Hybrid engineering tire vulcanizing machine

A vulcanizing machine and engineering tire technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of environmental protection, high cost, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

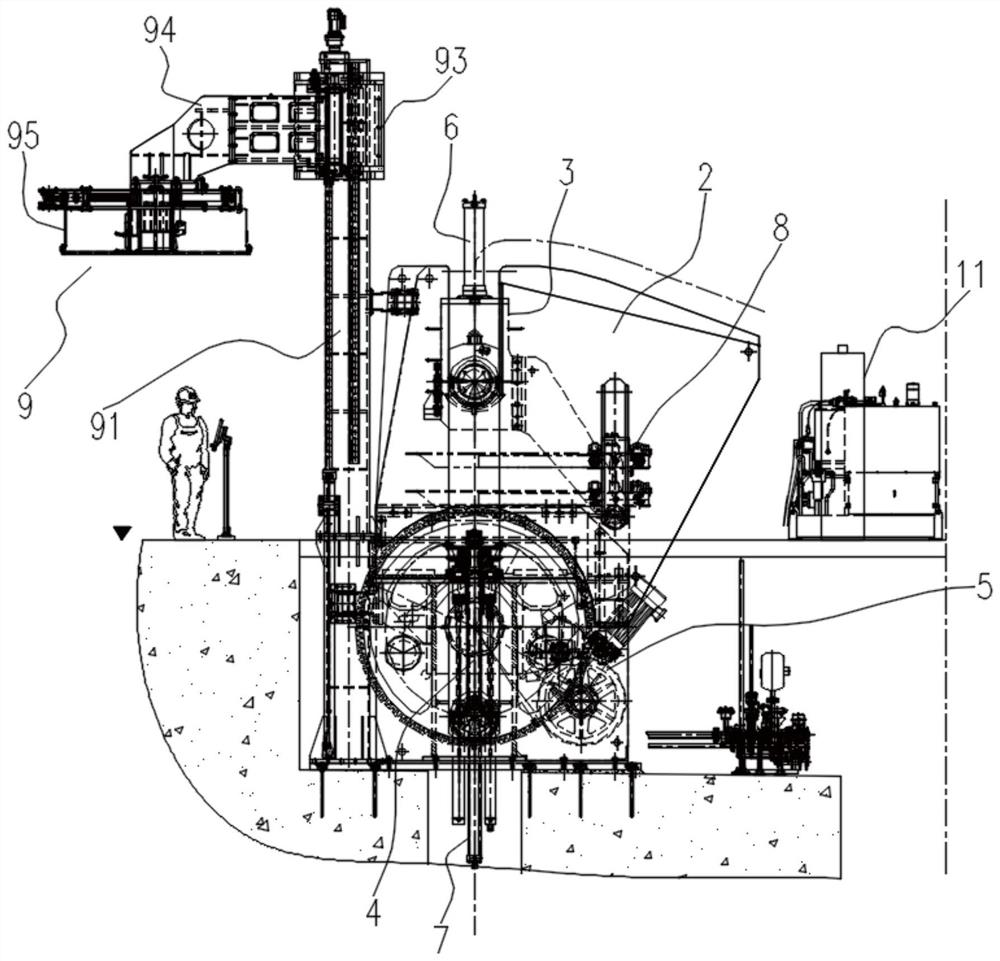

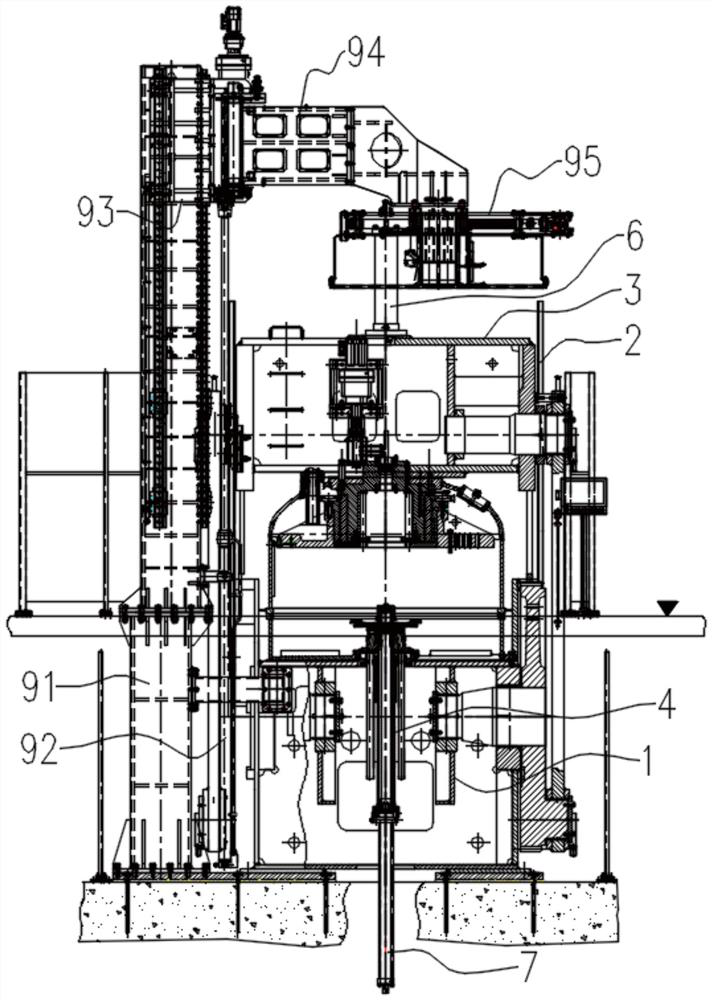

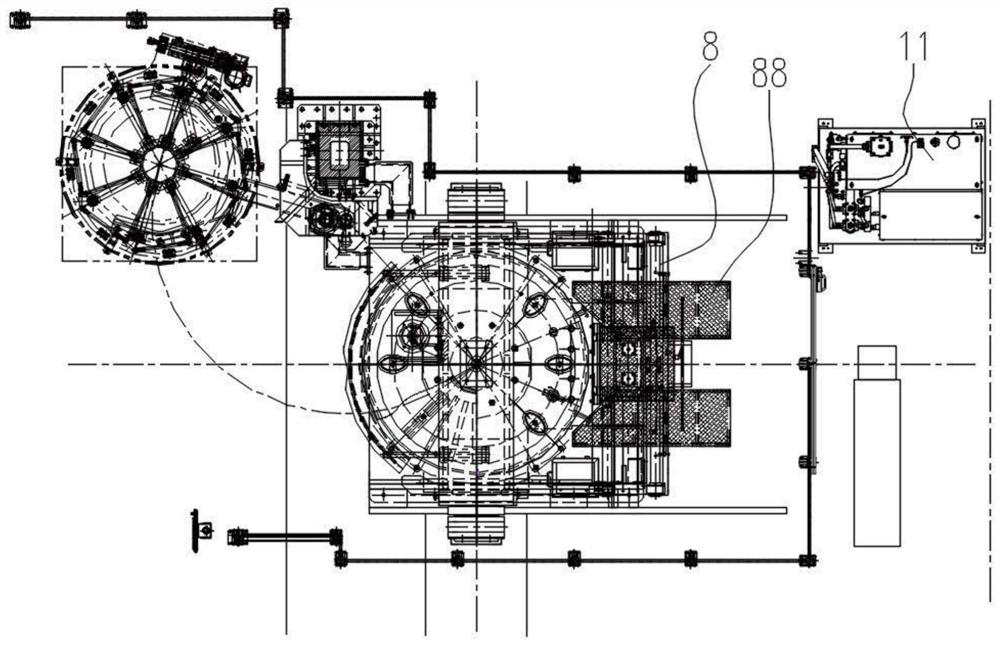

[0052] Such as Figure 1-7 Shown, a kind of embodiment of the present invention is:

[0053] A hybrid off-road tire vulcanizer, comprising:

[0054] base1;

[0055] Two wall panels 2, which are respectively fixed on both sides of the base 1;

[0056] The beam 3 moves along the running track of the wall panel 2 under the drive of the mechanical main transmission mechanism 5;

[0057] Upper mold assembly, which is connected on the beam 3;

[0058] Lower die assembly, which is fixed on the mounting table of the base 1;

[0059] A central mechanism 4, which is installed in the middle of the base 1;

[0060] Mechanical main transmission mechanism 5, which includes main drive motor 51, reduction mechanism 52, transmission gear set 53 and crank linkage mechanism 54, crank linkage mechanism 54 is connected with beam 3;

[0061] The movable mold drives the oil cylinder 6, and its cylinder body is installed on the beam 3, which is used to drive the movable mold to open and close; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com