A hydrogenation catalyst composition and its preparation method

A technology of hydrogenation catalyst and composition, applied in catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc. Low temperature, catalyst carbon deactivation and other problems, to avoid bed temperature flying, increase electronegativity, and protect activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

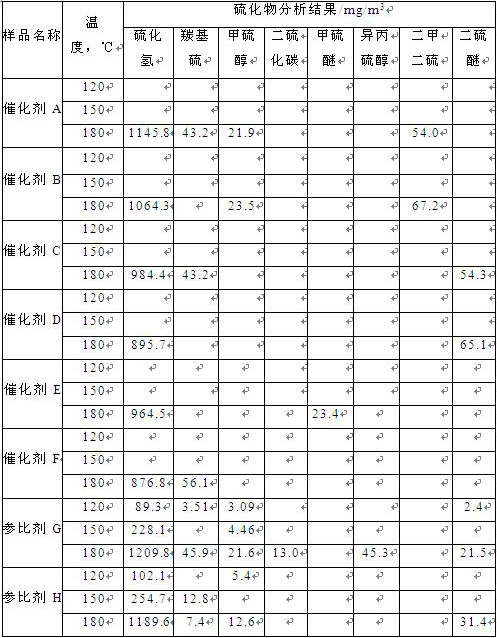

Image

Examples

Embodiment 1

[0025] Take 100g of the oxidized catalyst and spray it with 36g of aqueous solution of 75wt% tetrakis hydroxymethyl phosphorus sulfate, after aging at room temperature for 8 hours, take 20mL of catalytic diesel oil and mix it with it, let it stand for 20min after mixing, take 8g of sulfur powder and mix it again, put The samples were placed in a converter for low-temperature heat treatment. The low-temperature heat treatment conditions were as follows: the temperature was raised to 120°C at a rate of 3°C / min, and the temperature was kept constant for 3 hours. After the sample is cooled, spray the sample with 10ml of hydrazine hydrate, and then put it into a converter for low-temperature heat treatment. The low-temperature heat treatment conditions are: the temperature is raised to 100°C at a rate of 3°C / min, and the temperature is kept at a constant temperature for 3 hours. That is, the hydrotreating catalyst A is obtained.

Embodiment 2

[0027] Take 20mL of coking gasoline and spray 100g of industrially produced oxidized catalyst, mix and let it stand for 20min, take 8g of sulfur powder and mix it again, put the sample into the converter for low-temperature heat treatment, the low-temperature heat treatment condition is: 3°C / min The temperature was raised to 150° C., and the temperature was kept constant for 3 hours. After the sample is cooled, add 36g of 75% aqueous solution of tetrakis hydroxymethyl phosphorus sulfate, and after aging for 8 hours, put the sample into the converter for the second low-temperature heat treatment. , constant temperature for 3 hours. After the sample is cooled, spray the sample with 10ml of hydrazine hydrate, and carry out the third low-temperature heat treatment, and the treatment conditions are the same as the second time. That is, the hydrotreating catalyst B is obtained.

Embodiment 3

[0029]Take 10mL of coking gasoline and 15mL of cottonseed oil, mix and spray 100g of industrially produced oxidized catalyst, mix and stand for 20min, take 8g of sulfur powder and mix it again, put the sample into the converter for the first low-temperature heat treatment, the low-temperature heat treatment condition is : The temperature was raised to 150°C at a rate of 3°C / min, and the temperature was kept constant for 3 hours. Get Tetrahydroxymethylphosphorous Chloride 14g, spray the sample of low-temperature heat treatment for the first time after diluting with 30ml of water, after aging for 8 hours, put the sample into the converter and carry out low-temperature heat treatment for the second time, the low-temperature heat treatment condition is: with 3 The temperature was raised to 120°C at a rate of °C / min, and the temperature was kept constant for 3 hours. After the sample is cooled, 12ml of hydrazine hydrate is used to spray the sample. After spraying, the sample is put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com