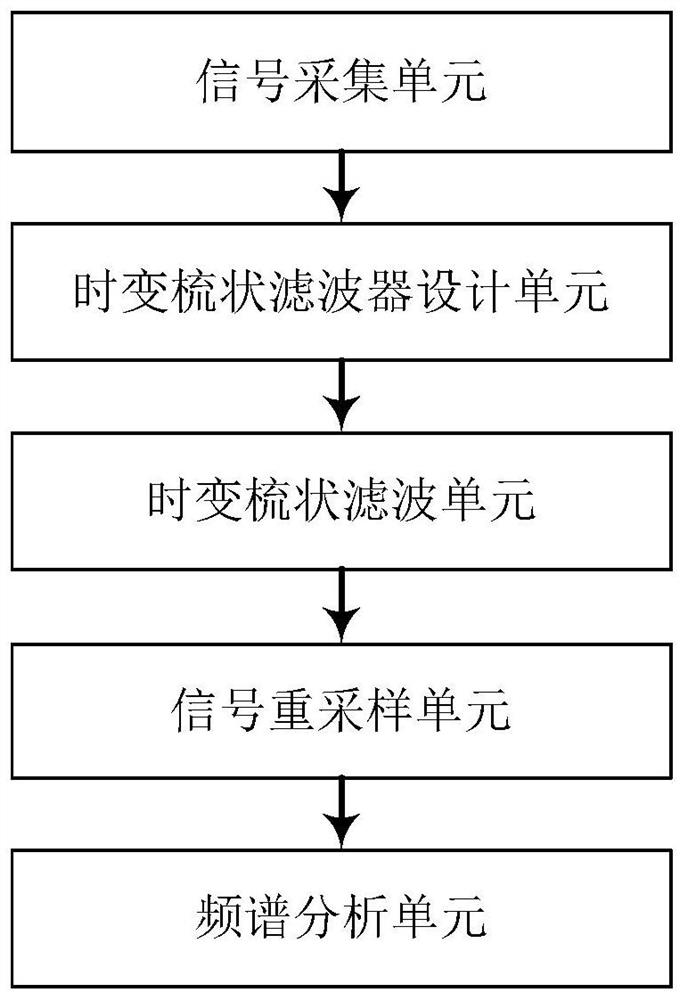

[0121] Such as figure 2 As shown, this embodiment provides a system based on the above-mentioned variable-speed gear fault diagnosis method based on adaptive time-varying comb filtering, including:

[0122] The signal acquisition unit is used to synchronously acquire gear vibration signals and rotational speed signals at variable rotational speeds;

[0123] A time-varying comb filter design unit is used to design a time-varying comb filter according to the collected rotational speed signal.

[0124] A time-varying comb filter unit, configured to perform time-varying filtering on the collected gear vibration signals according to the time-varying comb filter to obtain a time-varying comb filtering signal;

[0125] The signal resampling unit is used to perform equiangular resampling on the time-varying comb filter signal according to the collected rotational speed signal, so as to obtain equiangular resampled signals.

[0126] The spectrum analysis unit is used for performing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com