Multi-source error analysis method in multi-process mechanical manufacturing process

A technology of mechanical manufacturing and analysis methods, applied in the direction of program control, computer control, general control system, etc., capable of solving problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

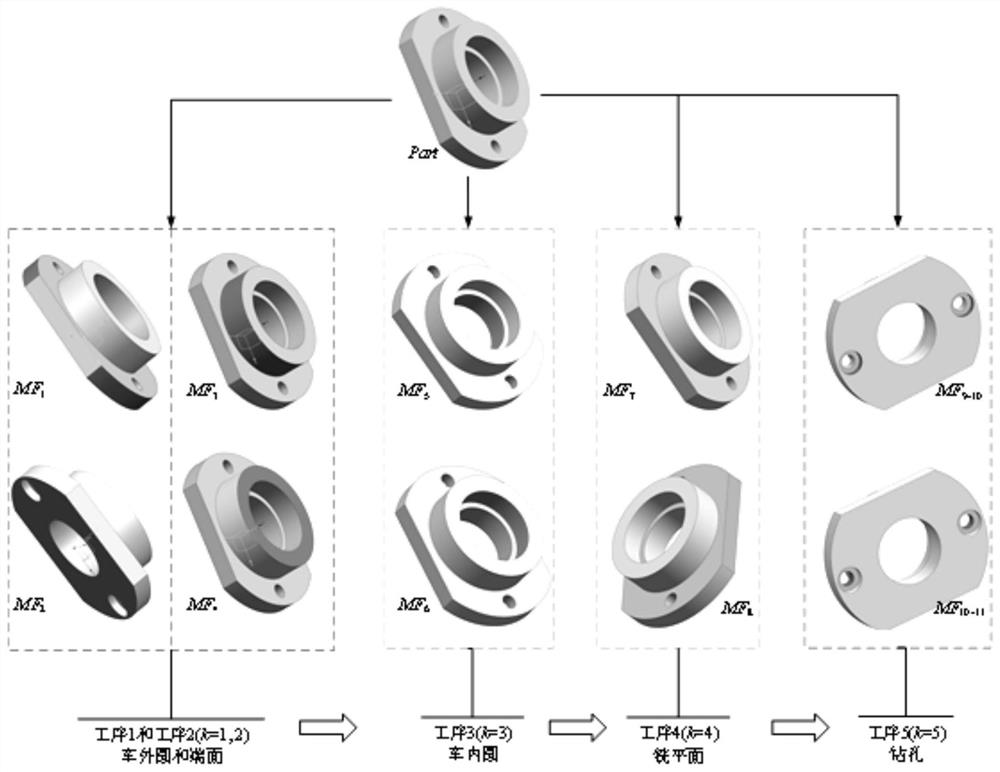

[0041] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

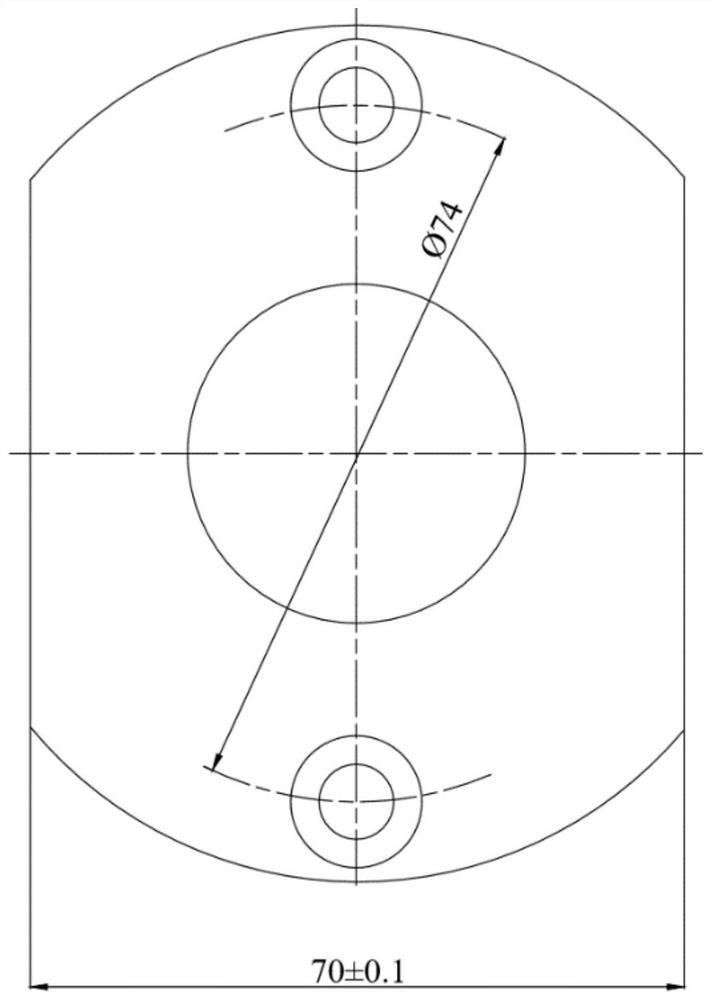

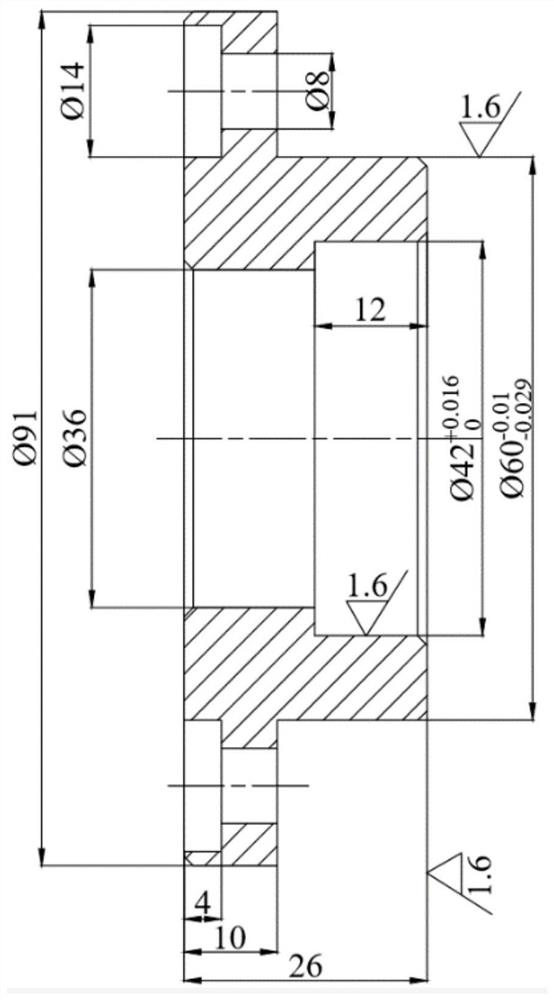

[0042] A method for analyzing multi-source errors in a multi-process mechanical manufacturing process, comprising the following steps:

[0043] Step 1: Multi-source error analysis

[0044] Conduct an inductive analysis of the types of potential errors that may occur in the multi-process complex manufacturing process of mechanical parts, including fixture errors, workpiece positioning errors, tool errors, and process system deformation errors (which are caused by factors such as cutting force and rigidity of the tool), Identify sources of error. Specifically, multi-source error analysis requires testing equipment to measure the actual values of position, size, and geometry, and compare them with theoretical values...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com