Rotating part fault diagnosis model construction method and application

A technology of fault diagnosis model and rotating parts, which is applied in the direction of computer parts, character and pattern recognition, pattern recognition in signals, etc., and can solve the problems of poor accuracy and versatility of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

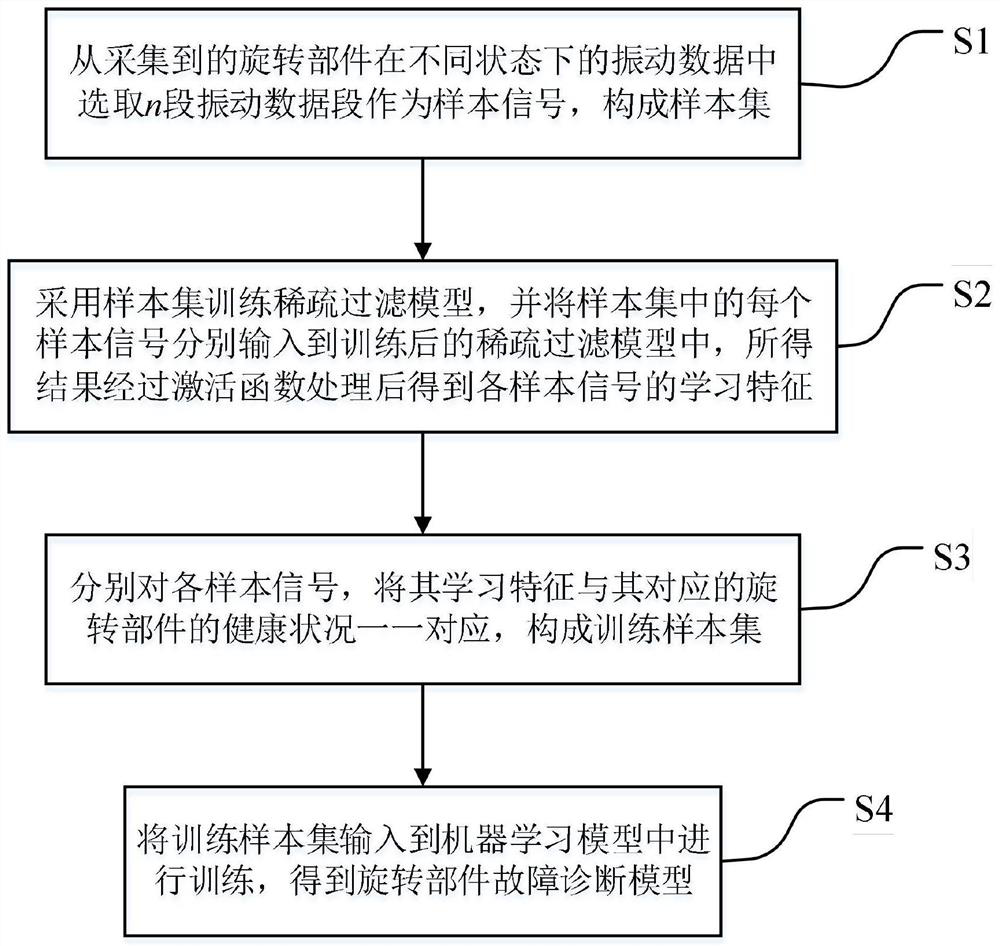

[0046] A method for constructing a motor bearing fault diagnosis model, comprising the following steps:

[0047] S1. Select n sections of vibration data from the collected vibration data of the motor bearing in different states as a sample signal to form a sample set; wherein, n is a positive integer;

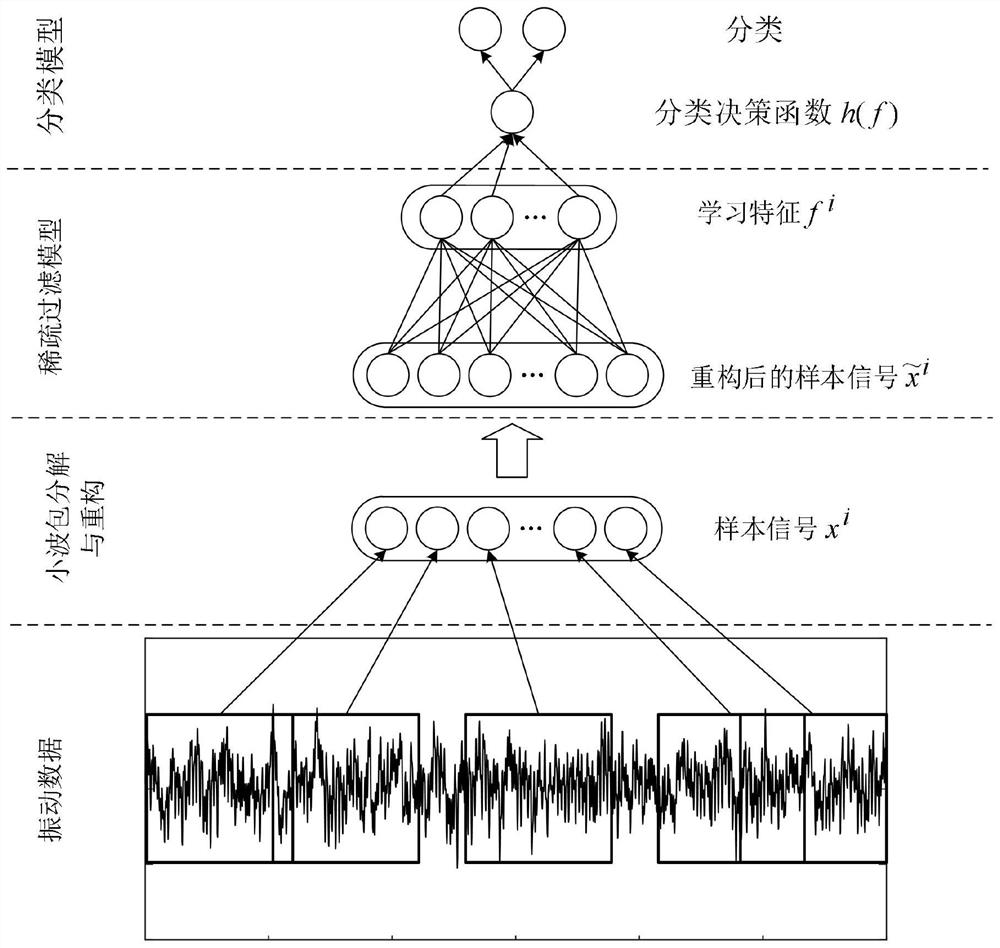

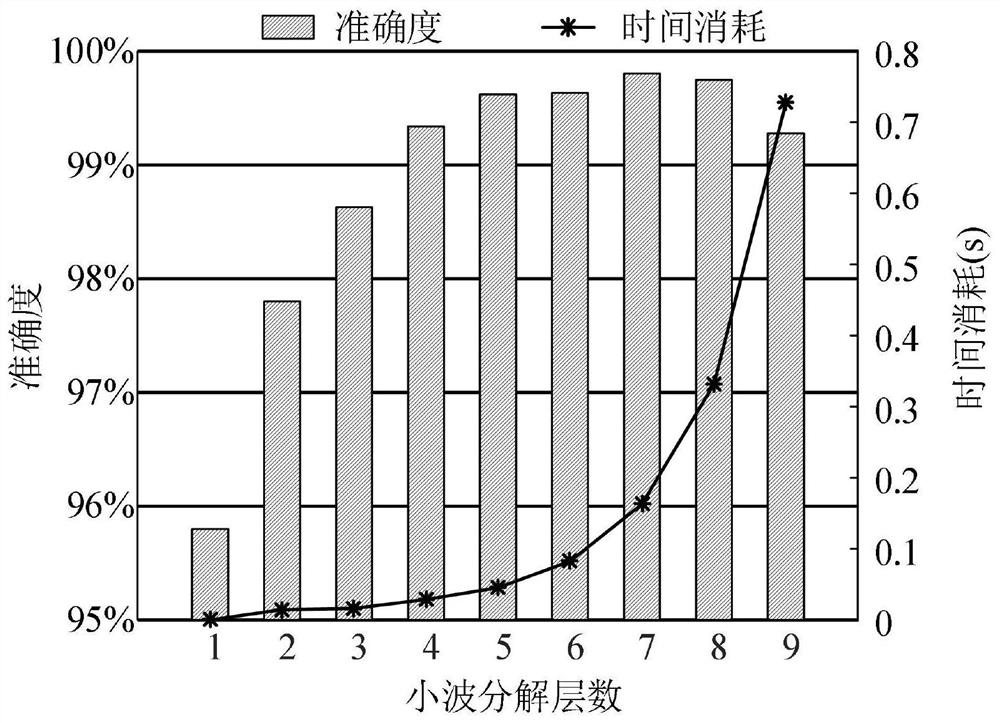

[0048] Specifically, in this embodiment, from the collected vibration data of motor bearings in different states, n segments are randomly selected with a length of N in The vibration data segment is used as a sample signal; the motor bearing vibration data released by Casey Western Reserve University is used as a vibration data set. Vibration signals were collected from the motor drive end of the test setup under four fault conditions: normal, outer race fault (OF), inner race fault (IF) and ball fault (RF). For the three fault conditions of outer ring fault, inner ring fault and ball fault, vibration signals under three different fault severity levels with fault radii of 0.18...

Embodiment 2

[0072] A method for diagnosing a motor bearing fault, comprising:

[0073] Input the vibration data of the motor bearing in the current state into the motor bearing fault diagnosis model constructed by using the motor bearing fault diagnosis model construction method provided in Embodiment 1 of the present invention to obtain the motor bearing fault status.

[0074] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0076] A machine-readable storage medium, the machine-readable storage medium stores machine-executable instructions, and when the machine-executable instructions are called and executed by a processor, the machine-executable instructions cause the processor to implement the following: The motor bearing fault diagnosis model construction method described in Embodiment 1 and / or the motor bearing fault diagnosis method described in Embodiment 2.

[0077] The relevant technical solutions are the same as those in Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com