Fuel cell temperature control system compatible with different power stacks

A temperature control system and temperature control technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of large temperature fluctuation, small test range, complex structure of the heat dissipation system, etc., and achieve the speed of heat dissipation response. Fast, simple and compact structure, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

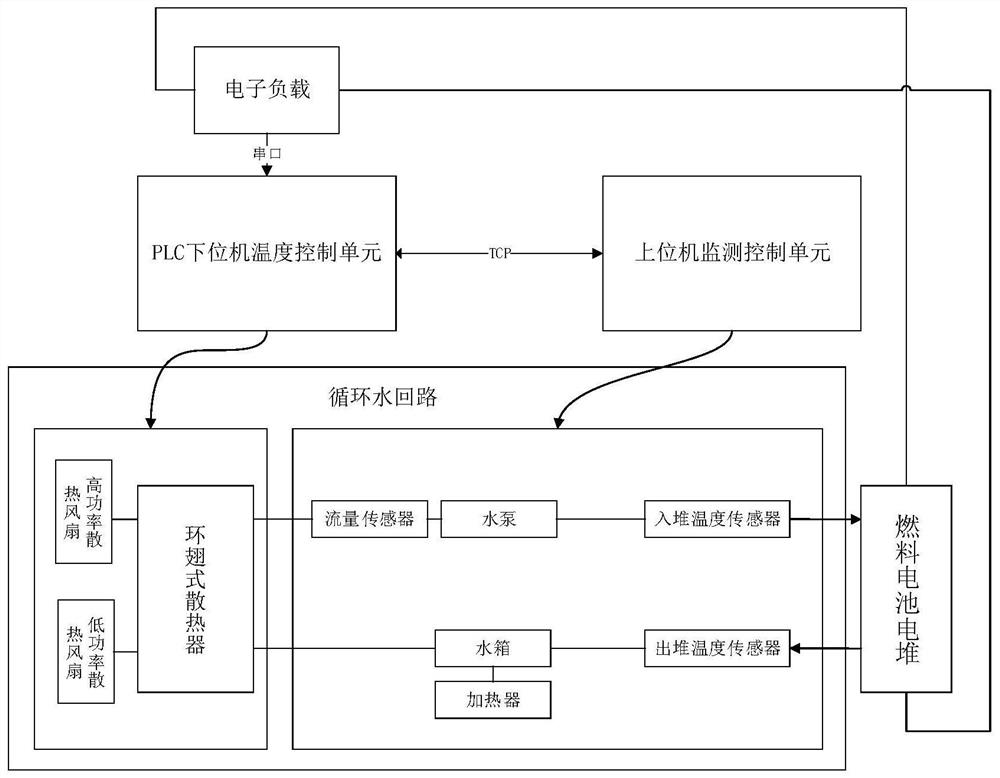

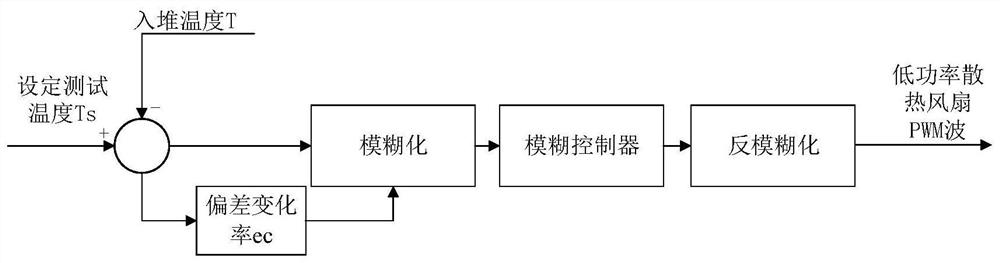

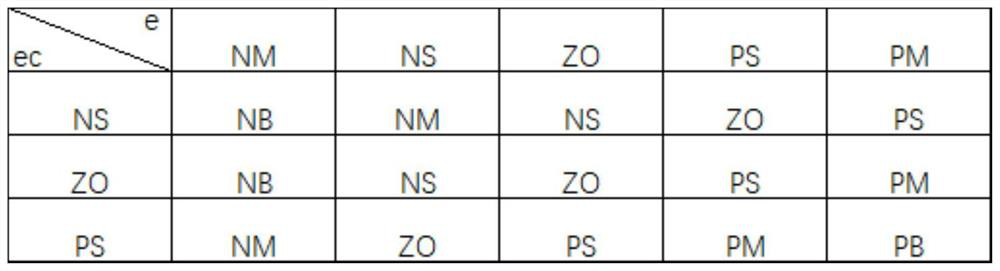

[0034] This embodiment proposes a fuel cell temperature control system compatible with different power stacks, such as figure 1 As shown, it includes a PLC lower computer temperature control unit, an upper computer monitoring control unit, a circulating water circuit and an electronic load; the circulating water circuit includes circulating water, a stack-in temperature sensor, a stack-out temperature sensor, a water tank, a water pump, a flow sensor, Heater, ring fin radiator, high power cooling fan and low power cooling fan;

[0035] The temperature control unit of the PLC lower computer is used to monitor the detection information of the stack-in temperature sensor, the stack-out temperature sensor and the flow sensor, and the electronic load power, and based on the detection information and the electronic load power, control the heater, high-power cooling fan and The working state of the low-power cooling fan realizes the control of the temperature of the fuel cell; the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com