Spallation neutron target with mixed cooling flow channel

A technology of spallation neutron target and mixed cooling, which is applied in neutron source, target for producing nuclear reaction, DC voltage accelerator, etc. Cooling fluid and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

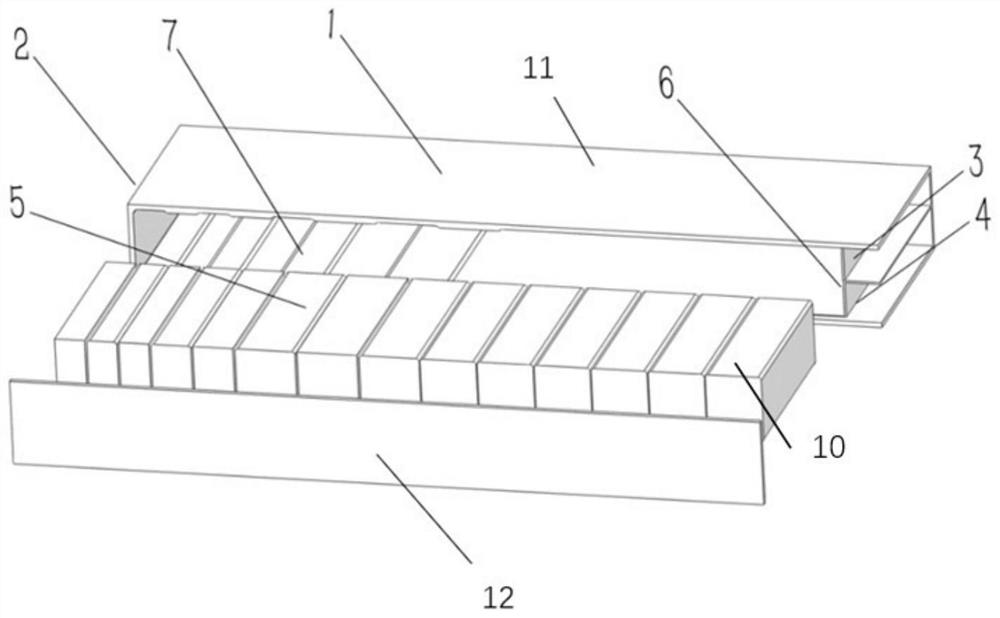

[0036] Example: a tungsten target consisting of 14 target pieces

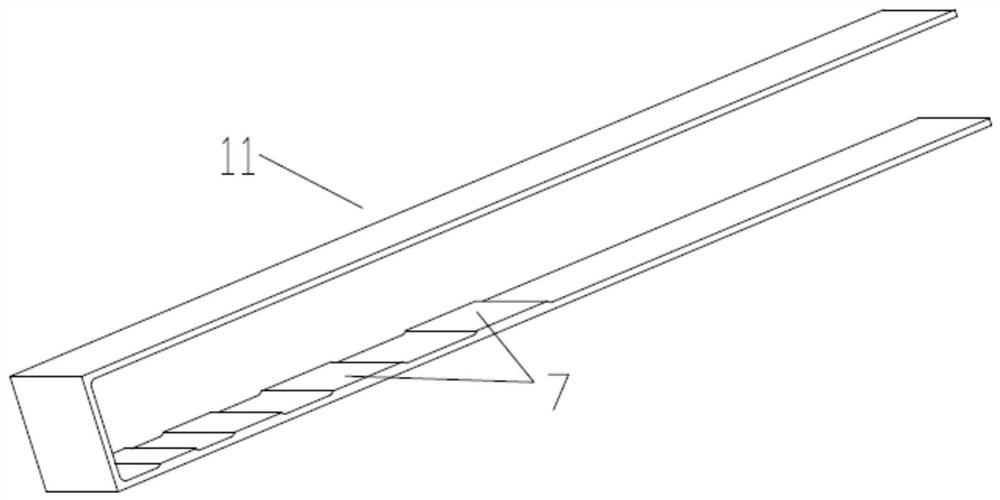

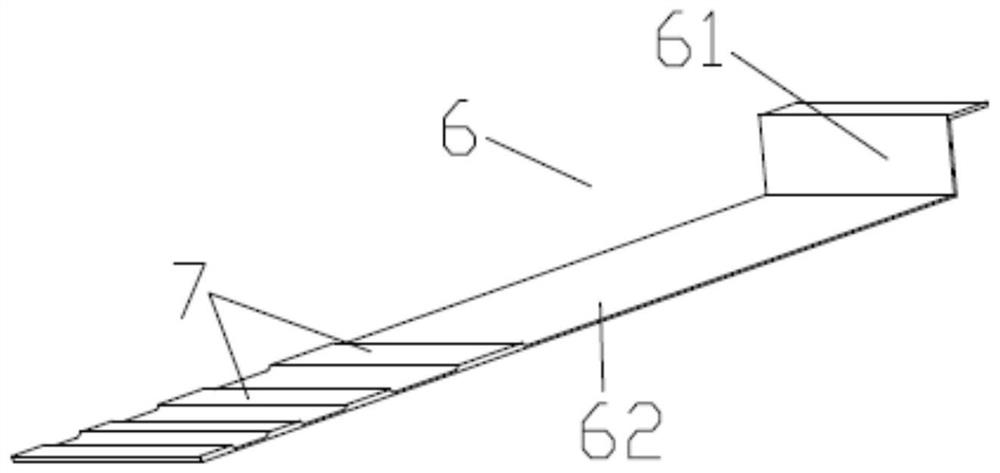

[0037] As an embodiment of the present invention, the material of the target piece 10 is selected as a tungsten target, and the target body 5 is composed of fourteen target pieces 10, and the superimposed surface between every two adjacent target pieces 10 is processed with a working fluid flow gap, The high heat flux area where the eight tungsten targets near the target window 2 is located is provided with an "S"-shaped cooling water channel, the cooling fluid flows in from the fluid inlet 3, and flows through the serial cooling flow near the end of the target window 2 through the drainage channel. The beginning of the channel 8 enters the serial cooling channel 8 to ensure that it is cooled by a single serial flow, while the other six tungsten targets are far away from the target window 2, and the area is a low heat flow area, so it is designed as a parallel cooling channel 9. The cooling working fluid passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com