On-line monitoring device and monitoring method for insulation of wire rod hydroelectric joint of internal water-cooled generator

A technology for water and electricity joints and monitoring devices, which can be used in measuring devices, measuring electricity, measuring electrical variables, etc., and can solve problems such as blind spots, poor insulation resistance R, and poor timeliness of finding problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

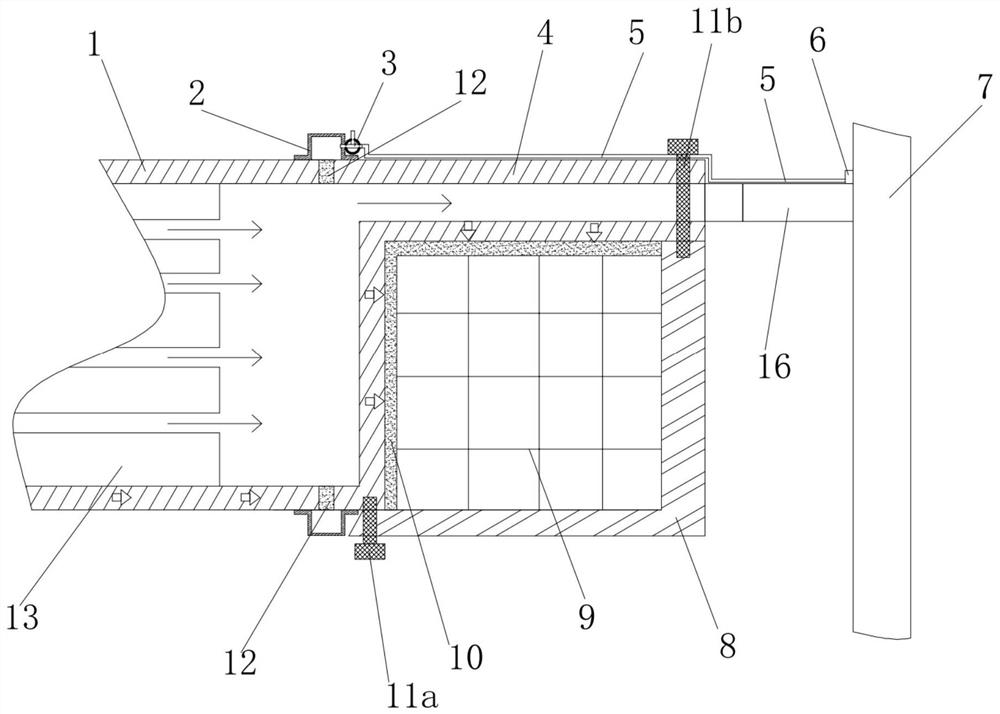

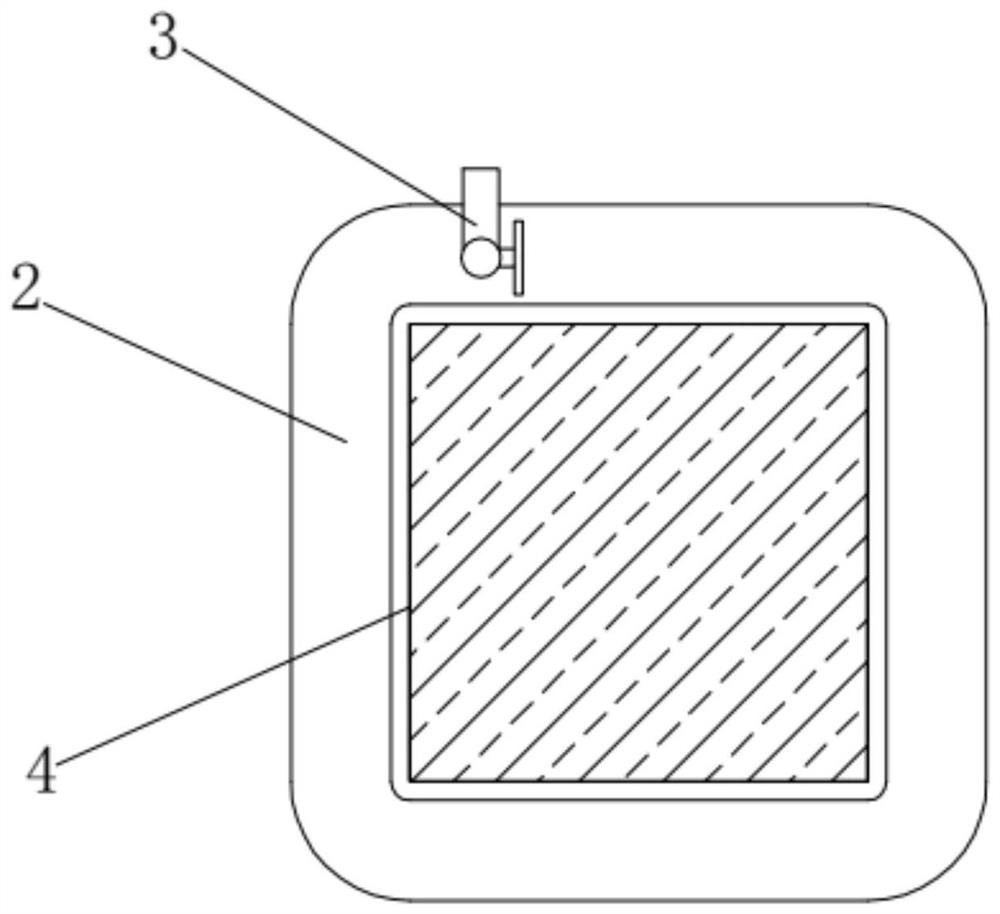

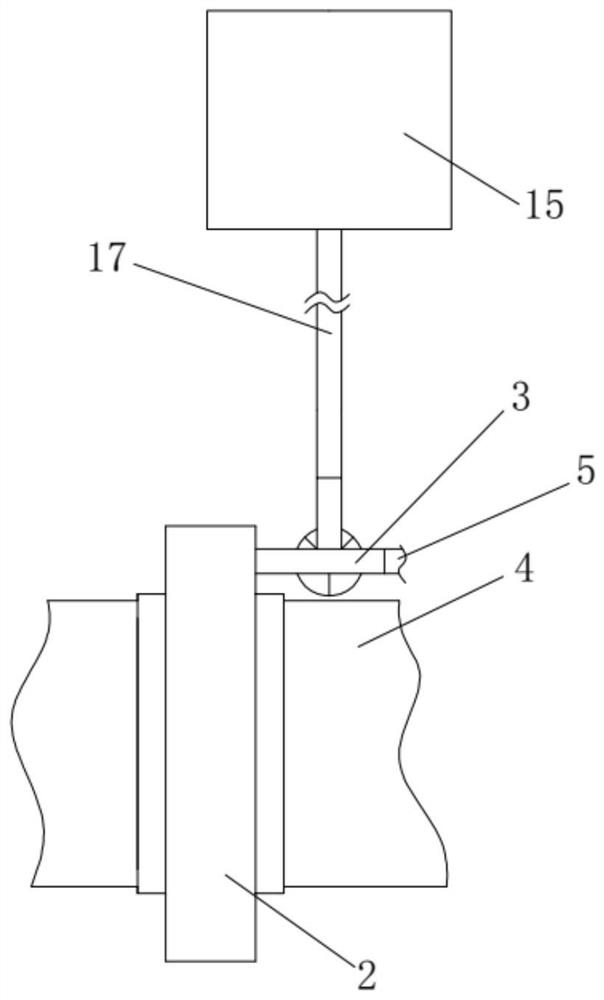

[0033] Depend on Figure 1-5 Given, the present invention water inner cooling generator wire rod hydroelectric connector insulation on-line monitoring device comprises generator wire rod hydroelectric connector, there is weld seam 12 between the water box 1 and the water box cover 4 of the generator wire rod hydroelectric connector, its characteristic The outer side of the weld 12 is provided with a gas detection box 2 arranged along the weld and covering the weld 12. The bottom surface of the gas detection box 2 is sealed and connected with the outer surface of the hydroelectric joint of the generator bar, so that the inner cavity of the gas detection box 2 constitutes A relatively closed tracer gas monitoring space 2a, the entire section of the weld 12 is located within the coverage of the tracer gas monitoring space 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com